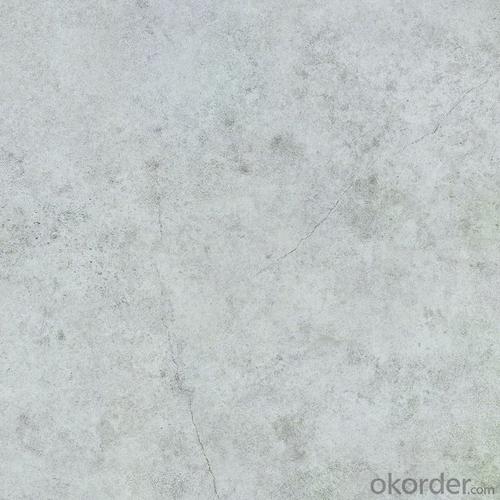

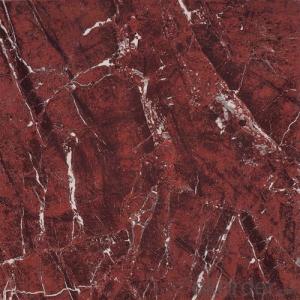

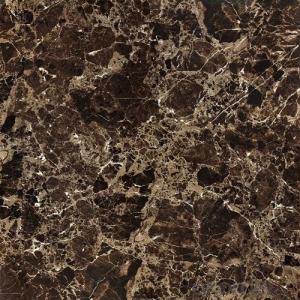

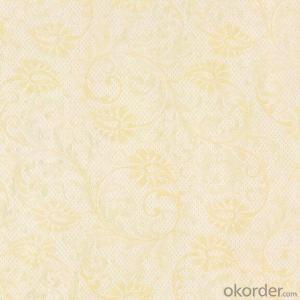

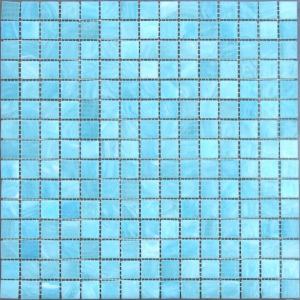

Glazed Porcelain Floor Tile 600x600mm CMAX-TS6005

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 115.2

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Brief Introduction

The glazed porcelain floor tile is wildly popular in Europe, North America and Middle East, and ite could be used for interior floor and wall of Apartment, Villa as well asother areas, due to its unique antirue feel image and terure.The modle NO. CMAX-TS6005 is one of the popular designs in the present market.

Product Features

Excelent glazed surface and porcelain tile body

Grade AAA quality only

The basic size is 600*600mm, which could be cut into 30*60mm, 30*30mm, 15*60mm based on the actual project needs.

Strict quality control system on raw materials selection, kiln temperature, water absorption rate, color shade, deformation, anti-pollution, slip-resistance, abrasion resistance .

Compititive prices

Packing standard: Pater Carton+ Solid Wooden Pallet

Fast production arrangement

OEM service available

Marketing support on samples, catalogues as well as carton designing

Product Specification

Tile Type: Glazed Porcelain Floor Tile

Quality standard: GB/T4100-2006, ISO13006,EN14411.

Water Absorption Rate: 《0.5%

Breaking Strength: 》 1300 N

Length and Width Tolerance: ±0.1%

Surface Smoothness: ±0.5%

Wearing Strength: 《1600 mm3

Slip Resistance: 》 0.5

Packing Information (For 27.5 Tons heavy 20’Fcl)

For 600x600mm, 4pcs/Ctn, 40 Ctns/Pallet, 840 Ctns/20’Fcl, 1209.6m2/20’Fcl

For 300x600mm, 8pcs/Ctn, 40 Ctns/Pallet, 840 Ctns/20’Fcl, 1209.6 m2/20’Fcl

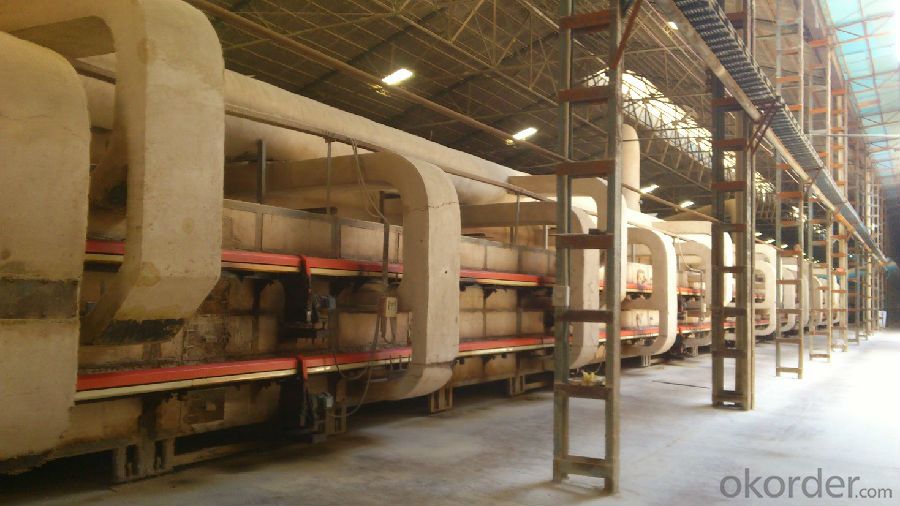

Production Line & Package

FAQ

1. Could you put some samples in the container of our orders?

—— Yes. We’d like to offer free samples in the containers to our clients, with a certain quantity of different models.

2. Could you company supply polished porcelain tile?

—— Yes. We could supply various kinds of polished porcelain tile, with size 60*60, 80*80, 100*100 and 60*120.

3. Can we use the carton with our own design and brand name?

—— Yes. Normally we go with Neutral Carton. If the order quantity is over 5 containers, we could print the carton of client’s design for the final packing.

4. Could we arrange the our own QC to check the items before container loading?

—— Yes, of course. Your quality checking will be welcome all the times.

5. Could we arrange the our own QC to check the items before container loading?

—— Yes, of course. Your quality checking will be welcome all the times.

- Q: I want room color which color perfectly adjust with my granite green tile

- The corporate headquarters of Enterprise Rent a Car have Green granite on the floors and walls. Their leather furniture is a red wine color, and there's also some gold in it. I think other colors would be gold, yellow, tan, and that pallette. Good luck, I hope it comes out well.

- Q: Do you fill up the grout all the way to the top or only upto inner edge? We filled it up to the inner edge, but now the grout and the tile edges are starting to collect dirt very easily and it is very hard to clean. We are thinking of regrouting all the way to the top so that it will be easier to clean. Is that the correct way to grout these tiles?

- Most all tiles ( there are exceptions) are always grouted flush to avoid a couple of things. One is the problem your having now and the other is to protect the edging of the tile.depending on just how much more you have to fill in, you make have to dig some grout out to get a proper bond.. Any questions you can e mail me thru my avatar and check my qualifications there GL

- Q: Bathroom tiles are often encountered in the water dyed ugly color, the market tiles have no waterproof anti-fouling ability?

- In fact, this problem is not difficult, with low water absorption of tiles can be resolved, if not assured, then now some of the brand wall of the wall, basically effective solution to the anti-fouling function, which with the brick itself Water absorption and the thickness of the tile surface glaze

- Q: My granddaughter dropped a hard toy while being held by her Mom. It put a quarter size hole in the center of my ceramic tile. How can I go about filling this hole?

- theres really no way to effectively patch a hole in ceramic,the best way to fix it is to replace it,sorry. repairing a floor tile in a high traffic area such as the kitchen is not a good idea,ceramic has sharp edges when broken and it can and will slice your feet open.I strongly suggest replacing the tile,especially with a little one around.

- Q: Earlier I asked, How to find a good tile? This is what I meant

- Using large tiles are better than the 5 x 5 tiles (old fashioned). Tiles can be marbles or travertine or granite looks more elegant. Normally it sells by 5 - 8 dollars per sq. foot and the labor normally goes the same amount. beware of some contractors that will charge double for the labor meaning... example... 8 dollars per sq foot and they will charge you 16 dollars per sq foot (labor).

- Q: What are the different types of tile and how much of them does it take to cover 1 square foot nad what‘s the cost of them

- i h8 bodhists.

- Q: I have never laid tiles before and I would like to work from the ceiling down. In the shower I am going to use thin set. the rest of the bathroom is green board. which I intended to use a tile adhesive.the reason I wanted to go from ceiling down is I think the layout will look better

- The best way to lay it would... measure from floor to ceiling lets say that its 8 ft. if the tile you are using is 12in then you know that you wild need 8 tiles from floor to ceiling. but you have to add 1/4in gap in the tile or what ever size gap you pick. so with 8 tiles 12ins plus 8 gaps (not counting the top and bottom gaps) you will have an extra 2ins that you have to figure for. It would look really bad if you had to cut the top tile to fit cutting the bottom tile will look much nicer. So the best way to do it is use a spinning laser level to find 2 ins off the floor and mark with black lines. Use nails to hold up your til to that line. Start laying the tile up form that line. Uses spacers to get the gap you would like. side note is that tiles are not all 12 by 12ins some can be as much as 1/4 bigger or smaller than that so if you get a tile like that use a nail instead of a spacer to fit the gap so all the tile are even. your eyes won't see a thiner gap but they will see tiles that aren't even. once you get to the top adjust the spaces to make all the tile nice and even at the top. once your done and the thin set is dry remove the nails holding the bottom tile in place and cut the bottom tile to the size you need. you can't really use the floor as a guild goin up cuz most bathroom floors are slopped and some sides are Higher that others and that will mess you up in you start from the floor up. hope this helps

- Q: I would like to install laminated flooring in my kitchen. Two of the wall are tiled. Is it possible to undercut these tiles or is there an easier method to do a neat installation?

- DO NOT cut the tile. You will crack, chip and split, and potentially ruin much of the tile work. Then you are stuck with a much larger issue. The solution is simple. Lay the laminate right up to the tile. Use quarter round molding (small). If you use wood, paint it to match the tile, floor, or simply paint it an accent color. The molding can be glued into place, thus relieving you of further issues and making the transition beautiful between floor and wall. Tile may also be glued, or use mastic, to place. Then grout. This is, however, a much more expensive option. But, to prevent a potential disaster, it is worth it. The other, simpler resolution, is to lay the tile right up to the tile and seal between floor and wall with a washable silicon. Write to me if you have any questions.

- Q: How to quickly remove the transparent tape on the tiles

- Gasoline or Alcohol! If the best effect of gasoline! Wipe earn

- Q: IAM REDOING MY KITCHEN FLOOR. IS PEEL STICK TILE GOOD FOR THE PROJECT N WILL IT LAST? THANKS

- For most things, in general, you get what you pay for. If you buy the peel and stick tile because it is cheap, then you will have a cheap job. It never sticks as good as the manufacturer says it does. It shows ALL imperfections in the underlying floor surface. You will get goop in the areas between tiles, no matter how well you lay it. It really isn't worth it at all. I did a bathroom and kitchen area in an old house using peel stick tile, and it looked good for about a month, then it turned to crap quickly. I'd suggest either using ceramic tile or a single sheet of linoleum flooring. Good luck.

Send your message to us

Glazed Porcelain Floor Tile 600x600mm CMAX-TS6005

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 115.2

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches