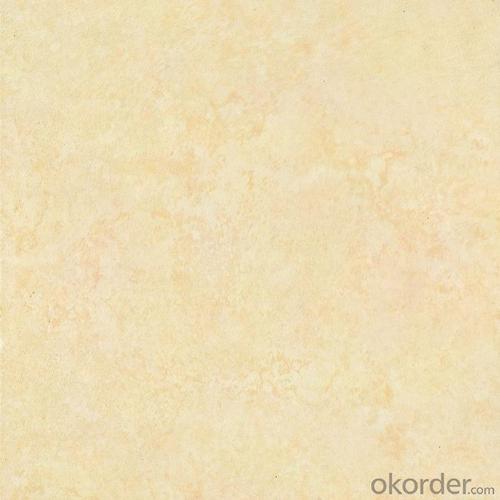

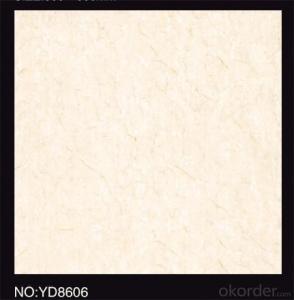

Glazed Porcelain Floor Tile 600x600mm CMAX-TC6025P

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 115.2

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Brief Introduction

Glazed Porcelain Tile CMAX-TC6025P is one of the popular colors in the present market. It could be used for interior floor and wall for apartment, villa, as well as other public areas. Now with the development of production technology and innovation of design, people could get models they like more easily and fast.

Product Features

Glazed Porcelain Floor Tile

Grade AAA available only

Mainly the basic size is 600*600mm, which could be cut into 30*60mm, 30*30mm, 15*60mm, 10*60mm.

Strict quality control system on water absorption rate, color shade, deformation as well as packing.

More competitive prices in China supplying market

OEM service could be offered based on the actual requirement

Professional sales team for the whole purchasing process.

Product Specification

Tile Type: Glazed Porcelain Floor Tile

Quality standard: GB/T4100-2006, ISO13006, ISO9001

Water Absorption Rate: 《0.5%

Length and Width Tolerance: ±0.1%

Surface Smoothness: ±0.5%

Edge Straightness: ±0.5%

Wearing Strength: 《1600 mm3

Slip Resistance: 》 0.5

Resistance to Staining: Class 3.

Packing Information (For 27.5 Tons heavy 20’Fcl)

For 600x600mm, 4pcs/Ctn, 40 Ctns/Pallet, 840 Ctns/20’Fcl, 1209.6m2/20’Fcl

For Packing Standard:Paper Carton + Wooden Pallet

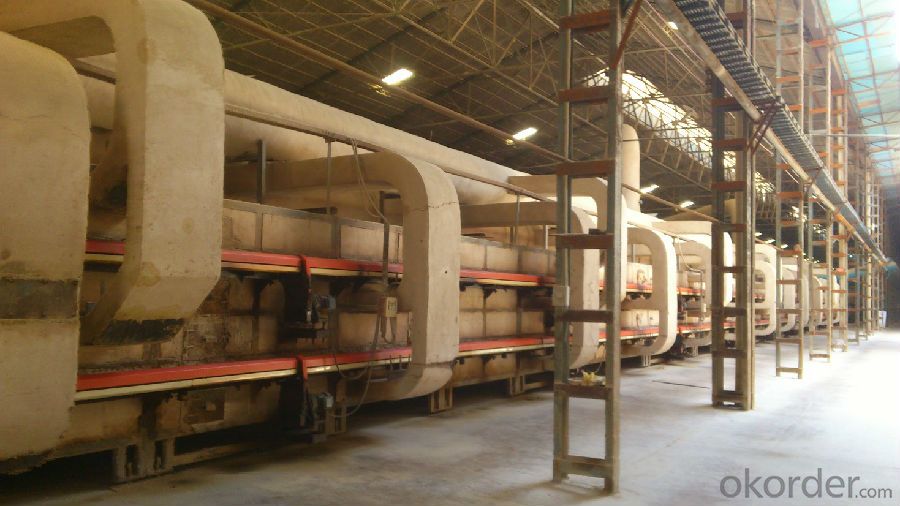

Production Line & Package

FAQ

1. For Glazed Porcelain Floor Tile, what is the difference from polished porcelain tile?

—— For Glazed Porcelain Floor Tile, there is a special glaze layer on the tile surface, which makes the surface feel matt or rough, while the surface of polished porcelain tile is glossy and smooth.

2. What is the delivery time after we paid the deposit?

—— Normally, we shall get all items ready for loading within 3 weeks after we get the deposit or the formal Letter of Credit. For orders which demand cutting job, it will take a longer time.

3. For the delivery term, could you go with CFR our port?

—— Yes, of course. We have very good relationship with those big shipping company, such as COSCO, MSC, HPL etc. We have a very professional logistic team to arrange the shipping issue well.

4. Could you company supply polished porcelain tile?

—— Yes. We could supply various kinds of polished porcelain tile, with size 60*60, 80*80, 100*100 and 60*120.

5. Could you put some samples in the container of our orders?

—— Yes. We’d like to offer free samples in the containers to our clients, with a certain quantity of different models.

6. Could we be your exclusive agent in our country?

—— Possibly. For some countries we are hoping to find a proper partner in working market together. For sure we need to have a good talking for the details.

7. Could we arrange the our own QC to check the items before container loading?

—— Yes, of course. Your quality checking will be welcome all the times.

- Q: What is the best tiles?

- Buddy, you said too general, and here simply say, interior decoration tiles must use all-ceramic tiles, tiles first glass polished tiles (anti-skid, wear, anti-penetration, easy to clean, etc.) (The color of the new, three-dimensional sense of strong, followed by wear) the most sub-microcrystalline stone (expensive, not wear-resistant, non-scratch (The price is high, durable, atmospheric) glazed tiles (the color is more, the price is right, with the most) antique all-ceramic cut on the wall (unique style, durable and durable )

- Q: i need to lcut a circle 36x36 inch on floor tile thats about 1/2 inch thick. can dremel cut this? thanks

- Depends on the exact type of tile. Some porcelain and other hard bodied tile you ll burn the bits and possible the motor itself. If it was a smaller area you had to cut out, it would possible work. Some satillo tiles you could do this with some extra bits , since they are a softer bodied tile. Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q: Or can I just start tiling over the painted wall?

- I can't believe I, as the lone female answering, am going to have the right answer. Yes, you need backerboard. Simply put, you are tiling. Have you ever lifted a box of those tiles? And can you imagine one of them on that wall? Now, how about 10 of those boxes? You see, you are putting up tile and tile cement and tile group, all very heavy items, onto what may well be simple sheetrock. Yes, you need backerboard. Specifically, you want cement board, which is specifically designed to be used with tile and be waterproof. You see, in your zest to prove you can do it, you may well have a moisture issue come from an overlooked mistake in the tiling. Maybe it's the caulk at the tub seal, maybe it's in a corner, maybe it comes from an awkward merging of two tiles. Whichever it may be, you want a waterproof surface which will stay intact from such an issue ... sheetrock, no matter how nicely painted prior, simply won't do that. Yes, you need cement board. Ask anybody at your local home center if you doubt me ... and I, as the lone female, will now bid adieu.

- Q: if there are 24 square tiles in a box and there are enough to cover 3 square feet, how big are the tiles?

- 24 tiles/3 sq ft =8 tiles per square foot. Since 8 is not a square, there is no solution, or the tiles cannot be square.

- Q: Why the tile is not clean clean

- To the hardware store to buy a bottle of hydrochloric acid, industrial used those, more than two, even when cleaning is not careful to get the hands of no problem, and to ensure that your tiles bright as new.

- Q: Can I use talavera tiles for this? The porch is concrete and was painted at one time. Looks like the last owners removed the paint, but then left it as is. Is talavera tile ok to use on an outdoor porch. I don‘t know much about it, I‘ve only seen pictures and think it‘s beautiful! Thanks!!

- any tile you like is okay to use. my advice would be to prepare the surface by cleaning it thoroughly then using a concrete adhesive before setting your tile with white thinset mortar. after grouting , be sure to use a sealer to prevent moisture getting under the tiles. the sunlight will expand the water and cause vaporlock that will pop your tiles. then maintain by resealing at least once ayear.

- Q: Does the tiles have radiation?

- As long as the tile is fired without radiation Another: home is not recommended with natural stone, including your windowsill, over the beam, countertops and other positions. Comrades also say that point, lesbian may have no children in this life said No way to buy a wooden floor, in fact, pure concrete floor is not ugly, wipe, and very effective, get hold of a modern design Kazakhstan Understand your feelings, do not worry, if you really do not worry, find a mechanism to detect it

- Q: I need some tiles to replace on my roof. They type of tile, I‘m told is Santa Rosa tile and is made from a reddish orange color clay, does anyone know where to get this type of tile in central California?

- Tile roofs are far more common in your part of the country than they are in mine. Your best bet is to look for roofing supply businesses in your local yellow pages. If it turns out to be impossible to get the exact same tile, a substitute can always be found. If the tiles you need replaced are on a highly visible part of the house, consider removing tiles from another part of the house to make the repair match, and use the new tiles in the less visible area. Good luck with your repair.

- Q: We have small ceramic tiles on our bathroom floor. They are varied in shape and size (see photo).I think that these tiles originally came with some sort of netting on the back when they laid the floor and they added grout? I believe I saw some extra tiling somewhere in our home and this is what I had found.Anyway, the grout is breaking up between some of the tiles and some of the tiles keep popping out. I have two questions, If I regrout them do I put it on the bottom of the tile too and does that make the tile adhere to the floor?How would I get the grout to match what‘s already there, it‘s a medium brown gray. Not sure if it started out that way or became like that over the years. Would it look funny if the grout didn‘t match? How could I get it to match?

- I okorder /

- Q: just had a tile floor laid and i noticed some were higher than the one next to it in about 6 tiles. my husband says every house will have those. does yours?

- Having the tiles uneven on a new installation is not right. Couple reasons to cause this and should have been caught by the installer.They are more than likely not loose but since they are uneven, your more than likely to chip the edges over time. Get the installer back and have it fixed. Tile should be perfectly flat. Any questions you can e mail me through my avatar and check my qualifications there. GL

Send your message to us

Glazed Porcelain Floor Tile 600x600mm CMAX-TC6025P

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 115.2

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches