Glazed Porcelain Floor Tile 600x600mm CMAX-A6011

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 115.2

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Information:

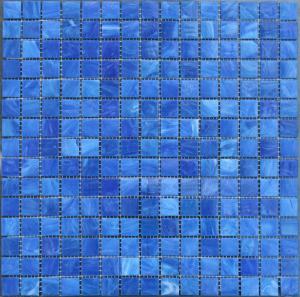

Tile Type | Glazed Porcelain Tile, floor tiles |

Certificate | ISO13006, ISO9001 |

Finish | Matte Finish, Lapato Finish, Rough Finish |

Size | 60x60 mm |

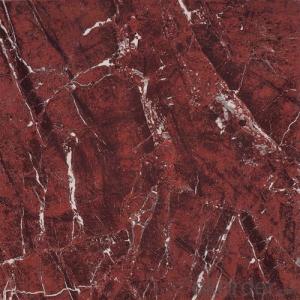

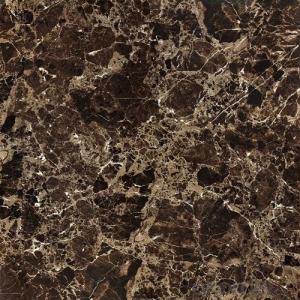

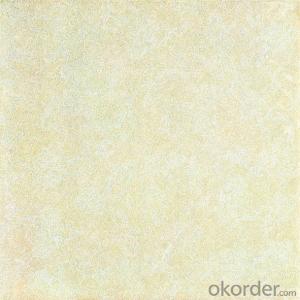

Selection Range | Several Colors available |

Features:

1) Unique natural sandstone image designs and exclusive quality;

2) Used for indoor & outdoor wall and floor decorations, as well as Stair Case Product;

3) Easy to install, anti-dust, washable, acid-proof, alkali-proof, durable

4) Material: porcelain

5) Basic size: 600x600x9.8mm, 100x600mm, 150x600mm, 300x300mm, 300x600mm available based on clients’ requirements;

6) Available dimensions

Material | Porcelain |

Dimension | 600x600x9.8 mm |

Packing | Carton + Wooden Pallets |

Finish | Glossy, over 90 degree. |

Usage | Floor and wall |

The glazed porcelain tile is widely used for interior house flooring, hotel lobby flooring, exclusive brand showroom, clubs villas as well as other public sites.

We could go with OEM model, making 2nd production based on client’s requirement;

We could offer flexible service on shipment and better support on payment term;

Our quality guarantee is based on the strict production procedure, quality controlling on the shade, straightness as well as 2nd production and final package.

Specification and technical parameter:

· Matte Finish, Lapato Finish, Rough Finish

· Water absorption:<0.1%< span="">

· Anti-Resistance: R10

· Delivery Time: within 15~20 days after order confirmation.

· Package standard: 4pcs/carton, 40 Cartons/pallet, 32 Kgs/Carton.

- Q: It has been installed on a concrete slab for about five months now, could the slab not have cured right or is the tile layed wrong?

- probably there was dirt or something under the tile proir the installation. or the adhesive was not put on properly. you will need to remove the tile, clean the floor completely and re install, and re grout.

- Q: Have you used the marble tiles, the quality, the price?

- In the choice of floor tiles, the focus should be considered such a few aspects: First, look at the brand. Only the well-known brands of floor tiles, the quality of its building materials to meet the national standards, the content of harmful substances in the safe range. Second, to see its anti-fouling ability, if the family are very busy, two or three days to clean a health, it would choose to better defrost capacity. Third, if the home has the elderly and children, then the purchase must be made about non-slip test.

- Q: Do you have to rough up the old flooring ?

- Maybe. If the old vinyl tile is flat, then yes. If it is dimensional (has any type of raised surface), then you would have to use a flooring patching compound to level it (a lot of work). Also, you have to make sure the old vinyl tile is clean. Glue will not stick to a dirty surface. I would think it would be easier to get thin plywood, nail it down and put the vinyl tile on that.......

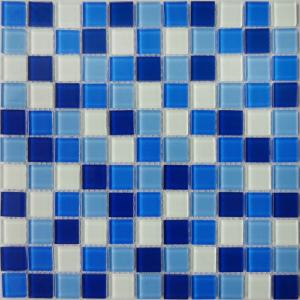

- Q: I‘m thinking about having a bathroom tiled. The bathroom is about 6 by 8 and right now the walls have a horrible pink and black alternating ceramic tile that goes up about 4 feet on the wall all the way around. All I want to do is replace this tile with a glass tile. I have no idea what the cost would be for materials and labor so any estimates would be appreciated. This is the only work I need done.

- Removing old tile and backer board, replace with new backer board and new tile with average tile and size $5000 to $10,000. With glass tile and special setting material for the glass tile about 2 to 3 times the above. The best way is to shop at a tile or flooring store to get a real price for your area as price vary by regent. If possible get the material and installation from the same place.

- Q: Should I put in a ceramic tile shower or cultured marble shower? Which would provide a better return when selling the house?

- Tile looks great but is a real problem to keep mildew free. We lived in Houston for 20 years and had a tiled shower, it was a constant battle. We now have a cultured marble shower. Mildew is not a problem. I would not have any other type of shower. It is always clean and just a little spray with one of those new spray products and there is no soap scum to deal with either. It is less likely to have leak problems as well. If you are going to live in the house for a while, go with the cultured marble.

- Q: I am thinking about tiling 2 bathrooms in a rental property and planning to use 12x12 tiles costing $1 each. I want to use the same tiles for bathtub surrounds as well as floor. I am looking for some advice about the size of tiles that may be appropriate.Thanks

- I built my entire shower, floor, wall, and even ceiling with 12x12 looks great, but you have to be patient on the walls, and ceiling. I have put many 12x12's on the walls of tubs. Make sure you use something for the spacers for the wall or they will slide down. A thin strip of 3/8 plywood works great. If you ever put them on a ceiling you have to use screws with large washer, and glue. You can take the screws out once the glue is cured. To grout a ceiling you have to use silicone caulk and then dust the grout let dry and then seal. Makes for one cool looking bathroom.

- Q: I ripped up all the existing tile, it was small tiles that I had to chisel up. There is quite a bit of thinset that is bonded to the wood floor and its impossible to get it all up. If I try and chisel it all off I end up ripping up the wood and making it worse.I think the wood sub floor is sitting on another older piece of sub floor but i‘m not sure.What are my options here?- put cement board over it (do i need to put waterproof membrane?) and then tile it? If I do this the bathroom floor will be slightly higher then the hallway floor.- Can I use self leveler on the wood subfloor and then tile over it? it would probably be the ideal height.- Do I chance ripping up the subfloor and doing cement board and then tile?Am I missing any other options?

- Cut okorder /

- Q: Hi, I am thinking about placing vinyl wood planks over the existing ceramic tile in my house and I wanted to know if it‘s possible. The tile isn‘t completely level due to the grout and obviously not all the tiles are exactly the same height down to the millimeter. I wanted to know 1. Is it possible to install vinyl wood plank over ceramic tile, 2. If so how level the tile floor has to be, 3. How would I go about leveling the floor, with an underlayment or with some sort of mortar, 4. If I use an underlayment do I still need to use the mortar to level the tile?Thank you.

- While its always best to remove the tile and start with a fresh base for a new sub floor for the vinyl tile. This can be done .. You need to go over the tile with whats called an embossing leveler.. This will allow the vinyl to not show the grout lines. The high spots can be knocked down or floated so its barely noticeable. . By the time you do all this and the chance that you don t get any uneven tile floated out, your better off taking every thing out and do it proper. Any questions you can e mail me through my avatar. GL

- Q: Recently want to decorate the house, in addition to the location of the two bedrooms have to shop porcelain, ask the tiles below can be installed to warm it? Will the heating effect be discounted? Can you install the bathroom in the bedroom and warm in another room? How much will the ground increase after loading Thank you first!

- It is best not to install. Because the ceramic is insulated, if installed, it may affect the heating effect. Recommended to install heating, and is plumbing, if it is warm, the indoor easy to dry, I wish you a beautiful house decoration.

- Q: I found answers about laying tile and a backer board over linoleum I didn‘t know if they would be the same. What would cause tile to crack if it‘s places directly on concrete?

- do not lay ceramic tile over vinyl, vinyl moves. Ceramic does not and will crack

Send your message to us

Glazed Porcelain Floor Tile 600x600mm CMAX-A6011

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 115.2

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches