Glass Wool Insulation Glass Wool Insulation Manufacturers

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Blanket:

Rockwool products have many practical uses; the following are some of the main fields:

In the Thermoacoustical field Rockwool is used for the insulation of buildings of all types and uses, such as houses, department stores, offices, athletic buildings, airports, etc.

In insulating industrial plants buildings and mechanical systems like:

Cooled stores.

Refineries.

Chemical and Petrochemical Plants.

Central Air conditioning.

Hot water and chilled water systems.

For industrial purposes, Rockwool is used in many industries as:

Industrial furnaces and ovens.

Boilers.

2.Main features of Glass Wool Blanket:

1) High temperature heat-stability, durability, high temperature shrinkage resistance

2) Damp proof property, with the hydrophobicity are not less than 98%

3) Excellent fire proof performance, European standard non-flammable class A material

4) Non-poison, not contain rock wool and doesn't grow the mould etc.

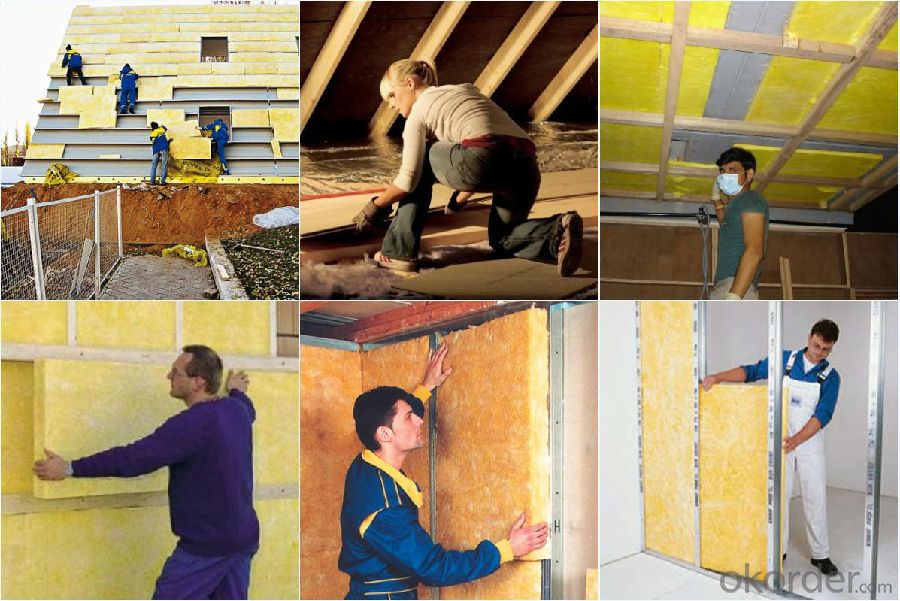

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How is fiberglass mat tissue used in the production of windshields?

- The unique properties and functions of fiberglass mat tissue make it a crucial component in windshield production. To strengthen and increase the durability of the glass, manufacturers use fiberglass mat tissue as a reinforcement material. In the manufacturing process, a layer of fiberglass mat tissue is inserted between two layers of glass to create a laminated structure. This layer acts as a barrier, preventing the glass from shattering upon impact and holding it together for the safety of the vehicle occupants. By serving as a reinforcing material, fiberglass mat tissue improves the mechanical properties of the windshield. It enhances the impact resistance, reducing the likelihood of cracks or chips caused by stones, debris, or other objects. This reinforcement also provides structural integrity, allowing the windshield to withstand extreme weather conditions and vibrations without affecting its functionality. Moreover, fiberglass mat tissue aids in reducing noise transmission and vibrations. Its sound-damping properties contribute to a quieter and more comfortable driving experience by minimizing external noise from entering the vehicle cabin. Additionally, the use of fiberglass mat tissue enables the production of curved windshields. The material's flexibility allows it to conform to different shapes and contours, enabling manufacturers to create windshields with customized designs and improved aerodynamics. In conclusion, fiberglass mat tissue plays a vital role in windshield production. Its reinforcement properties enhance the strength and impact resistance of the glass, ensuring the safety of vehicle occupants. It also contributes to a quieter driving experience and enables the production of curved windshields with improved aerodynamics.

- Q: What is the tear resistance of fiberglass mat tissue?

- The tear resistance of fiberglass mat tissue refers to its ability to withstand tearing or ripping when subjected to mechanical stress or force. Fiberglass mat tissue is known for its high tear resistance due to its strong and durable nature. The tear resistance of fiberglass mat tissue is typically measured and reported in terms of its tear strength, which is a measure of the force required to tear the material. This tear strength is determined through standardized testing methods, such as the Elmendorf tear test or the tongue tear test. The tear resistance of fiberglass mat tissue can vary depending on factors such as the thickness, density, and composition of the material. However, overall, fiberglass mat tissue is known to have excellent tear resistance properties, making it an ideal choice for applications where durability and strength are required, such as in the construction industry for reinforcing materials or in the manufacturing of composite materials.

- Q: How is fiberglass mat tissue used in the production of composite panels?

- Fiberglass mat tissue is commonly used in the production of composite panels due to its unique properties and versatility. It serves as a reinforcement material that helps enhance the strength, durability, and overall performance of the composite panels. In the production process, fiberglass mat tissue is typically sandwiched between layers of resin to create a composite structure. The tissue acts as a reinforcing layer, providing additional strength and stability to the panels. It helps distribute the stress applied to the panel evenly, reducing the risk of cracks or fractures. One of the key advantages of using fiberglass mat tissue is its ability to improve the impact resistance of composite panels. The tissue absorbs and disperses energy when subjected to external forces, minimizing the risk of damage or breakage. This makes it an ideal choice for applications that require high impact resistance, such as automotive parts, boat hulls, or aircraft components. Fiberglass mat tissue also offers excellent corrosion resistance, making it suitable for use in environments with high humidity or exposure to chemicals. It acts as a barrier that protects the composite panels from moisture and corrosive substances, extending their lifespan and ensuring their long-term performance. Additionally, fiberglass mat tissue is highly moldable, allowing for the creation of complex shapes and designs. It can be easily molded into various forms, providing flexibility in the production process and enabling the creation of customized composite panels for specific applications. Overall, fiberglass mat tissue plays a crucial role in the production of composite panels by reinforcing the structure, enhancing impact resistance, improving corrosion resistance, and enabling flexibility in design. Its unique properties make it a popular choice in industries such as construction, transportation, aerospace, and marine, where high-performance and durable composite panels are required.

- Q: What is the tear strength of fiberglass mat tissue?

- The ability of fiberglass mat tissue to resist tears or cracks when exposed to external forces is referred to as its tear strength. This characteristic plays a crucial role in determining the durability and performance of fiberglass mat tissue in different applications. Standardized testing methods, such as the ASTM D1922 tear resistance test, are typically used to measure the tear strength of fiberglass mat tissue. This test involves applying a controlled force, usually in the form of a tensile load, to a sample of the material and measuring the amount of force required to cause a tear or rupture. The tear strength of fiberglass mat tissue can vary depending on factors such as the manufacturing process, the quality of the raw materials used, and the specific requirements of the application. Generally, fiberglass mat tissues are designed to have high tear strength in order to withstand the stresses and strains encountered during installation and use. Fiberglass mat tissue finds widespread use in industries like construction, automotive, aerospace, and marine, thanks to its high tear strength and other desirable properties. It is commonly employed as a reinforcement material in composites, providing increased strength and durability to the final product. In summary, the tear strength of fiberglass mat tissue is a vital property that determines its ability to resist tearing or cracking when subjected to applied forces. By ensuring a high tear strength, fiberglass mat tissue can meet the demands of various applications and deliver long-lasting performance.

- Q: What is the expected lifespan of fiberglass mat tissue in chemical storage applications?

- The expected lifespan of fiberglass mat tissue in chemical storage applications can vary depending on factors such as the specific chemicals being stored, the conditions of storage (temperature, humidity, etc.), and the quality of the fiberglass material. However, fiberglass mat tissue is generally known for its durability and resistance to corrosion, making it suitable for long-term use in chemical storage applications. With proper maintenance and care, it can typically last for many years.

- Q: How does fiberglass mat tissue perform in terms of thermal resistance?

- Fiberglass mat tissue generally performs well in terms of thermal resistance. The mat's composition, which typically includes glass fibers, helps to provide insulation and protection against heat transfer. This makes fiberglass mat tissue an effective material for applications where thermal resistance is desired, such as in the construction industry for insulation purposes or in the manufacturing of heat-resistant products.

- Q: Is fiberglass mat tissue resistant to acids?

- Yes, fiberglass mat tissue is generally resistant to acids. Fiberglass is known for its excellent corrosion resistance properties, and this includes resistance to various acids. The combination of fiberglass mat and resin creates a strong and durable material that can withstand exposure to a wide range of chemicals, including acids. However, it is important to note that the specific type and concentration of acid can still affect the resistance of fiberglass mat tissue. In some cases, certain highly concentrated or aggressive acids may cause damage or degradation to the material over time. Therefore, it is always advisable to consider the specific acid being used and consult the manufacturer's recommendations for compatibility before exposing fiberglass mat tissue to any acidic environment.

- Q: Can fiberglass mat tissue be used for composite panel manufacturing?

- Composite panels can be manufactured using fiberglass mat tissue, a thin and lightweight material composed of randomly oriented fiberglass strands bonded with a binder. This material is commonly employed as a reinforcement in composite manufacturing processes. In composite panel manufacturing, fiberglass mat tissue is typically mixed with other materials such as resin and a core material. This combination results in a robust and long-lasting panel. The mat tissue reinforces the panel, ensuring the distribution of loads and preventing cracking or delamination. Fiberglass mat tissue is renowned for its exceptional tensile strength, dimensional stability, and resistance to chemicals. These qualities make it highly suitable for use in composite panel manufacturing across various industries, including construction, transportation, marine, and aerospace. In summary, fiberglass mat tissue is a versatile and efficient material that can be effectively utilized in the production of composite panels. Its properties and characteristics make it a dependable choice for creating sturdy and enduring panels for diverse applications.

- Q: Can fiberglass mat tissue be used for insulating metal buildings?

- Yes, fiberglass mat tissue can be used for insulating metal buildings. It is a commonly used insulation material due to its excellent thermal properties and ability to resist heat transfer.

- Q: What are the different types of fiberglass mat tissue available in the market?

- There are several types of fiberglass mat tissue available in the market, including chopped strand mat (CSM), continuous filament mat (CFM), and surfacing mat. Chopped strand mat is made up of randomly oriented short glass fibers held together with a binder, providing good strength and conformability. Continuous filament mat consists of long continuous glass fibers, providing higher strength and stiffness. Surfacing mat, on the other hand, is a thin layer of fiberglass mat used to improve the surface finish and appearance of the final product.

Send your message to us

Glass Wool Insulation Glass Wool Insulation Manufacturers

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords