Silica Brick for Glass Furnace Application

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.high temp Refractoriness Under Load

2.good stability under high temp

3.low pollution

4.Refractory Silica Brick

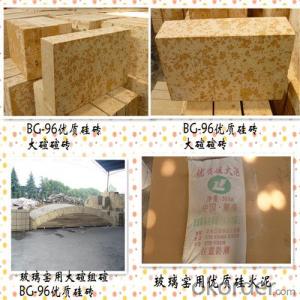

Silica Bricks for Glass Furnace

,there are series silica bricks for glass furnace, BG-95, BG-96A, BG-96B. high purity silica for brick mading, with science material proporation and technic of products. different calcined machine, automation, short cycle of production.

Item | BG-94 | BG-95 | BG-96A | BG-96B | |

Chemical composition | SiO2 | ≥94 | ≥95 | ≥96 | ≥96 |

Fe2O3 | ≤1.5 | ≤1.5 | ≤0.8 | ≤0.7 | |

Al2O3+TiO2+R2O |

| ≤1.0 | ≤0.5 | ≤0.7 | |

Refractoriness °C | 1710 | 1710 | 1710 | 1710 | |

Apparent Porosity% | ≤22 | ≤21 | ≤22 | ≤22 | |

Bulk Density g/cm3 | ≥1.8 | ≥1.8 | ≥1.8 | ≥1.8 | |

True Density,g/cm3 | ≤2.38 | ≤2.38 | ≤2.34 | ≤2.34 | |

Cold Crushing Strength Mpa | ≥24.5 | ≥29.4 | ≥35 | ≥35 | |

0.2Mpa Refractoriness Under Load T0.6 °C | ≥1630 | ≥1650 | ≥1680 | ≥1680 | |

Permanent Linear Change On Reheating(%)1500°CX2h | 0~+0.3 | 0~+0.3 | 0~+0.3 | 0~+0.3 | |

20-1000°CThermal Expansich10-6/°C | 1.25 | 1.25 | 1.25 | 1.25 | |

Thermal Conductivity (W/MK) 1000°C | 1.74 | 1.74 | 1.44 | 1.44 | |

- Q: The introduction of silica brick

- The silica mineral phase is mainly composed of tridymite and cristobalite, there is a small amount of quartz and glass

- Q: Because of the recent relates to this industry, by way of learning to name for all raw materials, I hope knowledgeable friends exhibitions, thank you.

- The main raw material is the main body of refractory. Auxiliary raw materials can be divided into binders and additives. The role of bonding agent is to make the refractory body in the production and use process has enough strength. There are commonly used lignin, phenolic resin, asphalt, cement, water glass, phosphoric acid and phosphate, sulfate, some main raw material itself has the effect of binder, such as clay; additive is to improve the production of refractory materials and construction technology, or strengthen the refractory material of some properties, such as stabilizer, water reducing agent, inhibitor, plasticizer, foaming agent, dispersing agent, bulking agent, antioxidant.

- Q: Why will expand when heated brick

- In the process of SiO2 drying, the four crystalline transformation points of 117, 163, 180~270 and 573 DEG C are found, among which the volume expansion caused by the 180~270 is the largest.

- Q: What is the effect of the content of silicon nitride in silicon nitride bonded silicon carbide brick on the use of electrobath? Thank you

- Small fluctuations in the chemical composition do not have a significant effect on use. The key is the operation of the electrolyzer in production to determine whether the side wall will be damaged.

- Q: Such purpose and scope please give me detailed points thank you because I am learning stage

- Mainly used for coke oven carbonization chamber and the combustion chamber wall, open hearth furnace regenerator and a sediment chamber, soaking furnace, glass furnace, refractory materials and ceramic brick kiln, kiln vault and other load-bearing parts. Also used for high temperature bearing part of hot blast stove and acid open hearth furnace.

- Q: What is the main material of silica brickIt's common, the kind we see so often!

- An acid refractory consisting mainly of quartz and square quartz and a small amount of residual quartz and glass.

- Q: Glass kiln brick for physical and chemical indicators?

- Glass kiln with high quality silica brick products according to the standard JC/T615-1996, the single brick is divided into 3 grades: XBG-96, ZBG-96, DBG-96.

- Q: Can iron oxide be used as refractory material?

- Is widely used in this area. Mentioned refractory material of high school textbooks generally refers to three two aluminum oxide (alumina), alumina is also used as a refractory material, refractory crucible, porcelain, artificial gemstones.

- Q: The chemical composition of silica brick and its physicochemical index?

- The physicochemical index of silica brick:Turn left to |

- Q: The difference between clay refractory bricks and refractory brick in the application.

- Brick bearing soft temperature and close to the melting point, high temperature strength, can be in high temperature (above 1400 degrees) under the condition of long-term use, but the anti alkali erosion ability, thermal shock stability is the worst, a scrap. The brick is generally used in the coke oven, glass kiln. Other industries basically do not use.

Send your message to us

Silica Brick for Glass Furnace Application

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords