Silica Brick for Light Weight Glass Furnace

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

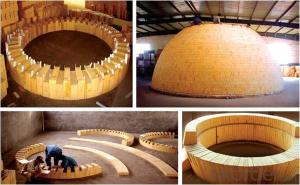

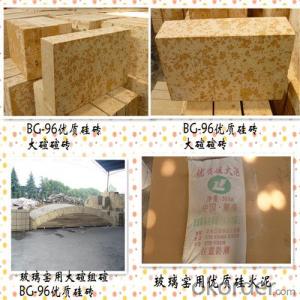

The silica brick can be widely used in coke oven, hot blast furnace, glass furnace and carbon furnace. In glass industry, it is mainly employed to build the doghouse crown, suspended wall of channel, top crown and inlet sealing. In metallurgy industry, it is adopted as the nozzle brick

Features

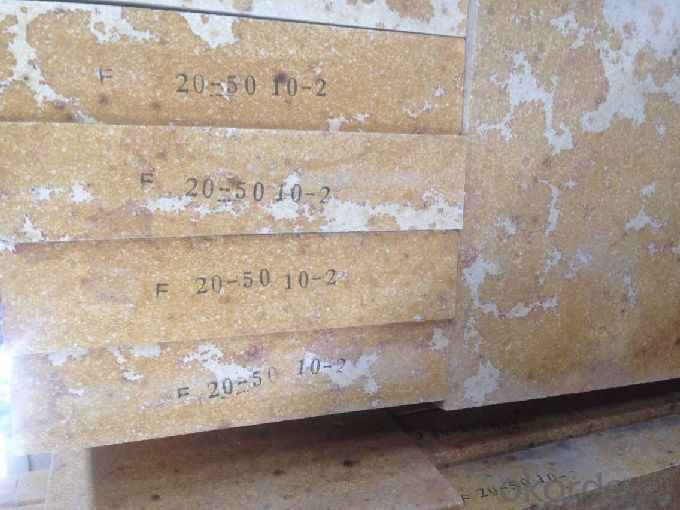

Light weight fused silica refractory for hot blast furnaceWith dense and smooth appearance, uniform corner and edge, pure color and luster and accurate size

1)Good acid erosion resistance.

2) High softening point with temperature.

3) No shrink in burn repeatedly.

Stable Capability, High Quality, Excellent Service, Competitive price is the most important advantage of our products

Applications:

Light weight silica bricks are primarily used for furnaces and kilns in metallurgy, steel, power, chemical industry, and electric power and machine building etc areas

Physical & chemical indexes

Item Brand Index | Light weight silica brick |

QG-1.2 | |

SiO2≥ | 91 |

Refractoriness | 1670 |

RUL(0.2 MPa)T1, °C | 1560 |

Apparent Porosity%≤ | ≥45 |

Cold Crushing Strength Mpa ≥ | 3.5 |

True Density g/cm3 ≤ | 2.39 |

Bulk Density g/cm3 ≤ | 1.20 |

Our factory product various kinds of refractory products. The products can be made according with the customers' requirement

- Q: Because of the recent relates to this industry, by way of learning to name for all raw materials, I hope knowledgeable friends exhibitions, thank you.

- Acidic materialMainly siliceous materials, such as quartz, tridymite and cristobalite, chalcedony, flint, opal, white quartzite, silica sand, diatomaceous earth, silicon oxide contained in these siliceous materials (SiO2) at least 90%, pure raw materials are silicon oxide as high as 99% or more. Siliceous materials at high temperature is the acidic nature of chemical dynamics, when the presence of metal oxide, or when in contact with the chemical reaction, and combined with a fusible silicate. Therefore, if there is a small amount of metal oxide in siliceous material, it will seriously affect its thermal resistance.

- Q: The specific content is what gb/t2608-2012 brick

- The provisions of the brick classification, technical requirements, test methods,

- Q: What is acid refractory?

- Acid refractory material usually refers to refractories with SiO2 content greater than 93%. Its main characteristic is that it can resist acid slag corrosion at high temperature, but it is easy to react with alkaline slag.

- Q: What is the main material of silica brickIt's common, the kind we see so often!

- Higher high temperature strength. The softening start temperature is 1620~1670 degrees. Long term use at high temperature without deformation. The thermal shock resistance is low (the heat exchange in water is 1~4 times). The natural silica is used as the raw material, and a proper amount of mineralizer is used to promote the transformation of quartz into phosphorus and quartz. Slowly sintered at 1350~1430 DEG C in the reducing atmosphere. When heating up to 1450 degrees, the total volume of 1.5~2.2% expands, and the residual expansion can close the kerf and ensure the airtight and structural strength of the masonry.

- Q: Semisilica brick, clay brick, high alumina brick and what is the difference?

- The share of A12O3 and SiO2 is different

- Q: Can iron oxide be used as refractory material?

- Is widely used in this area. Mentioned refractory material of high school textbooks generally refers to three two aluminum oxide (alumina), alumina is also used as a refractory material, refractory crucible, porcelain, artificial gemstones.

- Q: The high thermal conductivity of silica brick and traditional brick what is the difference?

- Brick, high thermal conductivity has been greatly improved in terms of morphology, crystal structure, physicochemical index. The structure and morphology of high thermal conductivity of silica brick,Structure and morphology of high thermal conductivity and the traditional brick brick magnified 20 times were compared, high thermal conductivity silica pore size distribution is more uniform and finer.

- Q: Can not use it two brick

- Acidic silica brick refractory material, has good ability in acid slag erosion

- Q: Brick

- The silica mineral phase is mainly composed of tridymite and cristobalite, there is a small amount of quartz and glass. Tridymite and cristobalite and quartz remaining at low temperature due to phase change, volume changes greatly, so the brick thermal stability at low temperature is very poor. In use, under 800 degrees Celsius, slowly heating and cooling, so as not to produce cracks. The use of temperature in blast furnace so should not be below 800 DEG on.

- Q: Why is the highest brick coke oven temperature measuring point temperature not exceeding 1450

- Brick belongs to refractory materials, with strong resistance to acid slag or acid solution erosion ability, high load softening temperature are excellent properties of silica brick, usually 1640-1680 C.

Send your message to us

Silica Brick for Light Weight Glass Furnace

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords