Geotextile Fabric Staples Woven PP Earthwork for Road Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details

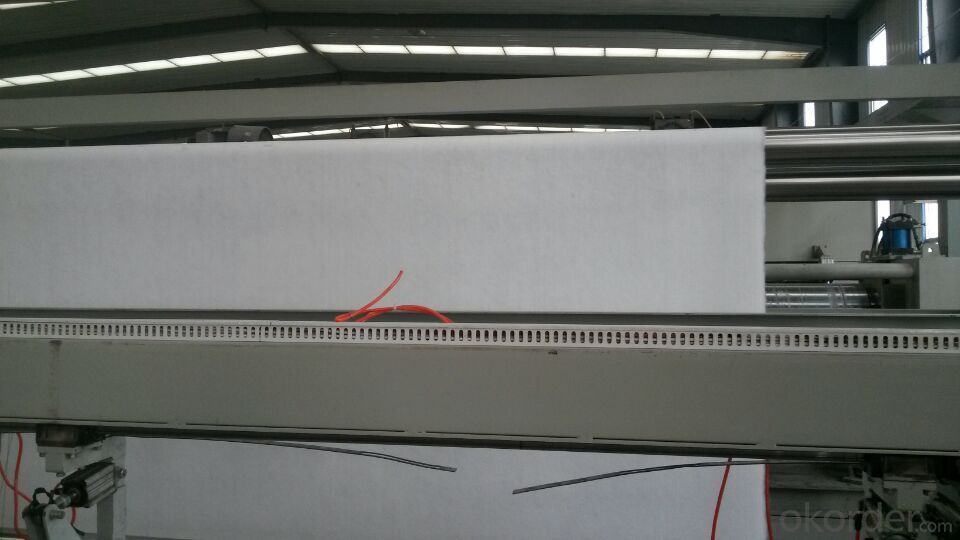

Type: | Geotextiles | Place of Origin: | Shan Dong , China (Mainland) | Brand Name: | CMAX woven geotextile |

Model Number: | High Strength | Geotextile Type: | Woven Geotextiles | Color: | White |

Strength: | 200/50KN/M | Elongation: | <15%< span=""> | Width: | 3.6m |

Roll length: | 200m |

Packaging & Delivery

Packaging Details: | Woven geotextile package:Rolled with cardboard core, wrapped with PE film and PP tape fabric |

Delivery Detail: | one 40'HQcontainer within 15 working days |

Specifications

our woven geotextile have superior properties for filtration, separation, reinforcement, erosion control

1.About Us

Company Profile :

We have more than 25 years experience in development & manufacture synthetics like woven geotextile , geotube,silt curtain,concrete filling mattress,pile jacket and industrial

fabric. Depending on our full set production line, well equipped laboratory, cooperation with

institute& college and experienced employees, we havesuccessfully developed and

consolidated domestic and foreign market.

Metric and British conversions:

1kn/m------around68.57lbs/ft 1oz/yd2---around 33.9g/m2 1m------around 3.3ft

Physical properties | Test method | Unit | Typical Value | ||||||||||

Material | Polypropylene/PP | ||||||||||||

Unit Weight | ASTM D 5261 | g/m2 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1300 | ||

Color | White | ||||||||||||

Tensile Strength at break MD | ASTM D 4595 | KN/M >= | 50 | 75 | 100 | 130 | 160 | 180 | 200 | 230 | 360 | ||

Tensile Strength at break CD | ASTM D 4595 | KN/M >= | 35 | 52 | 70 | 90 | 112 | 126 | 140 | 160 | 280 | ||

Elongation at break MD | ASTM D 4595 | % <=< span=""> | 35 | 35 | 35 | 35 | 35 | 35 | 35 | 35 | 35 | ||

Elongation at break CD | ASTM D 4595 | % <=< span=""> | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | ||

CBR Puncture Strength | ASTM D 6241 | KN | 4 | 6.9 | 10.5 | 14 | 18 | 20.5 | 23 | 24 | 28 | ||

Tear Strength | ASTM D 4533 | KN | 0.6 | 1 | 1.3 | 1.55 | 1.9 | 2 | 2.2 | 2.3 | 3.2 | ||

Permitivity | ASTM D 4491 | S-1 | 0.01-0.8 | ||||||||||

Pore opening size O90 | ASTM D 4751 | mm | 0.06-0.7 | ||||||||||

Width: max 3.8m, standard 3.6m. Other colors available. | |||||||||||||

Physical properties | Test method | Unit | Typical Value | |||||||

Material | Polyester/PET | |||||||||

Color | White | |||||||||

Tensile Strength at break MD | ASTM D 4595 | KN/M | 100 | 150 | 150 | 200 | 400 | 300 | 500 | 1000 |

Tensile Strength at break CD | ASTM D 4595 | KN/M | 50 | 50 | 150 | 50 | 50 | 300 | 100 | 50 |

Elongation at break MD | ASTM D 4595 | % | <=15< span=""> | |||||||

Elongation at break CD | ASTM D 4595 | % | <=15< span=""> | |||||||

Permitivity | ASTM D 4491 | S-1 | 0.01-0.8 | |||||||

Pore opening size O90 | ASTM D 4751 | mm | 0.06-0.7

| |||||||

FAQ

1. Can you send samples to us ?

Yes , free samples could be provided , but customer need pay for the freight cost .

After order placed , the freight charge could be refund .

2. What’s your Payment term ?

T/T , L/C , Western Union,Paypal

3. What’s your delivery method ?

By sea , By train , etc

4. What's your MOQ quantity ?

MOQ is one 20'container , the quantity could be negotiable

- Q: How do geotextiles improve the performance of geosynthetic clay liners?

- Geotextiles improve the performance of geosynthetic clay liners by acting as a cushioning layer, preventing the direct contact between the clay liner and the surrounding soil, which helps to reduce the risk of puncture or damage to the liner. Additionally, geotextiles enhance the drainage capabilities of the clay liner by allowing water to pass through while retaining the clay particles, which improves the liner's hydraulic conductivity and overall performance in terms of filtration and containment.

- Q: Can geotextiles be used in underground gas storage projects?

- Yes, geotextiles can be used in underground gas storage projects. Geotextiles are often used as a lining material in gas storage projects to provide separation, filtration, and reinforcement. They help to prevent the migration of soil particles, maintain the integrity of the storage structure, and ensure the overall stability of the project.

- Q: How do geotextiles affect soil compaction?

- Geotextiles can help reduce soil compaction by providing a porous layer that allows for better water infiltration and air circulation. This prevents the soil from becoming compacted and allows it to maintain its natural structure and permeability.

- Q: What are the key considerations for geotextile installation in high-altitude regions?

- When installing geotextiles in high-altitude regions, there are several key considerations to keep in mind. Firstly, the extreme weather conditions typically found in high-altitude areas, such as low temperatures, strong winds, and heavy snowfall, can impact the installation process. Therefore, selecting geotextiles with high durability and resistance to these conditions is crucial. Secondly, proper site preparation becomes even more important in high-altitude regions. The ground should be thoroughly assessed for its stability and potential frost heaving. Adequate measures, such as ground stabilization techniques and proper drainage systems, should be employed to ensure the long-term effectiveness of the geotextile installation. Furthermore, the selection of suitable installation methods is crucial in these regions. The use of specialized equipment and techniques, such as anchoring systems or thermal bonding, may be necessary to counteract the harsh environmental conditions and ensure proper geotextile performance. Lastly, it is essential to consider the environmental impacts of the geotextile installation in high-altitude regions. This includes adhering to local regulations and best practices to minimize disturbance to sensitive ecosystems and wildlife habitats. Overall, key considerations for geotextile installation in high-altitude regions include selecting durable materials, conducting thorough site preparation, using suitable installation methods, and addressing environmental concerns.

- Q: What are the key factors affecting the filtration performance of geotextiles?

- The key factors affecting the filtration performance of geotextiles include the pore size and distribution of the fabric, the thickness and permeability of the material, the hydraulic gradient or pressure difference across the geotextile, and the presence of any clogging or blockage due to soil particles. Other factors such as the type of soil, the duration of filtration, and the geotextile's chemical and physical properties can also influence its performance.

- Q: Can geotextiles be used in riverbank stabilization applications?

- Yes, geotextiles can be used in riverbank stabilization applications. They are commonly used to prevent erosion and promote soil stability along riverbanks. Geotextiles have the ability to filter water while allowing for proper drainage, which helps to prevent soil erosion and maintain the integrity of riverbanks. They can be installed as a protective barrier and provide reinforcement to the soil, making them an effective solution for riverbank stabilization.

- Q: Composite geotextile plastic composite

- 1, plastic composite geotextile is woven with a woven fabric as the substrate, the extruded coated polyolefin resin film or polyolefin resin sandwich layer, the woven cloth and all kinds of Zhang made together. 2, the product made of bags with light weight, acid and alkali resistance, strength, moisture and other advantages. 3, widely used in chemical fertilizer, synthetic resin, coarse salt, ore and cement products such as packaging, is a good packaging of heavy packaging materials

- Q: Which big god has the relevant documents? bow down!

- Geotechnical materials in the application of seepage in the drainage, the specific is to protect the blind ditch.

- Q: What are the advantages of using geotextiles in shoreline stabilization?

- Geotextiles offer several advantages in shoreline stabilization. Firstly, they act as a barrier, preventing erosion caused by waves, tides, and currents. They effectively hold the soil in place, reducing the risk of land loss and maintaining the integrity of the shoreline. Secondly, geotextiles are permeable, allowing water to pass through while retaining the soil particles, which helps in maintaining a stable and balanced ecosystem. Additionally, they are durable and resistant to UV degradation, ensuring a long lifespan and reducing the need for frequent maintenance. Lastly, geotextiles are easy to install and cost-effective compared to traditional methods, making them a practical choice for shoreline stabilization projects. Overall, geotextiles provide a sustainable and efficient solution to protect and enhance coastal areas.

Send your message to us

Geotextile Fabric Staples Woven PP Earthwork for Road Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords