Geotextile Fabric Construction PP/PET Nonwoven Geotextile with Short Fiber

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Non Woven Geotextile with Short Fiber Needle Punched, Find Details about Non Woven Geotextile with Short Fiber Needle Punched and Make an Inquiry for Geotextile at OKorder.com.

Geotextile Specifications:

Geotextile fabrics

Material:polyester/polypropylene fibric

Width:1-9m

Colour:white or black

Use:road ,highway,filter

Weight:100-1500g/m2

Tensile strength:2.5KN/m-25KN/m

Break elogation:25-100%

Gextextile Description:

--Our geotextile can be made of polypropylene (PP) or polyester (PET) .

-- The weight is available from 100g/m2 to 1500g/m2 and the width from 1m to 8m,

-- Two kinds of processing technical to select: needle punched and thermally bonded, long fiber or short fiber.

-- All kinds of colors are available.

It is widely known as earthwork material and industry fabric, used in the areas of railway, highway, water conservancy, dam, tunnel, subway, environment protection and so on.

-- We can supply different specifications as customers’ request.

Geotextile Specification:

Material: polypropylene (PP) thermally bounded

Weight: 100g/m2-1500g/m2

Width: 1-9m

Length: As customers’ demand (usually is 100m)

Package: PE film and woven cloth

Delivery time: With in 3weeks after received the advance payment

Payment terms: T/T 30% in advance+T/T 70% against the copies of original documents or L/C

PS. Also we can produce the product as customer’s demand.

Application of Geotextile:

1. Filtration

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2. Separation

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3. Reinforcement

The highway, railway, soilstone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4. Protection

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

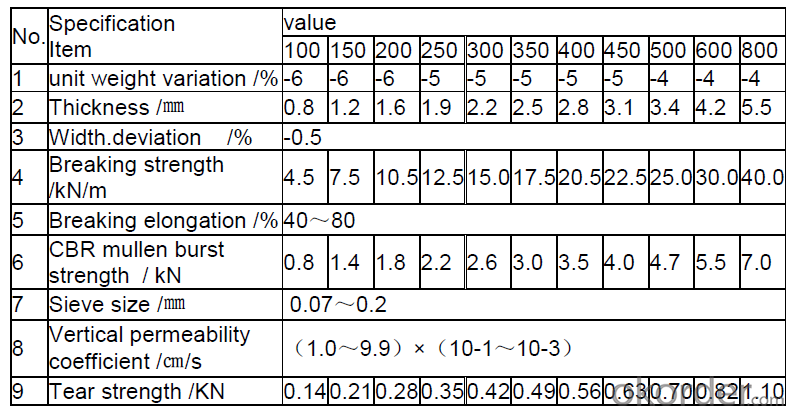

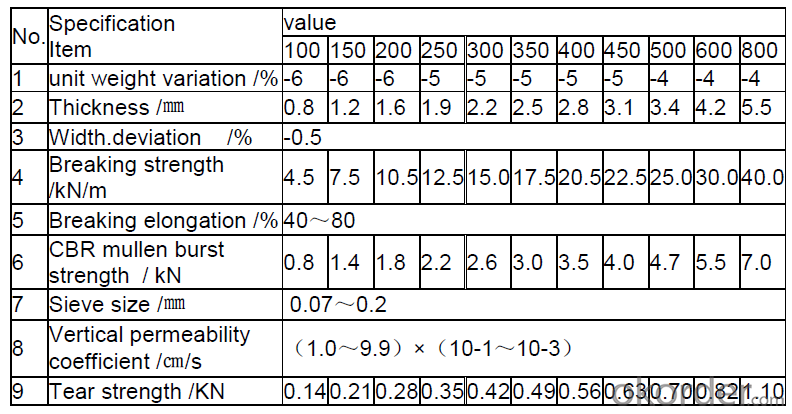

Technical specification of short fiber needle punched non-woven geotextiles:

According to GB/T17638-1998 Standard

Geotextile Specification

Geotextile Show:

Geotextile Show:

RFQ:

- Q: What can we do for the special customer?

A: Provide custom made service with customer's drawing; We make sure to provide you with the best solutions for your individual case. Whether standard items or non-standard items.

- Q: What can we supply?

A: We provide high levels of communication from start to finish.

- Q: What is our advantage?

A: Top Cemented Carbide has extensive business experience, Fast delivery and high quality.

If you want to find more details about the non-woven geotextile, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q: Is the filament geotextile the same as the tensile strength of other acupuncture nonwoven fabrics?

- 1, polyester filament acupuncture non-woven geotextile pet.15-6-300, is the national standard filament geotextile, the material for the polyester polyester (PET), the unit area of the quality of 300g / ㎡, the breaking strength of 15KN / m in line with GB GB / T-2008 standard 300g / ㎡ filament geotextile requirements. Polyester filament acupuncture non-woven geotextile pet.15-6-300 product width of 6m, 6m wide polyester filament geotextile is a more conventional products, manufacturers can directly produce 6m wide polyester filament Geotextile. 1. First geotextile polyester staple fiber geotextile (PET) and polyester filament geotextile two. The physical tensile strength of the two geotextiles is different. 2. Polyester staple geotextile according to the national standard GB / T-2008 standard implementation, 400g GB polyester staple geotextile physical tensile strength ≥ 12.5KN. 3. Polyester filament geotextile in accordance with the national standard GB / T-2008 standard implementation, 400g GB polyester filament geotextile physical tensile strength ≥ 20KN. 4.400g GB polyester staple geotextile longitudinal and horizontal tear strength ≥ 0.33KN, 400g GB polyester filament geotextile longitudinal and horizontal tear strength ≥ 0.56KN.

- Q: How do geotextiles contribute to the stability of landfill slopes?

- Geotextiles contribute to the stability of landfill slopes by providing reinforcement and erosion control. They are placed between different layers of soil to enhance the overall strength and stability of the slope. Geotextiles help to distribute the loads more evenly, preventing excessive settlement and potential slope failure. Additionally, they reduce soil erosion by acting as a barrier against water flow, thus protecting the slope from erosion and maintaining its stability over time.

- Q: How do geotextiles improve the performance of railway tracks?

- Geotextiles improve the performance of railway tracks by providing reinforcement and stabilization to the track bed, preventing soil erosion and reducing settlement. They also enhance drainage, reducing water accumulation and improving the overall resilience and durability of the tracks.

- Q: How do geotextiles prevent soil erosion on slopes?

- Geotextiles prevent soil erosion on slopes by providing a stable and protective layer that helps retain the soil in place. These synthetic materials are placed on the slope and act as a barrier, preventing the soil from being washed away by rainfall or runoff. Geotextiles also promote proper drainage, allowing excess water to flow through while retaining the soil particles. This helps to maintain the integrity of the slope and reduce erosion caused by water movement.

- Q: What are the design considerations for geotextile-reinforced soil walls?

- Some of the design considerations for geotextile-reinforced soil walls include the selection of appropriate geotextile material, determining the required strength and stability of the wall, evaluating the site conditions and soil properties, considering the drainage requirements, ensuring proper connection and anchorage of the geotextile to the wall, and considering any potential environmental factors that may affect the performance of the wall.

- Q: How do geotextiles help with soil separation in railway ballast systems?

- Geotextiles help with soil separation in railway ballast systems by preventing the mixing of different layers and ensuring the stability of the ballast. They act as a barrier between the ballast and subgrade, preventing the migration of fines from the subgrade into the ballast layer. This separation helps maintain the structural integrity of the railway track, reducing the risk of settlement and track deformations. Geotextiles also enhance drainage by allowing water to flow freely through the ballast layer, preventing waterlogging and maintaining the overall stability of the track.

- Q: Geotextile strength index with interpolation method how to calculate? Then geotextile variation, I do not quite understand, pro, if you know whether to tell me Oh! Very anxious

- Geotextile strong indicators of the interpolation method: For example: geotextile 150 grams of breaking strength is 4.5KN, geotextile 100 grams of breaking strength is 2.5KN, then the geotextile 130 grams of broken strength is how much? The calculation method is: 4.5KN-2.5KN = 2KN (that is, 50 grams of geotextile strength) 2KN by 50 grams multiplied by 30 grams is equal to 1.2KN then geotextile 130 grams of breaking strength is 3.7KN.

- Q: Can geotextiles be used in subgrade stabilization?

- Yes, geotextiles can be used in subgrade stabilization. They are often used to improve the stability and strength of the subgrade by reducing soil erosion, providing drainage, and enhancing load distribution. Geotextiles can help prevent the mixing of subgrade soil with the overlying base materials, thus reducing the potential for settlement and deformation.

- Q: Are geotextiles resistant to hydrolysis?

- Yes, geotextiles are generally resistant to hydrolysis.

- Q: How do geotextiles improve the stability of slopes?

- Geotextiles improve the stability of slopes by providing reinforcement and erosion control. They are placed within the slope to enhance its strength, prevent soil erosion, and increase overall stability. The geotextiles act as a barrier, distributing the forces exerted on the slope and reducing the potential for sliding or failure. Additionally, they can promote water drainage, preventing the accumulation of excess water that may weaken the slope. Overall, geotextiles play a crucial role in enhancing the stability and longevity of slopes.

Send your message to us

Geotextile Fabric Construction PP/PET Nonwoven Geotextile with Short Fiber

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords