Prime Geotextile Continuous Filament Spunbonded Nonwoven Style

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Continuous Filament Spunbonded Nonwoven Geotextile

Introdcution of Continuous Filament Spunbonded Nonwoven Geotextile:

Made from virgin PET (polyester) chips, the continuous filament was extruded from PET chip by machine directly by spunbond process, and then punch together to get the stable 3D with higher strength fabric. So it has high strength, good creep property excellent and erosion resistance, aging-resistance and heat resistance.

Specifications of Continuous Filament Spunbonded Nonwoven Geotextile:

•100g/m2—800g/ m2

•4m—7m in roll width

the length as clients’ request

Production Standard:

GB/T17638-1998

Jt/t 520-2004

Advantage of Continuous Filament Spunbonded Nonwoven Geotextile:

Good creep property and hydraulics property, resistance to corrosion, excellent anti-aging and heat-resistance quality.

Applications of Continuous Filament Spunbonded Nonwoven Geotextile:

• Filtration of soils in drainage applications by retaining soil particles while allowing for the free flow of water.

•Separation and stabilization in road and railway construction

•Prevention of soil movement in erosion control measures

•Cushioning and protection in many containment projects

FAQ:

1. Which payment do you accept?

For you convinience,our payment can be L/C,TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world.

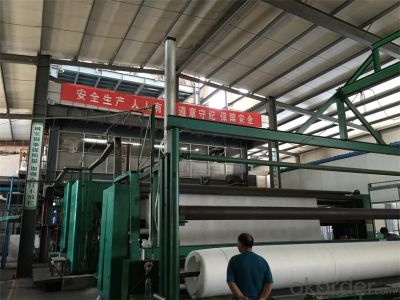

Photos of Products and Factory:

- Q: How do geotextiles help with subgrade stabilization?

- Geotextiles help with subgrade stabilization by providing a strong, flexible, and permeable layer that separates the subgrade soil from the overlying layers. This prevents the mixing of different soil layers, increases the load-bearing capacity of the subgrade, reduces settlement and deformation, and improves overall stability and performance of the pavement or structure.

- Q: Can geotextiles be used for erosion control in riverbanks?

- Yes, geotextiles can be used for erosion control in riverbanks. Geotextiles are permeable fabrics that can be installed along riverbanks to stabilize the soil and prevent erosion by filtering water, reducing water velocity, and promoting vegetation growth. They provide a cost-effective and environmentally friendly solution for erosion control in riverbanks.

- Q: Geotextile geotextile geotextile construction geotextile specific application

- Geotextile in the construction of the main building is to protect the concrete: 1, in the summer construction of geotextile is to protect the concrete in the water; 2, in the winter construction of geotextile that can protect the concrete moisture also play a role in insulation.

- Q: Geotextile cloth how many square feet

- Geotextile laying - including the labor costs (according to geotextile specifications and laying conditions and requirements are different), material costs (specific quality requirements and thickness, are not the same ..), mechanical use costs (such as transport, sewing System, hoisting, etc.). The price is different. Sometimes the construction of our geotextile laying, the price per square meter from 9 yuan to 50 yuan range.

- Q: How do geotextiles help with filtration in wastewater treatment systems?

- Geotextiles help with filtration in wastewater treatment systems by acting as a barrier that separates the liquid from the solid particles. They allow the water to pass through while trapping and retaining the suspended solids, sediments, and other pollutants. This enhances the treatment process by improving the efficiency of filtration and preventing clogging or blockages in the system.

- Q: How do geotextiles aid in the reduction of soil settlement?

- Geotextiles aid in the reduction of soil settlement by providing a separation layer between two soil layers, preventing intermixing and consolidation. This separation minimizes the migration of fine particles and water, maintaining the stability and integrity of the soil layers, ultimately reducing settlement.

- Q: Can geotextiles be used for reinforcement of railway embankments?

- Yes, geotextiles can be used for reinforcement of railway embankments. Geotextiles are often used in civil engineering projects to improve the stability and performance of soil structures. In the case of railway embankments, geotextiles can be placed beneath the ballast layer to enhance the load-bearing capacity of the soil, prevent erosion, and improve overall embankment stability.

- Q: What kind of geotextile is used to repair the road?

- Call one three seven to understand three one two one two to ensure that the quality of price satisfaction

- Q: Composite waterproof board, is the waterproof board and geotextile stick together call it?

- Yes. Now there are mainly adhesive technology, thermal composite process, Laminating process.

- Q: Are geotextiles resistant to fungal growth?

- Yes, geotextiles are generally resistant to fungal growth due to their synthetic nature and the materials they are made from.

Send your message to us

Prime Geotextile Continuous Filament Spunbonded Nonwoven Style

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords