GB Q235 Cr Steel Billets China Manufacture

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Product Description

GB Q235 Steel Billets

| Product Name | Steel Billets |

| Size | 60×60mm, 100×100mm, 120×120mm, 130×130mm, 150×150mm |

| Length | 6M, 9M, 12M |

| Grade | Q235 |

| Standard | GB |

| Chemical Composition | Q235: C: 0.14-0.22% MN: 0.3-0.7% SI: 0.3% max P: 0.045%max S: 0.045%max |

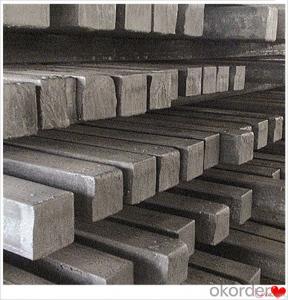

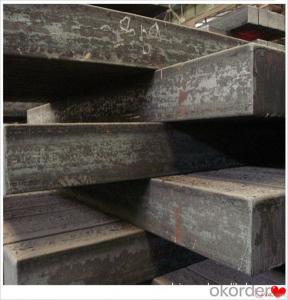

2. Product Picture

3. FAQ

1. Q: How can I visit there?

A: Our company is located in China. Welcome to visit us.

2. Q: Can I get sample and how long will it take?

A:Yes. We can supply sample. And you need to pay for courier.

3. Q: What's the MOQ?

A: Our MOQ is 25mt.

4. Q: What's the delivery time?

A: It will take about 30 days after TT or L/C.

5. Q: What is the payment terms?

A: T/T, L/C at sight

6. Q: How does your factory carry out quality control?

A: We attach great importance to quality control.Every part of our products has its own QC.

7. Q: What certificate do you have?

A: We have SGS, ISO9001 etc. Also we can apply any certificate if you need if the qty is OK.

4. Shipment:

Logistic department established and serves for sales department. Cargo is delivered to the port by our own trucks. Both bulk and container service are available and cargo shipment is in hands of logistic staffs.

- Q: What are the properties of stainless steel for medical applications?

- Stainless steel used in medical applications is known for its exceptional properties such as corrosion resistance, high strength, durability, and biocompatibility. These properties make it an ideal material for surgical instruments, implants, and medical devices. Additionally, stainless steel can be easily sterilized, has good formability, and allows for precise manufacturing, making it a reliable choice in the medical field.

- Q: How is steel used in the production of medical devices and equipment?

- Steel is used in the production of medical devices and equipment due to its exceptional strength, durability, and corrosion resistance properties. It is commonly used to manufacture surgical instruments, implants, prosthetics, and various surgical and diagnostic equipment. The high strength of steel allows for precise and reliable performance, while its resistance to corrosion ensures longevity and sterility of medical tools in demanding healthcare environments.

- Q: How are steel products used in the construction of airports and terminals?

- Steel products are commonly used in the construction of airports and terminals due to their strength, durability, and versatility. They are used to create structures such as hangars, terminal buildings, and control towers, as well as for supporting infrastructure like runways, bridges, and walkways. Steel is also used for manufacturing doors, windows, and security systems, ensuring the safety and functionality of these facilities. Additionally, steel is employed in the construction of luggage handling systems, escalators, and elevators, enhancing the efficiency and convenience of airports and terminals.

- Q: How is steel bar reinforcement used in concrete structures?

- Steel bar reinforcement is used in concrete structures to enhance their strength and durability. It is typically placed within the concrete to resist tensile forces and prevent cracking. The steel bars, also known as rebars, provide additional support and ensure that the concrete structure can withstand heavy loads and external pressures.

- Q: How is steel used in the production of electrical appliances and wiring?

- Steel is commonly used in the production of electrical appliances and wiring as it provides a strong and durable framework for various components. It is often used in the construction of appliance casings, motor housings, and brackets, ensuring the safety and protection of internal electrical components. Additionally, steel is used in electrical wiring as a support structure, providing strength and stability to carry and distribute electricity effectively.

- Q: How are steel products used in the aerospace industry?

- Steel products are used in the aerospace industry for various applications, such as structural components, engine parts, landing gears, and fasteners. Steel's high strength-to-weight ratio, durability, and resistance to high temperatures make it an ideal material for ensuring the safety, reliability, and performance of aircraft.

- Q: What is the impact of steel production on the environment?

- Steel production has a significant impact on the environment due to its resource-intensive nature and high carbon emissions. The extraction of raw materials, such as iron ore and coal, leads to habitat destruction and air and water pollution. The traditional blast furnace method emits a substantial amount of greenhouse gases, contributing to climate change. Additionally, the production process generates waste, including slag and emissions of toxic substances. However, advancements in technology, such as recycling and cleaner production methods, offer potential solutions to mitigate these environmental impacts.

- Q: How do steel products contribute to the construction of research laboratories and scientific facilities?

- Steel products play a crucial role in the construction of research laboratories and scientific facilities. They provide structural support and durability, ensuring the safety and integrity of the buildings. Steel beams, columns, and frames are commonly used to create large open spaces, allowing for flexible layouts and accommodating various equipment and machinery. Additionally, steel is resistant to fire, corrosion, and pests, making it an ideal choice for laboratories where hazardous materials and sensitive experiments are conducted. Overall, steel products are essential components in creating efficient, functional, and secure research facilities.

- Q: How is steel used in the production of playground equipment?

- Steel is commonly used in the production of playground equipment due to its strength, durability, and ability to withstand outdoor elements. It is used to construct the frames, supports, and chains of various play structures such as swings, slides, and climbing frames. Steel's robust nature ensures the equipment can safely support the weight of children and withstand frequent use and harsh weather conditions, making it an ideal material for playground equipment.

- Q: How is steel tubing used in the oil and gas industry?

- Steel tubing is commonly used in the oil and gas industry for various applications such as drilling, production, and transportation. It is used in wellbore completion operations to extract oil and gas from the reservoirs. Additionally, steel tubing is utilized for the construction of pipelines, providing a durable and efficient means of transporting oil and gas over long distances. The strength and corrosion resistance of steel tubing make it an ideal choice for these demanding industry requirements.

Send your message to us

GB Q235 Cr Steel Billets China Manufacture

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords