Chrome Price Q235 CNBM Steel Billets with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

| GRADE | SIZE | APPLICATION |

| Q235 | 100mm*100mm*6m | REBAR |

| 120mm*120mm*6m | ||

| 130mm*130mm*6m/12m | ||

| 150mm*150mm*6m/12m |

Chemical Compositon

| Q235 | C (%) | Si (%) | Mn (%) | P(%) | S(%) |

| 0.14-0.22 | 0.15-0.30 | 0.40-0.65 | 0.040% Max | 0.05Max |

Company Information:

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

Packing & Delivery

1. Packaging: seaworthy package or as required

2. Delivery: 35-45 days or based on quantity

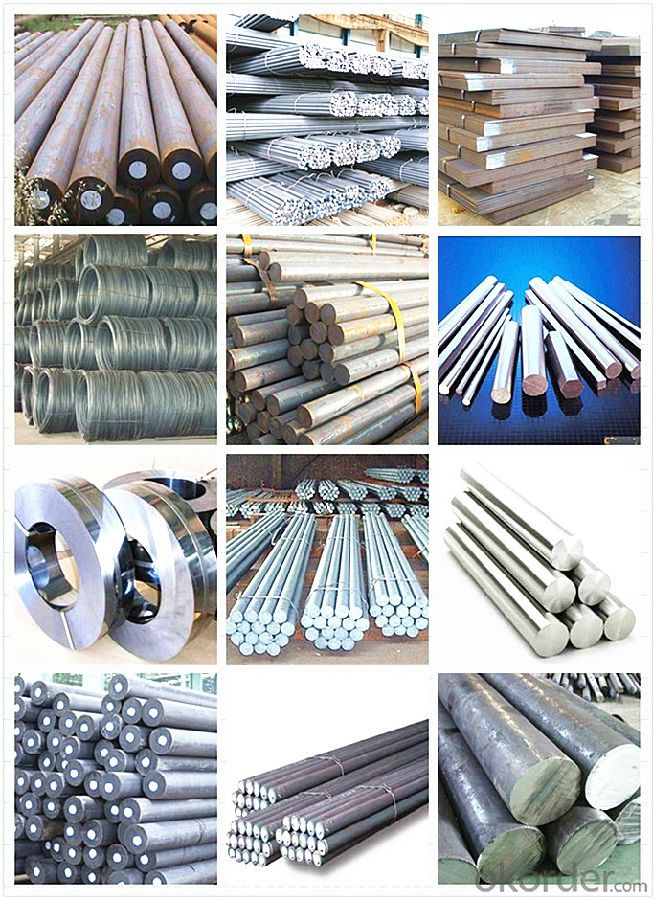

Products Show

Workshop

FAQ:

1.Your advantages?

Professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent

customer solution proposale

2. Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3. Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department

of these factories. Also CNBM is the holding company of many factories.

4. Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5. Trading Terms?

EXW, FOB, CIF, FFR, CNF

6. After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business

partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: How does special steel contribute to the impact resistance of products?

- Special steel, also known as high-strength or high-performance steel, plays a crucial role in enhancing the impact resistance of various products. This type of steel is specifically designed to possess exceptional strength, toughness, and durability, making it highly resistant to deformation and fracture under high-stress conditions. One of the key factors that contribute to the impact resistance of special steel is its composition. Special steel often contains alloying elements such as manganese, chromium, nickel, molybdenum, and vanadium, which are incorporated to enhance its mechanical properties. These alloying elements provide the steel with increased hardness, tensile strength, and resistance to wear, corrosion, and fatigue. As a result, products made from special steel are capable of withstanding heavy impact loads without deforming or breaking. Furthermore, the microstructure of special steel plays a vital role in its impact resistance. Through advanced manufacturing techniques, the steel's microstructure can be fine-tuned to achieve a desirable combination of strength and toughness. Special heat treatment processes, such as quenching and tempering, can further refine the microstructure, resulting in a material that can absorb and dissipate energy more effectively. This makes special steel highly resistant to cracks and fractures, even when subjected to sudden and severe impacts. In addition to its intrinsic properties, special steel is often used in the form of engineered components or structures that are specifically designed for impact resistance. For example, in the automotive industry, special steel is utilized for manufacturing components like crash beams, bumpers, and roll cages. These components are designed to absorb and distribute impact energy, protecting the vehicle and its occupants during accidents. Overall, special steel significantly contributes to the impact resistance of products by providing superior strength, toughness, and durability. Its unique composition, microstructure, and design enable it to withstand high-stress conditions and absorb impact energy effectively. As a result, products made from special steel offer enhanced safety and reliability, making them suitable for a wide range of applications in industries such as automotive, aerospace, construction, and defense.

- Q: Can special steel be used in the transportation industry?

- Yes, special steel can be used in the transportation industry. Special steel alloys, such as stainless steel and high-strength steel, offer superior strength, corrosion resistance, and durability, making them suitable for various applications in transportation. These steels are commonly used in the production of automotive components, aircraft parts, railway infrastructure, and ships, enhancing safety and performance in the transportation sector.

- Q: Can special steel be used in the manufacturing of tools?

- Yes, special steel can be used in the manufacturing of tools. Special steel, also known as alloy steel, is specifically designed to have enhanced properties such as high strength, hardness, and resistance to wear and corrosion. These characteristics make it an ideal material for the production of durable and high-performance tools used in various industries, including automotive, construction, and machinery.

- Q: How does special steel withstand high-velocity impacts?

- Special steel is able to withstand high-velocity impacts due to its unique properties and composition. One key factor is its high strength and hardness, which allows it to resist deformation and fracture under extreme forces. Special steel also often contains alloying elements such as chromium, molybdenum, nickel, and vanadium, which contribute to its exceptional toughness and impact resistance. Furthermore, special steel is often heat-treated to enhance its mechanical properties. Through processes such as quenching and tempering, the steel's microstructure is altered, resulting in a fine-grained structure with improved strength and hardness. This heat treatment also enhances the steel's ability to absorb and dissipate energy during high-velocity impacts, reducing the risk of failure. Moreover, special steel is often designed with specific alloys and compositions to enhance its performance in particular applications. For example, some grades of steel are specifically engineered for armor applications, where they must withstand high-velocity impacts from projectiles. These steels may have additional elements such as boron or titanium, which further enhance their ability to resist penetration and deformation under extreme loads. In summary, special steel's ability to withstand high-velocity impacts is attributed to its high strength, hardness, toughness, and impact resistance. Its unique composition, heat treatment processes, and targeted design make it a reliable choice for applications where impact resistance is crucial.

- Q: How is corrosion-resistant stainless steel used in the production of marine equipment?

- Corrosion-resistant stainless steel is extensively used in the production of marine equipment due to its ability to withstand the harsh and corrosive marine environment. It is commonly utilized in the construction of ship hulls, propellers, valves, pumps, and various other components that are constantly exposed to saltwater and other corrosive elements. The stainless steel's resistance to corrosion helps to ensure the longevity and reliability of marine equipment, reducing maintenance and replacement costs, and contributing to the overall safety and efficiency of maritime operations.

- Q: How does special steel contribute to improving product resistance to environmental factors?

- Special steel contributes to improving product resistance to environmental factors in several ways. Firstly, special steel alloys often have enhanced corrosion resistance, protecting the product from damage caused by exposure to moisture, chemicals, and other corrosive substances present in the environment. Additionally, special steel can offer improved strength and durability, enabling the product to withstand harsh conditions such as extreme temperatures, high pressure, or mechanical stress. Furthermore, special steel can exhibit excellent fatigue resistance, ensuring that the product maintains its structural integrity even after prolonged exposure to cyclic loading or repetitive stress. Overall, the unique characteristics of special steel make it a valuable material for enhancing the resistance of products to various environmental factors, ultimately prolonging their lifespan and reducing maintenance costs.

- Q: How is special steel used in the manufacturing of tools and dies?

- Special steel is widely used in the manufacturing of tools and dies due to its exceptional properties that make it suitable for these applications. Special steel, also known as tool steel, is specifically designed to have high hardness, wear resistance, toughness, and heat resistance. In the manufacturing of tools, such as drills, saws, hammers, and chisels, special steel is used to ensure durability and long tool life. The high hardness of special steel allows these tools to withstand the rigors of cutting, drilling, and shaping without easily dulling or deforming. Additionally, the wear resistance of special steel ensures that these tools can maintain their sharp cutting edges for an extended period, reducing the need for frequent sharpening or replacement. Moreover, in the production of dies used in various manufacturing processes, special steel plays a crucial role. Dies are used to shape materials into specific forms or sizes, such as in forging, stamping, or extrusion processes. The high toughness of special steel allows dies to withstand the high pressure and impact forces involved in these processes without cracking or fracturing. Additionally, the heat resistance of special steel ensures that dies can withstand the elevated temperatures generated during these operations without losing their shape or hardness. Special steel also offers excellent machinability, allowing it to be easily shaped and formed into complex tool and die designs. This property is significant in manufacturing, as it enables the production of intricate and precise tools and dies, leading to improved product quality and efficiency. Overall, special steel is an essential material in the manufacturing of tools and dies due to its exceptional hardness, wear resistance, toughness, heat resistance, and machinability. These properties ensure the durability, long tool life, and high performance of tools and dies, contributing to the overall efficiency and quality of various manufacturing processes.

- Q: What industries use special steel?

- Special steel plays a vital role in multiple industries, relying on its unique properties to carry out their operations. The automotive industry, for instance, utilizes special steel extensively in manufacturing engine parts, transmission systems, and chassis components. The exceptional strength, durability, and corrosion resistance of special steel make it an ideal choice for withstanding the challenging conditions faced by automotive components. Similarly, the aerospace industry heavily relies on special steel in constructing aircraft structures, engine components, and landing gear systems. The lightweight yet robust characteristics of special steel are crucial in ensuring the safety and performance of aircraft. In the energy sector, special steel is essential for producing equipment used in oil and gas exploration, such as drilling rigs, pipelines, and offshore platforms. The high-strength and corrosion-resistant properties of special steel enable it to withstand the harsh operating conditions prevalent in this industry. The construction industry is also a significant consumer of special steel, using it in the manufacturing of structural components, reinforcing bars, and precast concrete products. Special steel provides the necessary strength and durability required for building structures capable of withstanding diverse environmental conditions and heavy loads. Moreover, the manufacturing and machinery industry relies on special steel for producing heavy machinery, industrial equipment, and machine tools. The exceptional strength, wear resistance, and heat resistance properties of special steel make it well-suited to meet the demanding requirements of these applications. Lastly, the defense and military industry heavily depends on special steel for producing military vehicles, weapons, and armor. Special steel's ability to withstand extreme conditions and provide protection makes it a critical material in this industry. Overall, special steel's exceptional properties of strength, durability, corrosion resistance, and heat resistance make it indispensable across various industries. Its applications span from automotive and aerospace to energy, construction, manufacturing, and defense sectors, where reliability and performance are of paramount importance.

- Q: How is die steel used in metal stamping processes?

- Die steel is commonly used in metal stamping processes due to its high strength, hardness, and wear resistance properties. It is used to create dies, which are specialized tools that shape and cut metal sheets or strips into desired shapes. Die steel ensures that the dies can withstand the high forces and repetitive actions involved in metal stamping, allowing for precise and efficient production of various metal components and products.

- Q: How does special steel contribute to the railway industry?

- Special steel plays a crucial role in the railway industry by contributing to the development and maintenance of efficient and reliable rail systems. The unique properties of special steel, such as high strength, durability, and resistance to wear and tear, make it an ideal material for various components and structures within the railway infrastructure. One of the key areas where special steel contributes to the railway industry is in the manufacturing of rails. Special steel rails are designed to withstand heavy loads and intense usage, ensuring the safe and smooth movement of trains. These rails are highly resistant to wear, fatigue, and deformation, resulting in longer service life and reduced maintenance costs. Additionally, special steel is used in the manufacturing of wheelsets, which are critical components of trains. The high strength and durability of special steel make it ideal for wheelset production, ensuring reliable performance and minimizing the risk of derailments. The use of special steel in wheelsets also contributes to increased operational efficiency, as it reduces friction and enhances energy transmission, leading to improved fuel economy and reduced environmental impact. Furthermore, special steel is utilized in the construction of bridges, tunnels, and other infrastructure elements within the railway network. These structures must withstand heavy loads, extreme weather conditions, and various environmental factors. Special steel's exceptional strength, corrosion resistance, and longevity make it a preferred choice for such applications, ensuring the safety and reliability of rail systems. In summary, special steel significantly contributes to the railway industry by providing the necessary strength, durability, and resistance to wear and tear for various components and structures. Its use in rails, wheelsets, and infrastructure elements enhances the efficiency, reliability, and safety of rail systems, ultimately benefiting passengers, freight transport, and the overall transportation sector.

Send your message to us

Chrome Price Q235 CNBM Steel Billets with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords