GASS Lightweight Aluminum Slab Formwork Unique Locking Ledger Frames for Building

- Loading Port:

- Shekou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 8000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Pictures of GASS Lightweight Aluminum Slab Formwork

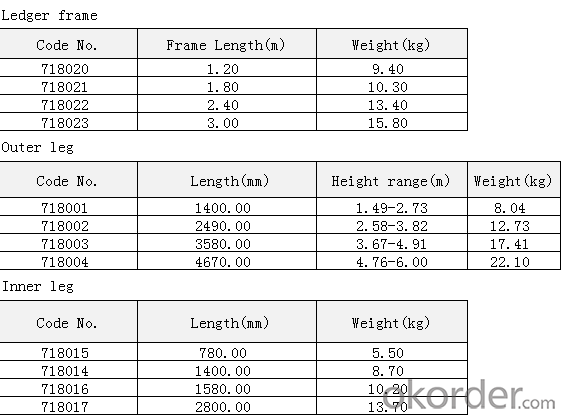

Specification of GASS Lightweight Aluminum Slab Formwork:

Benefits of the ledge frame:

※ Only four wedge connections per frame result in fast installation

※ Clearly visible wedge results in easy identification

that ledger frame is safety and correctly installed.

※ Ledger frame can be removed from an erected structure

to enable personnel and material access.

※ Ledger frames in four sizes offer the user versatility

with a minimum number of componens.

※ When utilising access platforms,top rung of ledger frame provides a secure handrail.

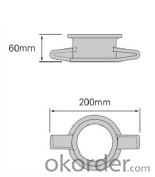

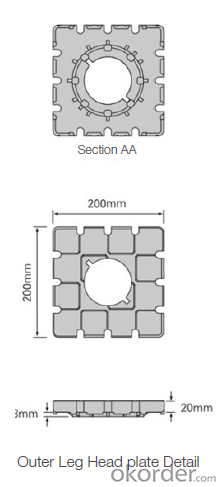

Benefits of the outer leg:

※ Eight slot profile allows versatility for attachment of ledge frames in multiple directions.

※ No loose parts.

※ Interlocking head plate eliminates eccentricity.

※ Raised "lip"on head ensures that bolted fixings,leg to leg and leg to beam are easily located and secured eliminating eccentricity.

※ Sprung latch design enables inner leg to be secured safely every time.

※ Eight point profile provides high rigidity to inner leg.

Benefits of the inner leg:

※ Provides up to 1314mm extension with the standard length inner leg (1680mm)2200mm extension with the special length inner leg.

※ Interlocking base plate eliminates eccentricity.

※ Dry-coated thread requires no additional lubricant.

※ Cast collar for optimum strength.

※ Removable grub screw to prevent over extension and to allow for collar replacement.

- Q: What are the mixing arms of the concrete mixer?

- Mixing arm concrete mixer is a component of the mixing arm itself and divided into lateral mixing arm (positive and negative points), stirring arm (also have positive and negative points), stirring arm below is the bearing seat connected, connected with 4 sets of high strength bolts with stirring arm. The top is equipped with wear-resistant mixing blades, connecting with mixing blades, high-strength bolts 2 sets. In addition, some manufacturers have designed mixing side bonded shaft swivel, is installed in the interval between the stirring arm fixed and rotated in two ways.

- Q: What are the details of construction machinery parts in sand casting?

- (3) equipped with fittings, installation type air switch and air shower room installed in the furnace. (2) all kinds of vehicle tracks, transmitters, differential pressure and buttons are all materials other than the equipment body. (3) rotating filter network circulating water system for equipment, induction phase shifter, manhole and other various products embedded parts, clean bench, meter, scientific research and other functions of the machine, and pipeline safety device, railing, peep hole, ventilation air heater (1):

- Q: What measures can effectively reduce the construction accident rate?

- Hefei construction workers training _ eliminate dangerous source: eliminate the risk source of the system can fundamentally prevent accidents. But an important point of system safety is that it is impossible to completely eliminate all sources of danger and that people can only selectively eliminate several specific sources of danger. Generally speaking, when the risk of a dangerous source is higher, we should first consider whether we can take measures to eliminate it. A dangerous source can be completely eliminated by selecting the proper production process, technology, equipment, reasonable design, structural form or suitable raw material. For example: instead of the power system with pneumatic or hydraulic system, to prevent the occurrence of electrical accidents; instead of compressed air system for hydraulic system, to avoid the pressure vessel, pipeline rupture caused by shock wave; with incombustible materials instead of combustible materials, to prevent the occurrence of fire. It should be noted that sometimes measures are taken to eliminate certain sources of danger, but new sources of danger may be brought about. For example, an electric pneumatic system instead of a power system can prevent electrical accidents, but a physical explosion accident may occur in the compressed air system.

- Q: Building materials, equipment, components and fittings products must have "three certificates" is what cards?

- Product quality certification, also known as product certification, internationally known as qualified certification. According to the 1991 implementation of the "people's Republic of China Quality Certification Management Regulations", the product quality certification is based on the product standard and relevant technical requirements, the certification institution confirmed by the certification and certification marks to prove that a particular product is in conformity with the relevant standards and technical requirements of the corresponding activities.

- Q: Definition of large mechanical equipment?

- Depending on the size of the part to be machined, the parts must be set up as large equipment with the aid of a crane, and large machinery is usually assembled after the parts have been delivered to the destination. Material handling machinery is mainly in enterprises (including terminals, materials, mines and commercial warehouses, etc.) within the material handling, transportation, lifting, stacking and storage of machinery and equipment

- Q: What kind of electrical equipment do you have? What are the main components of each device?

- 1 、 electrical equipment part of electrical equipment mainly refers to: substation and distribution of power equipment and local scattered power, lighting distribution box. Such as: dry type power transformer, high voltage and low voltage power distribution cabinet, control the use of DC cabinet (with battery), standby uninterruptible power supply cabinet, lighting distribution box, power distribution box (cabinet), power factor capacitor compensation cabinet and standby diesel generator etc.. The utility model is characterized in that the rated voltage is mostly 10KV380V/220V by the combination of independent functional electric components, and the voltage is only 24V or 12V in the control system only.

- Q: How do the welding parts in the welding drawings of the machine parts indicate the technical requirements of the drawings?

- Therefore, the medium carbon steel has the most extensive application in the medium strength level. Besides being used as building material, it is widely used in the manufacture of various mechanical parts. Welding: 1 the preheating is conducive to reducing carbon steel heat affected zone is the most

- Q: Construction machinery production need to deal with what documents?

- Construction machinery production needs for documents are: first, the construction enterprise safety production license application form 1, form three copies; 2, fill in the application form for details of the "instructions" application form "; 3, the legal representative of the enterprise statement" column should be the legal representative signature, enterprise official seal;

- Q: Where are the hanging baskets for the building?

- It is forbidden to take a stool or put a ladder on a hanging basket to work higher; it is not allowed to work alone in a basket, and no electric machinery or equipment can be placed in the basket;

- Q: What functions should be achieved in mechanical structure design?

- The function of the mechanical structure is mainly realized by the geometry of the machine parts and the relative position between the parts. The geometry of a part is made up of its surface, and a part usually has a number of surfaces, some of which are in direct contact with the surface of other parts, and this part of the surface is referred to as the functional surface. The connecting part between the functional surfaces is called the join surface

Send your message to us

GASS Lightweight Aluminum Slab Formwork Unique Locking Ledger Frames for Building

- Loading Port:

- Shekou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 8000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords