Galvanized Stel coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Specification:

Thickness: 0.2-3.0mm

Width: 600-1500mm

Coating Mass: Z08,Z12,Z18,Z20,Z22,Z25,Z27,Z35

Z80,Z120,Z180,Z200,Z220,Z250,Z275

Tolerance for thickness,width,flatness and so on conform to the requirements of JIS G3302 or ASTM A653M/924M

Coil ID can be either 508mm or 610mm, maximum coil OD is 2000mm

The speicfication of ASTM Such as A653m,A924 M and so on have been updated to the latest revisions

Application:

BUILDING & CONSTRUCTION

Floor decks, ceilings, verandas, rolling doors, warehouse, partitions, sheds, gutters, wall, underground piping, sashes, beams, fences, scaffolding, indoor decorations, ducts, ventilating pipes, steel frames and cable trays.

ELECTRICAL APPLIANCES

Freezers, video recorder cases, motor cases, lighting fittings, water heaters, washing machines, refrigerators, stoves, air conditioners, dehumidifiers, fluorescent light housings, electrical heaters, toasters, microwave oven enclosures and switch boxes.

TRANSPORTATION

Containers, under body panels, bus & truck body panels, fuel tanks, noise screens, highway signs, air cleaners, conveyor systems and guard rails.

AGRICULTURAL EQUIPMENT

Barns, drying machines, animal houses, hoppers, irrigation systems, greenhouses, water tanks, sheds, silos, agricultural implements and feeders.

FURNITURE & OTHERS

Vending machines, drums, cans, pails, sauna inner parts, chimney pipes, entertainment machines, solar collectors, office equipment, steel furniture, tool boxes, garages and waste bins.

COMPUTER'S APPLIANCES

Computer shells and communication instruments。

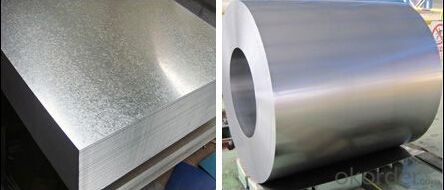

Surface Treatment:

Chromating treatment or anti-finger print

Surface Finished:

REGULAR SPANGLE:

Regular spangle is also called normal spangle which is naturally formed without any additional treatment during galvanizing.

MINI SPANGLE:

The spangle is restrained and formed as mini spangle by reducing the lead content in the zinc liquid or by blowing the zinc powder from the equipment installed on the zinc pot.

EXTRA SMOOTH:

The mini spangle is further skin-passed to produce the extra smooth surface.

- Q: How are steel coils inspected for formability using forming tests?

- To assess their ability to be shaped into desired forms without any defects or failures, steel coils undergo inspections for formability through the use of forming tests. These tests are conducted to evaluate the mechanical properties of the material and determine if it is suitable for specific applications. Forming tests consist of subjecting the steel coil to different forming operations, such as bending, deep drawing, or stretch forming. The coil is typically cut into specific dimensions and then subjected to these operations using specialized equipment. The main objective is to replicate the actual forming process that the steel will experience in real-world applications. During the forming tests, several parameters are carefully monitored. These parameters include the amount of force or load applied, the rate of deformation, and the resulting strain or deformation experienced by the steel. Additionally, the response of the coil to these operations is observed, including any visible defects like cracks, fractures, or surface imperfections. By thoroughly analyzing the performance of the steel coil during the forming tests, various characteristics related to formability can be determined. These characteristics include the material's ability to resist deformation, its capacity to withstand strain without failure, and its tendency to exhibit defects under specific forming conditions. The results obtained from these tests provide valuable insights into the suitability of the steel coil for particular forming processes and applications. Furthermore, advanced techniques such as digital image correlation and strain analysis can be utilized to precisely measure and evaluate the distribution of strain across the surface of the steel coil. These techniques assist in identifying areas of the coil that experience higher strain and potential points of failure. In summary, the formability of steel coils is assessed through forming tests that simulate the actual forming processes they will undergo. These tests evaluate various formability characteristics, including the material's resistance to deformation and its likelihood of defects. The results obtained from these tests aid in determining the suitability of the steel coil for specific applications and guide the selection of appropriate forming parameters.

- Q: How do steel coils contribute to the construction sector?

- Steel coils contribute to the construction sector in several ways. Firstly, they are used to manufacture structural components such as beams, columns, and steel frames, which provide strength and support to buildings and infrastructure. Secondly, steel coils are used to produce reinforcement bars that are embedded in concrete, enhancing its tensile strength and durability. Additionally, steel coils are utilized in the construction of bridges, pipelines, and other large-scale projects that require robust and long-lasting materials. Overall, steel coils play a vital role in the construction sector by providing the necessary materials for sturdy and resilient structures.

- Q: What are the different types of steel coil processing equipment?

- There are several different types of steel coil processing equipment used in the manufacturing industry. These equipment are designed to handle and process steel coils in various ways, allowing for efficient and accurate production. Some of the common types of steel coil processing equipment include: 1. Decoilers: Decoilers are used to unwind steel coils and feed them into the processing line. They are equipped with motorized systems that control the unwinding process, ensuring a steady supply of material. 2. Straighteners: Straighteners are used to flatten and straighten steel coils that may have become distorted during the coiling process. They use a series of rollers to remove any bends or waves in the material, ensuring a smooth and consistent feed into the next processing stage. 3. Slitters: Slitters are used to cut steel coils into narrower strips, allowing for the production of various widths of steel sheets or strips. They consist of multiple sets of circular blades that can be adjusted to cut the desired width. 4. Levelers: Levelers are used to correct any surface imperfections in steel coils, such as wavy or undulating surfaces. They use a series of rollers to apply pressure and reshape the material, resulting in a flat and even surface. 5. Shears: Shears are used to cut steel coils into specific lengths. They can be hydraulic or mechanical and are designed to provide clean and precise cuts, ensuring the desired dimensions are achieved. 6. Recoilers: Recoilers are used to rewind processed steel coils back into a tightly wound coil. They can be motorized or manual and are essential for storage and transportation purposes. 7. Edge trimmers: Edge trimmers are used to remove any excess material from the edges of steel coils. They ensure a clean and uniform edge, allowing for better handling and further processing. 8. Coil cars: Coil cars are used to transport steel coils within the processing facility. They are equipped with hydraulic or mechanical systems that allow for easy loading and unloading of coils onto other equipment. These are just some of the different types of steel coil processing equipment used in the industry. Each equipment plays a crucial role in the manufacturing process, ensuring the efficient production of high-quality steel products.

- Q: What is the thickness of a steel coil?

- The thickness of a steel coil can vary depending on the specific requirements and application. Typically, the thickness of a steel coil can range from a few millimeters to several centimeters.

- Q: im writing a book.-how is steel made? like, from what natural resources?-is there a type of factory that just prouduces steel to then be made into the various things made out of steel? if so, what kind of company might that be?-what is the first stage of steel, like, right after the other....ingrediants......are mixed, but before it is shaped into whatever its destined to be?thank you so much, i really appreciate it!

- That is an ENORMOUS subject that won't fit in this little box. Run an internet search on steel making. Essentially, steel is an alloy of iron and other metals chosen to give it the desired properties. These metals usually come from ores that are extracted from the earth. Actually, iron has too much carbon for most steel making purposes, and the carbon must be burned off. Iron is melted in a blast furnace, and oxygen is used to burn off the excess carbon. Then the molten metal is mixed with molten alloy metals and poured into molds to make ingots, which are blocks of steel of a size convenient for handling. Steel can also be made by re-melting scrap metal and adjusting the amounts of various adulterants or alloy metals at molten temperatures. The ingots are taken to rolling mills to be shaped into rods, pipes, sheet metal, and structural shapes. Molten iron and steel can also be poured into molds to produce complex shapes.

- Q: How are steel coils used in the production of aerospace structures?

- Various methods are employed in the production of aerospace structures, with steel coils being a key component. Aircraft frames and components are commonly manufactured using steel coils. These coils are processed through a series of operations, such as cutting, bending, and welding, to create the necessary structural members of an aircraft, including fuselage sections, wing spars, and landing gear. The preference for steel coils in aerospace applications is due to their exceptional strength and durability. They are capable of withstanding the immense forces and stresses experienced during flight and landing. By utilizing steel coils, aerospace structures are able to maintain the required structural integrity, even in harsh operating conditions. Moreover, steel coils are also utilized in the production of aerospace fasteners and connectors. These components are crucial for securely holding various parts and structures together. Bolts, screws, and rivets, which are essential for assembling different sections of an aircraft, are commonly manufactured using steel coil materials. The strength and reliability of steel coils make them ideal for fastening applications, ensuring the secure connection of aerospace structures. Additionally, steel coils find application in the production of aerospace equipment and machinery. Heavy machinery and specialized equipment are integral to aerospace manufacturing processes. Steel coils are frequently used in the construction of these machines, as they provide robust and sturdy frameworks. Tooling, jigs, fixtures, and molds, which are necessary for producing aerospace structures with precision and accuracy, often incorporate steel coils. In conclusion, steel coils play a vital role in the production of aerospace structures. They are utilized as raw materials for manufacturing aircraft frames and components, fasteners and connectors, as well as aerospace equipment and machinery. The strength, durability, and reliability of steel coils make them indispensable in the aerospace industry, ensuring the safety and integrity of aerospace structures.

- Q: Why are steel saucepans and tea kettles covered with copper on the outside and the bottom? what r the goals of having high-quality pans that are thick and tea kettles that are thin walled?

- Stainless steel is less conductive than copper. However, steel will retain heat longer and thus be distributed more evenly. (hence the thick bottoms, but also for balance). Copper on tea kettles is ideal to bring water up to a boil rapidly but since your not really cooking food, temperature distribution or control doesn't really matter. Now if your cooking sensitive food, then it does matter. For example, the use of a double boiler is preferred for chocolates. Temperature and distribution is critical. As far as relatively inexpensive copper clad pots and pans such as Revereware? Well, I don't see a difference but perhaps they did some testing.

- Q: How are steel coils used in the manufacturing of transmission shafts?

- Steel coils are used in the manufacturing of transmission shafts by being converted into cylindrical shapes through a process known as coil winding. These coils are then cut, shaped, and machined to create the desired dimensions and specifications for the transmission shafts. The high strength and durability properties of steel make it an ideal material for transmission shafts, ensuring efficient power transmission and overall performance of the machinery.

- Q: I need details for steel column splices welded or bolted. References or autocad blocks will be very useful. Thank you very much!

- Boy oh boy, that request would open you up to a bunch of different types of files and drawings. There are so many different ways to make a column splice for structural steels. And they all would depend greatly on the loads that the joint will be subject too. You need to find a copy of the Manual of Steel Construction Ninth edition (or newer if its out, mine is the ninth), from the AISC 'American Institute of Steel Construction. This book will show you quite a few different connection options, welded and bolted. You will need to make drawings from the dimensions and details you see in the book. One other thing, you might try to find a manual for steel detailing, the seventh edition of the above book had a section to show detailing dimensions for different steel elements, dependant on the size and shape of the member itself.

- Q: What are the different types of corrosion protection for steel coils?

- There are several different types of corrosion protection for steel coils, including galvanizing, paint coatings, organic coatings, and metallic coatings. Each method provides a barrier between the steel surface and the corrosive environment, preventing or slowing down the corrosion process. Galvanizing involves applying a layer of zinc to the steel surface, while paint coatings use various types of paints or primers. Organic coatings utilize polymers or resins to form a protective layer, and metallic coatings such as tin or aluminum can also be applied. The choice of corrosion protection method depends on factors such as the specific corrosive environment, desired lifespan, and cost considerations.

Send your message to us

Galvanized Stel coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords