Galvanized Steel Sheet for Roofing Purpose Q235 SS400 GRADE D

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction of Galvanized Steel Sheet for Roofing Purpose Q235 SS400:

Plain galvanized sheets are used for automotive body building, panels, electrical appliances like refrigerator, washing machine, and use for advertisement panels. Etc.

The thickness ranges from 0.5mm to 2mm in thickness and 900mm to 1250mm in width.

The coating also ranges from 120gsm to 240gsm

Galvanized plain sheets are manufactured using premium quality material which provides high tensile strength and makes them seepage resistant. GC sheets prove to be a cost effective solution for various construction purposes such as roofing, side-walls, partitions and panels.

2.Main features of Galvanized Steel Sheet for Roofing Purpose Q235 SS400:

.Corrugated Galvanized sheets are mainly used for roofing purpose.

.Corrugated galvanized sheets are generally termed as G.C. Sheet.

3. Galvanized Steel Sheet for Roofing Purpose Q235 SS400 Images:

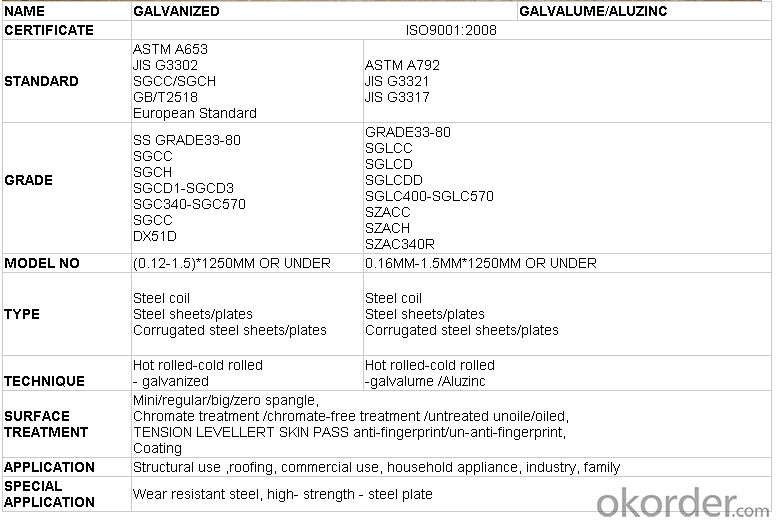

4. Galvanized Steel Sheet for Roofing Purpose Q235 SS400 Specification:

5.Our Factory:

6.FAQ:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets inEurope,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: How are steel sheets different from steel plates?

- Steel sheets and steel plates differ mainly in their thickness. Steel sheets are generally thinner, ranging from 0.4mm to 6mm in thickness, while steel plates are thicker, typically starting from 6mm onwards. Additionally, steel sheets are often used for decorative purposes, while steel plates are commonly utilized in structural applications where strength and durability are crucial.

- Q: What are the benefits of using pre-painted steel sheets?

- There are numerous advantages associated with the utilization of pre-painted steel sheets in various applications. To begin with, pre-painted steel sheets present an enhanced level of durability and longevity in comparison to alternative materials. The application of a paint coating on these sheets offers a protective barrier against corrosion, rust, and weathering, guaranteeing that the steel remains in exceptional condition for an extended period. Consequently, pre-painted steel sheets are highly suitable for outdoor usage, as they are constantly exposed to harsh environmental conditions. Moreover, pre-painted steel sheets offer a vast array of color options and finishes, providing greater flexibility in terms of design. Whether it is for architectural purposes, interior decoration, or industrial applications, the availability of diverse colors and finishes permits the creation of aesthetically pleasing and visually appealing structures or products. Additionally, pre-painted steel sheets are effortless to maintain and clean. The paint coating makes them resistant to stains, dirt, and grime, facilitating easier cleaning and reducing the need for extensive maintenance over time. This quality makes them an attractive choice for applications where cleanliness and hygiene are of utmost importance, such as in the food and beverage industry or healthcare facilities. Furthermore, pre-painted steel sheets are exceptionally versatile and can be employed in a wide range of industries and applications. From roofing and cladding to automotive components, appliances, and furniture, pre-painted steel sheets offer a reliable and cost-effective solution for diverse purposes. They can be easily fabricated, cut, and shaped into desired forms and sizes, making them suitable for various manufacturing processes. Lastly, pre-painted steel sheets exhibit environmentally friendly characteristics. The paint coatings utilized on these sheets are typically formulated to contain low levels of volatile organic compounds (VOCs), minimizing their impact on air quality and human health. Furthermore, the durability and longevity of pre-painted steel sheets contribute to an extended lifespan, thus reducing the need for frequent replacements and minimizing waste. In conclusion, the utilization of pre-painted steel sheets provides several benefits, including enhanced durability, a wide range of design options, easy maintenance, versatility, and environmental friendliness. These advantages establish pre-painted steel sheets as the preferred choice for numerous industries and applications.

- Q: Definition and application of steel sheet pile

- Cold rolled steel sheet pile is a steel structure formed by continuous rolling and forming of a sheet pile wall from a cold bending millNot knowing, then asked

- Q: Can steel sheets be used for sculptures and artwork?

- Yes, steel sheets can be used for sculptures and artwork. Steel is a versatile material that can be shaped, welded, and manipulated into various forms, making it suitable for creating sculptures and other artistic pieces. Its strength and durability also make it ideal for outdoor installations.

- Q: How long do steel sheets last?

- Steel sheets can last for many years, often surpassing the lifespan of other materials. The longevity of steel sheets depends on various factors such as the quality of the steel, the conditions it is exposed to, and how well it is maintained. In general, high-quality steel sheets that are properly installed and maintained can last for several decades or even longer. However, if steel sheets are exposed to harsh environments, such as extreme temperatures, humidity, or corrosive substances, their lifespan may be reduced. Regular inspections, cleaning, and maintenance can help extend the lifespan of steel sheets and ensure their durability over time.

- Q: What is the weight of steel sheets?

- The weight of steel sheets can vary depending on the thickness and dimensions of the sheet. Generally, steel sheets can range from a few pounds to several hundred pounds per square foot.

- Q: What is the average thermal expansion coefficient of steel sheets?

- The average thermal expansion coefficient of steel sheets varies depending on the specific type of steel and its composition. However, a commonly accepted average value for the thermal expansion coefficient of steel sheets is around 12 x 10^-6 per degree Celsius (12 parts per million per degree Celsius). It is important to note that this value is an approximation and can vary slightly depending on the specific grade and composition of the steel being used.

- Q: What are the different surface treatments for steel sheets?

- Steel sheets offer a range of surface treatments, each designed for specific purposes and offering unique advantages. Some commonly used treatments include: 1. Hot-dip galvanizing: Immersing the steel sheet in molten zinc forms a protective layer, providing excellent corrosion resistance. This treatment is ideal for outdoor applications like roofing, fencing, and automotive parts. 2. Electroplating: Using an electric current, a thin layer of metal such as chromium, nickel, or zinc is deposited onto the steel sheet. Electroplating enhances the appearance, corrosion resistance, and can improve wear resistance. 3. Powder coating: Dry powder is applied to the steel sheet and then baked to create a durable, smooth, and uniform finish. Powder coating offers excellent corrosion and impact resistance, and comes in various colors and textures, making it suitable for architectural, automotive, and appliance uses. 4. Painting: Applying paint to the steel sheet provides aesthetic appeal and protects against corrosion. Different types of paints, such as epoxy, polyurethane, or acrylic, can be used based on desired appearance and environmental conditions. 5. Passivation: This chemical treatment removes impurities and contaminants from stainless steel sheets, improving their corrosion resistance against oxidation and staining. 6. Electropolishing: By immersing the steel sheet in an electrolyte bath and applying an electric current, a thin layer of material is removed, resulting in a smoother, brighter surface that is more resistant to corrosion. These examples demonstrate the variety of surface treatments available for steel sheets. The most suitable treatment depends on factors like intended application, desired appearance, corrosion resistance requirements, and budget. Seeking advice from a steel sheet supplier or surface treatment specialist can help determine the optimal treatment for specific needs.

- Q: What is Larson steel sheet pile?"

- Use Larson steel sheet pile is very extensive, in the permanent structure, can be used for wharf, unloading field, Levee Revetment, retaining wall, retaining wall, breakwater, embankment, dock gate, etc.; in temporary structures, can be used for temporary expansion of bank, flow, large pipeline laying temporary cofferdam, bridge trench excavation retaining, retaining water, sand and so on; in the flood, and can be used for flood control, anti collapse, anti sand etc..

- Q: Can steel sheets be used for construction formwork or molds?

- Certainly, construction formwork or molds can utilize steel sheets, although their usage may not be as prevalent as materials like plywood or timber. Robust and enduring, steel sheets offer a sleek and uniform surface for concrete casting. They prove especially fitting for expansive construction ventures demanding formwork capable of withstanding immense pressures and loads. Additionally, steel sheets can be tailor-made and manufactured to meet precise project specifications, affording versatility in terms of shape, size, and arrangement. Nevertheless, the cost, weight, and accessibility of steel sheets should be weighed against alternative formwork materials prior to reaching a verdict.

Send your message to us

Galvanized Steel Sheet for Roofing Purpose Q235 SS400 GRADE D

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords