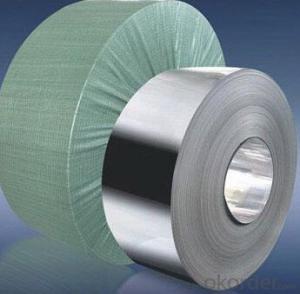

Galvanized Rolled Steel Coils Competive Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

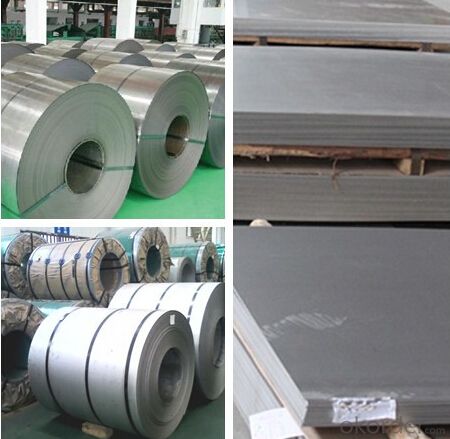

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Surface Treatment:Coated

Technique:Cold Rolled

Standard:ASTM, JIS, GB, AISI, DIN, BS

Steel Grade:Q195

Width:914, 1000, 1200, 1219, 1220, 1250

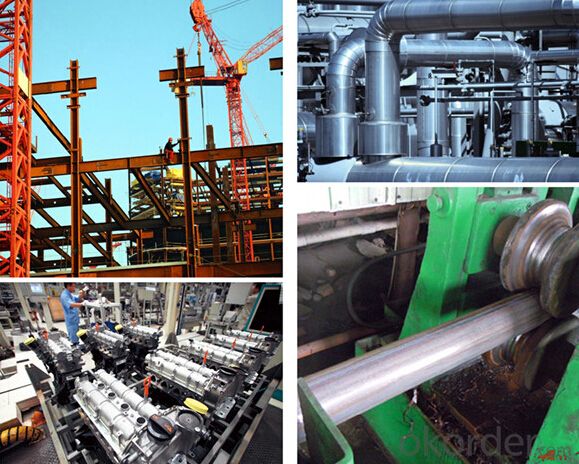

Export Markets:Global

Additional Info.

Trademark:STW

Packing:Sea Worthy Packing

Standard:0.2mm to 1.2mm

Origin:China

Production Capacity:10000 Tons Per Month

Product Description

Fit for world's standard (ASTM, JIS, EN)

Yeild strength: 235mpa to 550mpa

Width: From 600mm to 1250mm

Thickness: From 0.2mm to 1.2mm

Coating: AZ50, AZ100, AZ150

Other requirements fit for customer's demands

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

4.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

- Q: How are steel coils used in the production of metal fixtures?

- Steel coils are used in the production of metal fixtures as they are often the starting point for manufacturing processes. These coils are unwound and cut into specific lengths, which are then shaped, bent, and welded to create various metal fixtures such as shelves, brackets, and frames. The steel coils provide a consistent and high-quality raw material that can be easily formed and manipulated to meet the desired specifications of the fixtures being produced.

- Q: What are the common tests performed on steel coils?

- The common tests performed on steel coils include dimensional inspection, visual inspection, tensile testing, hardness testing, bend testing, and surface quality assessment. These tests ensure the quality, strength, and integrity of the steel coils before their use in various applications such as construction, automotive, and manufacturing.

- Q: who are the 7 best steel guitar players ever?

- Steel Guitar Players

- Q: What are the different types of steel coil surface treatments for corrosion resistance?

- There are several different types of steel coil surface treatments that are used to enhance corrosion resistance. These treatments are applied to the surface of the steel coil to create a protective layer that prevents corrosion and extends the lifespan of the steel. Some of the common types of surface treatments for corrosion resistance include: 1. Galvanizing: This is one of the most popular and effective methods for protecting steel against corrosion. In this process, a layer of zinc is applied to the surface of the steel coil. The zinc acts as a sacrificial anode, corroding before the steel does, thus protecting it from rust and corrosion. 2. Chromate conversion coating: This treatment involves applying a chromate-based solution to the surface of the steel coil. The chromate forms a thin film on the steel, providing a protective barrier against corrosion. It also enhances the adhesion of paint or other coatings that may be applied later. 3. Phosphating: Phosphating is a process where a phosphate coating is applied to the steel coil. This coating provides excellent corrosion resistance by forming a chemical bond with the steel surface. It also improves the adhesion of subsequent coatings or paints. 4. Organic coatings: These coatings, such as paint or epoxy, are applied to the steel coil to create a barrier between the steel and the surrounding environment. They provide both corrosion resistance and aesthetic appeal. The choice of organic coating depends on the specific application and the desired level of corrosion protection. 5. Zinc-rich paint: Similar to galvanizing, zinc-rich paint contains a high concentration of zinc particles. When applied to the steel coil, the zinc particles provide sacrificial protection, preventing corrosion. This coating is often used in harsh environments or for steel coils that will be exposed to frequent moisture or saltwater. It is important to note that the choice of surface treatment depends on various factors such as the application, environment, budget, and required level of corrosion resistance. Consulting with a steel coil manufacturer or corrosion specialist is recommended to determine the most suitable treatment for a specific situation.

- Q: What bike companies make the best Steel Road bikes?

- Lots of good companies out there. Surly Pacer is one to check out.

- Q: I wanna strip down my bike and take off all the paint... im thinking of leaving it just the steal color... Do i need to put anythinng on the steel to coat it or can i just leave it like that... Will it rust or anything?

- There is another thing you can do to inhibit corrosion on bare metal surfaces. Use a good quality automotive wax. Apply it with diligence, and keep the bike in the garage when you're not using it so it stays dry. Touch up the wax job every now and then to maintain the protective finnish.

- Q: How can I arbitrate quality of steel before purchasing it??

- The quality of the alloy can be very well be judged by its appearance and lustrous surface. The more luster on the surface the more refine will the steel be. To judge its tenacity and endurance, the alloy can be subjected to a series of procedures involving stress and shock. The reaction to these processes can determine whether the steel be fit for the purpose required.

- Q: How are steel coils used in the production of shipping vessels?

- Steel coils serve as a crucial ingredient in the manufacturing of shipping vessels. Typically crafted from high-strength steel, these coils are ideal for fabricating the ships' hulls and other structural elements. In the shipbuilding process, the steel coils undergo an initial unrolling and cutting phase, where they are fashioned into specific sizes and shapes in accordance with the ship's design. These pre-cut pieces are then joined together through welding or bolting, forming the vessel's framework. This framework provides the necessary sturdiness and rigidity to withstand the unforgiving conditions of the sea. Additionally, steel coils are employed in the creation of decks, bulkheads, and various internal components of the shipping vessels. Molded into different sections, these coils are subsequently assembled and affixed to the ship's structure. The utilization of steel coils in these areas guarantees longevity and resistance to corrosion, which are vital for the overall durability and safety of the vessel. Moreover, steel coils find application in the production of ship propellers, rudders, and steering mechanisms. These components play an integral role in controlling the ship's movement and direction. The utilization of high-strength steel coils ensures the requisite robustness and dependability, facilitating smooth and efficient navigation. In summary, steel coils occupy a pivotal position in the manufacturing of shipping vessels. They provide strength, durability, and corrosion resistance, and are incorporated into various aspects of ship construction, ranging from the hull to the decks, bulkheads, and internal components. Absent steel coils, the production of shipping vessels would face significant challenges, resulting in ships lacking the necessary structural integrity to navigate the seas safely and efficiently.

- Q: please i need your help in answering this question manufacturing process of steel containers and 20 references

- There are many types of steel containers and many different mnfg processes. There are also thousands of different steel alloys. Steel is used for canned food, compressed air cyclinders, hydraulic pressure vessels, electrical boxes, and many other containers. Steel containers are made out of sheet metal by soldering, brazing, spot welding, seam welding, riveting, bolting, screwing, etc. Heavier wall containers are fabricated of plate steel. Some steel containers are made by deforming the steel by extruding, forging, spin forming, drawing, ironing, etc. Some steel containers are made by machining. You should be able to find plenty of references if you search for these terms. good luck

- Q: How do steel coils contribute to the manufacturing of steel furniture?

- Steel coils are an essential component in the manufacturing of steel furniture as they serve as the raw material for creating various steel components. These coils are used to form and shape the different parts of the furniture, such as frames, legs, and supports. The coils are unwound and cut into the required lengths, then passed through various machines like presses and rollers to bend, shape, and join them together. This process allows for the customization and fabrication of the steel furniture, ensuring strength, durability, and the ability to withstand heavy loads. Overall, steel coils play a crucial role in shaping and forming the structural elements of steel furniture, providing the necessary strength and stability to the finished product.

Send your message to us

Galvanized Rolled Steel Coils Competive Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords