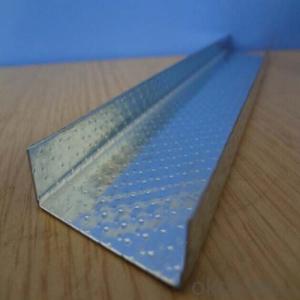

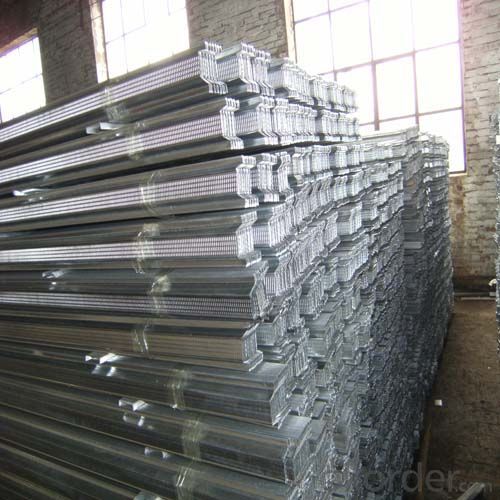

Galvanized Light Steel Profile and Wall Partition Stud and Track

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

The products are made of galvanized strips with good rust-Proof function, and they are seen in hotels, theaters, factories, houses, emporiums, offices, airplane-terminal buildings, bus stations, etc..

C metal stud is faced with plasterboard

U metal track is installed along the floor to fix metal stud

Specification

Specification for middle east:

Main Channel | 38x12 mm |

Furring Channel | 68x35x22 mm |

Wall angle | 25x25 mm |

C stud | 50x35 mm |

C Stud | 70x35 mm |

C stud | 75x35 mm |

U track | 52x25 mm |

U track | 72x25 mm |

U track | 75x25 mm |

Specification to Australia:

top cross rail | 25x21x0.75 mm |

25x21x0.75 mm | |

Furring Channel | 28x38x0.55 mm |

16x38x0.55 mm | |

Furring Channel track | 28x20x30x0.55 mm |

16x20x30x0.55 mm | |

Stud | 64x33.5x35.5 mm |

76x33.5x35.5x0.55 mm | |

Stud | 92x33.5x35.5x0.55 mm |

150x33.5x35.5x0.55 mm | |

Track | 51x32x32, 64x32x32x0.55 mm |

76x32x32x0.55 mm | |

Track | 92x32x32x0.55 mm |

Specification to Europe, Russia, UKrain, Georgia. etc

C Stud | 60x27 mm |

U track | 28x27 mm |

C stud | 50x50 mm |

C stud | 75x50 mm |

C stud | 100x50 mm |

U track | 50x40mm |

U track | 75x40 mm |

U track | 100x40 mm |

Product Overviews

Trade Shows

Main Markets: | 15.60% Southeast Asia |

13.2% Eastern Europe | |

12.3% Eastern Asia | |

12.00% North America | |

11.80% Mid East | |

10.8% Africa | |

9.50% South America | |

7.60% Oceania | |

6.70% Western Europe | |

Total Annual Sales Volume: | US$10 Million - US$50 Million |

Export Percentage | 51% - 60% |

Advantages and features:

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized steel strip zinc coating is 60-180g/m2.

3.Warm sales in Middle East , Africa , Australia, Malaysia ,and America , which have enjoyed an excellent reputation with high quality and services.

4. The specification can follow up customer requirements.

5. Advanced equipment can make sure exactly size, high quality products.

6.High quality cold rolled continuous hot galvanized plate as raw materials which makes sure it is anti-corrupt and anti-rusty

7.drywall steel profile adopts excellent manufacture equipment,advanced production process, scientific and detecting method.

8. Steel profile has beautiful surface, medium hardness! Good quality *competitive price large quantity *honesty *good after-service

Certificates ISO 9001:2000 Quality management system

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q: I was not a tool in the category, or else I got myself!

- I think you do so sound insulation is not the middle of the need to add sound insulation materials. There are many kinds, such as noise insulation cotton class. The more types of composite materials, the more layers, the sound and sound effects the best. It is best to have sound and sound effects have to reduce the sound of the rebound.

- Q: Light steel keel to do a layer of gypsum board layer of nine layers of the wall how much money a square, the price is simple or double-sided?

- The price is simple, carpentry is a board how much money, such as a ceiling, like a plate 90 so. Two boards have to double-sided settlement, how have one hundred fifty six one flat it

- Q: The designer said the solid wood flooring keel hit the prefabricated board after the lack of effort in the future may not be strong?

- With the filling block wall, and the same brick with the nail what is no problem, the weight is not heavy, the thinnest filling block is 120 thick, even the total thickness of double-sided plaster does not exceed 180, or light The partition wall is also the line, faster, but also durable, more than gypsum board wall to spend more, but at least the first nibbling nails are no problem, more durable and reliable, the weight is also light, the normal stay on the trip.

- Q: Light steel keel partition wall fire retardant coating shabu several surface

- Brush when, in accordance with the requirements, at least need to brush twice. Although the Tai Po people in practice only brush it again, but suggest that you still brush twice for safety.

- Q: Light steel keel wall Why use gypsum board to do grass-roots level?

- It is not necessary to use gypsum board but gypsum board there are many other materials can not replace the advantages of easy paint on the paint, such as latex is also its weight is more suitable for the keel does not have too much pressure on the pressure there are other advantages One by one in detail the gypsum board used in light steel keel partition is a good choice.

- Q: Light steel keel partition wall construction process is what

- Fixed Border keel: Border keylone along the position of the ball, the edge of the keel should be coincident with the elastic line. The end of the keel should be fixed, fixed point spacing should not be greater than lm, fixed should be solid.

- Q: What kind of new material is now called a "light partition" in the house? Is it safe?

- Light steel keel inorganic composite wall wall thickness of only about 175px, compared to the ordinary wall of about 300px, thin wall more space to save space, the estimated 110 square meters of the room, the use of light steel keel inorganic composite board Wall, can save about 1.6 square meters of space, so that the house to maximize the use of more spacious and comfortable space.

- Q: Light steel keel installed security door how loaded really

- Light steel keel its own strength is not very good, anti-theft door directly fixed on the light steel keel, then open the door will have a great impact on the light steel keel wall.

- Q: Curved gypsum board wall technology.

- Curved (sub-bumps) of the construction method: the first with the blockboard to make the first arc, in the right place with keel (wood keel, light steel keel can be) to shape the joinery board, and then gypsum board Attached to the blockboard and keel on the line. The following figure is the arc (concave) top of the grass-roots approach, curved wall practice with it the same.

- Q: How much does it cost to use a light steel keel gypsum board?

- 800 yuan to 1,000 yuan, which is the cost of the price If it is the company to do you probably about 1800-2,200 yuan.

Send your message to us

Galvanized Light Steel Profile and Wall Partition Stud and Track

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords