Galvanized Hot Rolled Channel Steel (UL, SGS, IEC and CE)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 38000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Galvanized Hot Rolled Channel Steel (UL, SGS, IEC and CE) Details

Standard: | AISI,ASTM,BS, DIN,GB,JIS | Dimensions: | 41*21*2.0 | Grade: | steel |

Place of Origin: | China (Mainland) | Brand Name: | CNBM | Model Number: | BSC-BS |

Shape: | C Channel | Application: | construction material or bracket | Perforated Or Not: | Is Perforated |

color: | Customized | certificates: | UL, NEMA, CE, IEC, SGS and ISO9001-2008 | business model: | manufacturer and exporter |

finish: | HDG/Pre-galvanized/Powder Coating/Electro | ||||

Packaging & Delivery

Packaging Detail: | Standard packaging or customized packaging |

Delivery Detail: | Usually within 20 days |

Galvanized Hot Rolled Channel Steel (UL, SGS, IEC and CE) Specifications

1. Specialized manufacturer and exporter

2. UL, cUL, CE, IEC, TUV and SGS

3. ISO9001-2008

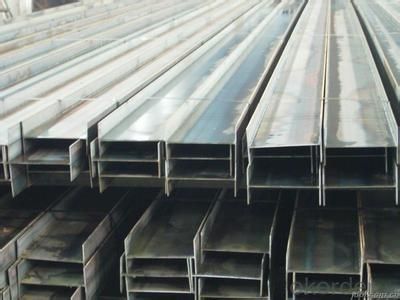

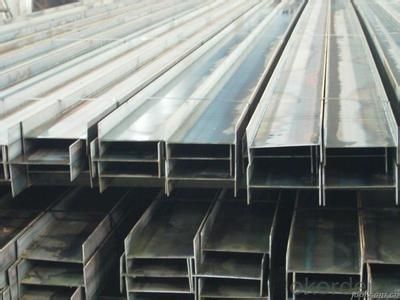

Galvanized Hot Rolled Channel Steel (UL, SGS, IEC and CE) Pictures

- Q: What is the allowable bending strength of Q235 channel steel? Why does the mechanical manual have no bending strength?

- Q235 channel design value of general 215N/mm^2, such as thin-walled steel pipe design values, such as 205N/mm^2.

- Q: Can steel channels be painted?

- Steel channels can indeed be painted, and this painting process can offer a protective layer that prevents corrosion and enhances their visual appeal. However, there are a few vital considerations to bear in mind when painting steel channels. Firstly, it is crucial to ensure that the surface of the channels is thoroughly clean and devoid of any dirt, grease, or rust. To achieve this, it is recommended to employ a wire brush or sandpaper to eliminate any loose particles and create a smooth surface for the paint to adhere to. Furthermore, it is of utmost importance to utilize a primer specifically formulated for metal surfaces. This will ensure appropriate adhesion and durability of the paint. Once the primer has been applied and allowed to dry, a suitable paint can be selected to coat the steel channels. It is essential to choose a paint that is compatible with metal surfaces and offers resistance to corrosion and weathering. In some cases, multiple coats of paint may be necessary to achieve the desired finish and durability. Overall, by properly preparing the surface and utilizing appropriate primers and paints, steel channels can be effectively painted to both protect and enhance their appearance.

- Q: Can steel channels be used in agricultural buildings?

- Yes, steel channels can be used in agricultural buildings. They provide structural support and durability, making them suitable for various applications such as framing, support beams, and roof trusses in agricultural structures.

- Q: Can steel channels be used for framing door and window openings?

- Yes, steel channels can be used for framing door and window openings. Steel channels provide a strong and durable support structure that can effectively handle the weight and stress of doors and windows. They offer stability and resistance to deformation, making them suitable for framing openings in residential, commercial, or industrial buildings. Additionally, steel channels can be easily customized and cut to the required dimensions, allowing for flexibility in design and construction.

- Q: Are steel channels available in non-standard lengths?

- Yes, steel channels are available in non-standard lengths.

- Q: What is the maximum length of steel channels?

- The maximum length of steel channels can vary depending on various factors such as the specifications provided by the manufacturer, the transportation limitations, and the practical considerations of handling and installation. However, in general, steel channels are commonly available in standard lengths ranging from 20 to 40 feet (6 to 12 meters). These lengths are often determined by the manufacturing process and the capabilities of the equipment used for cutting and forming the steel channels. It is important to consult with the manufacturer or supplier to determine the specific maximum length available for a particular type of steel channel.

- Q: What are the standard sizes of steel channels?

- The standard sizes of steel channels vary depending on the region and the specific industry standards being followed. In general, steel channels are available in a wide range of sizes to meet different construction and engineering requirements. Some common standard sizes of steel channels include C3x4.1, C6x8.2, C8x11.5, C10x15.3, C12x20.7, C15x33.9, C18x54.7, C20x66.3, and so on. These sizes represent the dimensions of the channel, such as the height, width, and weight per foot. It is important to note that these sizes may vary slightly based on the specific manufacturer or supplier. It is recommended to consult relevant industry standards or consult with a professional engineer to determine the appropriate size of steel channels for a specific application.

- Q: How do you mark the types of steel such as channel, I-beam and so on in the document?

- Channel letters are in capital letters "C" or "half brackets" [...], and "I" in capitals"

- Q: Can steel channels be used for supporting exterior artwork and sculptures?

- Yes, steel channels can be used for supporting exterior artwork and sculptures. Steel channels provide a strong and durable support structure, capable of withstanding various weather conditions. They offer stability and can be customized to fit the specific requirements of the artwork or sculpture, making them a suitable choice for supporting exterior installations.

- Q: How many meters per ton is channel ten?

- Channel ten, one ton, about 468 meters. Specific architectural manuals can be examined.Channel steel: the channel steel is a long strip steel with a cross section. Its specification means: such as 120*53*5, which means that the waist height is 120 millimeters, the width of the leg is 53 millimeters of channel, the waist is 5 mm thick channel, or called 12# channel steel. The same height of the channel, if there are several different leg width and waist thickness, also need to add a, B, C on the right side of the model to distinguish, such as 25a#, 25b#, 25c# and so on.

Send your message to us

Galvanized Hot Rolled Channel Steel (UL, SGS, IEC and CE)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 38000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords