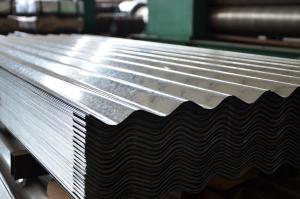

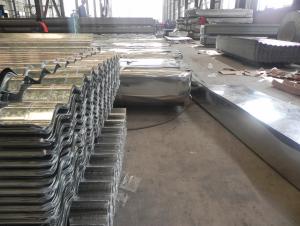

GALVANIZED CORRUGATION STEEL SHEET

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

GALVANIZED CORRUGATION STEEL SHEET

MATERIAL: FULL HARD, ZINC: 50G. CORRUGATION: 11NOS.

BUNDLE WEIGHT: 2-4MT, PACKAGE:SWAWORTHY PACKING

SIZE:0.3MM*900MM(1000 BEFORE)*3000

- Q: Are steel sheets suitable for earthquake-prone regions?

- Yes, steel sheets are suitable for earthquake-prone regions. Steel is known for its strength and durability, making it an excellent choice for construction in areas prone to seismic activity. Steel sheets can absorb and distribute the forces generated during an earthquake, reducing the risk of structural damage and collapse. Additionally, steel structures can be designed to flex and bend, allowing them to withstand the shaking caused by earthquakes without significant damage.

- Q: Can the steel sheets be easily drilled or machined?

- Yes, steel sheets can be easily drilled or machined. Steel is a versatile material that can be easily worked with using various tools and techniques. Drilling and machining steel sheets is a common practice in industries such as construction, manufacturing, and engineering. With the right equipment and expertise, steel sheets can be drilled or machined to create holes, shape the material, or achieve specific dimensions as needed for a particular application.

- Q: Can steel sheets be used for sound insulation?

- Yes, steel sheets can be used for sound insulation. They have high mass and density, which helps to block sound waves and reduce noise transmission. Additionally, steel sheets can be combined with other sound-absorbing materials, such as acoustic foam or insulation, to enhance their soundproofing capabilities.

- Q: How are steel sheets tested for quality?

- Steel sheets are tested for quality through a variety of methods to ensure they meet the required standards. One of the most common tests is the tensile strength test, which measures the maximum amount of stress a steel sheet can withstand before it breaks. This test is crucial as it determines the durability and reliability of the steel sheet in various applications. Another important test is the hardness test, which measures the resistance of the steel sheet to indentation or scratching. This is done using specialized tools such as a Brinell or Rockwell hardness tester. The hardness test helps determine the steel sheet's ability to withstand wear and tear, making it suitable for specific applications. The thickness of the steel sheet is also checked using a micrometer or ultrasonic thickness gauge to ensure it meets the required specifications. This is important as the thickness affects the sheet's strength and ability to withstand external forces. Furthermore, visual inspection is conducted to identify any surface defects, such as cracks, pits, or corrosion. This is done by trained professionals who carefully examine the steel sheet for any irregularities that might compromise its quality. Chemical composition analysis is another crucial test that determines the percentage of various elements present in the steel sheet. This analysis is performed using techniques like spectrometry or X-ray fluorescence to ensure the steel sheet meets the desired chemical requirements. Additionally, steel sheets may undergo tests such as impact testing, bend testing, and fatigue testing to assess their performance under specific conditions. These tests simulate real-world scenarios to ensure the steel sheet can withstand the anticipated loads and stresses it may encounter. Overall, steel sheets are rigorously tested for quality to ensure they meet the necessary standards, providing customers with reliable and durable products. These tests help manufacturers identify any potential flaws or defects, allowing them to rectify issues and deliver high-quality steel sheets to the market.

- Q: What is the maximum temperature that steel sheets can withstand?

- The maximum temperature that steel sheets can withstand depends on the grade and type of steel. Generally, most steel alloys can withstand temperatures up to around 1,300 to 1,500 degrees Fahrenheit (700 to 800 degrees Celsius) before the material starts to weaken and lose its structural integrity. However, specialized high-temperature steels can withstand even higher temperatures, reaching up to 2,300 degrees Fahrenheit (1,260 degrees Celsius).

- Q: What's the best way to open a 10mm thick steel sheet?

- Steel plate is a kind of flat steel with big width ratio and large surface area. According to the thickness of plate Ya divided into thick and thin plates two specifications.

- Q: Can steel sheets be used for food storage containers?

- No, steel sheets are not typically used for food storage containers as they can corrode and lead to contamination of the food. Food-grade materials like stainless steel or food-safe plastics are preferred for this purpose.

- Q: Can steel sheets be used for manufacturing containers or packaging?

- Yes, steel sheets can be used for manufacturing containers or packaging. Steel is a durable and strong material that provides excellent protection and is commonly used in the production of containers and packaging for various industries.

- Q: What is the difference between a galvanized and aluminum steel sheet?

- A galvanized steel sheet is made from carbon steel that has been coated with a layer of zinc to protect it from corrosion. This process, known as galvanization, involves immersing the steel sheet in a bath of molten zinc, which forms a protective layer on the surface. Galvanized steel sheets are known for their durability, as the zinc coating acts as a barrier against moisture, chemicals, and other corrosive elements. They are commonly used in construction, automotive, and industrial applications. On the other hand, an aluminum steel sheet is made from aluminum, which is a lightweight and corrosion-resistant metal. Aluminum sheets are manufactured by rolling aluminum ingots into thin sheets of varying thicknesses. They offer excellent corrosion resistance, even without additional coatings or treatments. Aluminum sheets are commonly used in aerospace, transportation, and architectural applications. In terms of differences, the main distinction between galvanized and aluminum steel sheets lies in their composition and protective properties. Galvanized steel sheets have a zinc coating, which provides superior corrosion resistance compared to bare carbon steel. This makes them more suitable for outdoor and high-moisture environments. Additionally, galvanized steel sheets can be easily welded and painted, offering more versatility in terms of customization. On the other hand, aluminum steel sheets have inherent corrosion resistance due to the presence of aluminum. They are lighter in weight than galvanized steel sheets, making them more suitable for applications where weight reduction is a priority. Aluminum sheets also have better thermal conductivity and reflectivity properties, making them ideal for applications involving heat dissipation or insulation. In summary, galvanized steel sheets are carbon steel sheets coated with a layer of zinc for enhanced corrosion resistance, while aluminum steel sheets are made from aluminum and offer inherent corrosion resistance. The choice between galvanized and aluminum steel sheets depends on the specific requirements of the application, such as the level of corrosion protection needed, weight considerations, and thermal properties desired.

- Q: Are steel sheets easy to clean and maintain?

- Yes, steel sheets are easy to clean and maintain. They are resistant to stains, rust, and corrosion, and can be easily wiped clean with a damp cloth or mild cleaning solution. Additionally, steel sheets do not require frequent maintenance or special care, making them a convenient and durable choice for various applications.

Send your message to us

GALVANIZED CORRUGATION STEEL SHEET

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords