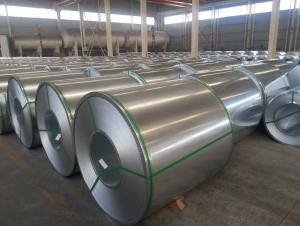

Galvalume STEEL coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Specification:

Thickness: 0.2-3.0mm

Width: 600-1500mm

Coating Mass: Z08,Z12,Z18,Z20,Z22,Z25,Z27,Z35

Z80,Z120,Z180,Z200,Z220,Z250,Z275

Tolerance for thickness,width,flatness and so on conform to the requirements of JIS G3302 or ASTM A653M/924M

Coil ID can be either 508mm or 610mm, maximum coil OD is 2000mm

The speicfication of ASTM Such as A653m,A924 M and so on have been updated to the latest revisions

Application:

BUILDING & CONSTRUCTION

Floor decks, ceilings, verandas, rolling doors, warehouse, partitions, sheds, gutters, wall, underground piping, sashes, beams, fences, scaffolding, indoor decorations, ducts, ventilating pipes, steel frames and cable trays.

ELECTRICAL APPLIANCES

Freezers, video recorder cases, motor cases, lighting fittings, water heaters, washing machines, refrigerators, stoves, air conditioners, dehumidifiers, fluorescent light housings, electrical heaters, toasters, microwave oven enclosures and switch boxes.

TRANSPORTATION

Containers, under body panels, bus & truck body panels, fuel tanks, noise screens, highway signs, air cleaners, conveyor systems and guard rails.

AGRICULTURAL EQUIPMENT

Barns, drying machines, animal houses, hoppers, irrigation systems, greenhouses, water tanks, sheds, silos, agricultural implements and feeders.

FURNITURE & OTHERS

Vending machines, drums, cans, pails, sauna inner parts, chimney pipes, entertainment machines, solar collectors, office equipment, steel furniture, tool boxes, garages and waste bins.

COMPUTER'S APPLIANCES

Computer shells and communication instruments。

Surface Treatment:

Chromating treatment or anti-finger print

Surface Finished:

REGULAR SPANGLE:

Regular spangle is also called normal spangle which is naturally formed without any additional treatment during galvanizing.

MINI SPANGLE:

The spangle is restrained and formed as mini spangle by reducing the lead content in the zinc liquid or by blowing the zinc powder from the equipment installed on the zinc pot.

EXTRA SMOOTH:

The mini spangle is further skin-passed to produce the extra smooth surface.

- Q: How do steel coil manufacturers stay updated with industry trends?

- Steel coil manufacturers utilize various methods to stay informed about industry trends: 1. Attending industry conferences and trade shows allows manufacturers to connect with other professionals, attend seminars and presentations, and learn about the latest trends and innovations in the steel coil industry. 2. Subscribing to industry publications and magazines provides manufacturers with regular updates on trends, market insights, and technological advancements in the steel coil industry. These publications often feature articles and interviews with experts, delivering valuable information to stay updated. 3. Actively participating in online forums, discussion boards, and social media groups dedicated to steel coil manufacturing helps manufacturers stay connected with the industry. These platforms allow them to engage with peers, share knowledge, ask questions, and stay updated on the latest trends. 4. Maintaining close relationships with suppliers and customers enables manufacturers to gain insights into changing market demands, new product requirements, and emerging trends. Suppliers and customers often share information about industry trends and advancements that assist manufacturers in adapting their processes accordingly. 5. Investing in continuous education and training programs for employees ensures that the workforce remains updated on the latest industry trends, technological advancements, and best practices. Prioritizing employee development equips manufacturers with the skills and knowledge necessary to stay ahead of the curve. 6. Allocating resources for research and development activities allows steel coil manufacturers to explore new materials, manufacturing techniques, and technologies. By investing in R&D, manufacturers can stay at the forefront of industry trends and develop innovative solutions that meet evolving customer demands. 7. Staying updated with government regulations, industry standards, and certifications that impact the steel coil industry is crucial. Compliance with these regulations often requires manufacturers to adopt new practices, technologies, or materials, ensuring that they remain up to date with the latest trends and requirements. By actively engaging in these activities, steel coil manufacturers can stay informed about industry trends, emerging technologies, and market demands. This enables them to adapt their processes, products, and strategies to remain competitive and meet the evolving needs of their customers.

- Q: Is Carbon Steel strong for swords?

- Depends on the sword design. Some swords are high carbon, some a low carbon, some are made from a billet of alternating high and low carbon ('Damascus' steels). It all depends on what characteristics you want for your sword. Softer steels won't hold an edge as well but they offer great flexibility so your sword won't shatter when they make impact with armor or shields. Harder steels hold better edges but they're prone to binding in wooden shields and then being broken as soon as a bending force is applied along the weak axis of the blade. Japanese Katanas have both hard and soft steels to allow the blade to bend yet still hold strong edges. If you're making the sword from raw materials on your own, look up some different recipes for crucible steel. It's probably the most fun and involved process.

- Q: How are steel coils used in the construction of bridges?

- Steel coils are indispensable in the construction of bridges, as they are typically crafted from high-strength steel and serve various purposes throughout the bridge-building process. One of the primary functions of steel coils in bridge construction lies in the production of structural components. These coils are cut, shaped, and welded together to form beams, columns, and trusses, thus ensuring the bridge's stability and durability. Moreover, steel coils are employed in fabricating bridge decks, which serve as the upper surface of the bridge, providing a pathway for vehicles and pedestrians. The coils are rolled into sheets and further processed to create the deck plates, which are then assembled and attached to the bridge's structural elements. Another significant application of steel coils in bridge construction involves reinforcing concrete structures. Rebar, derived from steel coils, is embedded within the concrete to enhance its strength and resistance to tension. Strategically placed in locations such as bridge piers and abutments, the rebar provides additional support, preventing cracking or collapse. Furthermore, steel coils find utility in the manufacturing of bridge expansion joints. These vital components allow bridges to expand and contract in response to temperature fluctuations and external factors. By shaping steel coils into plates or strips, expansion joints can be easily installed and adjusted to accommodate the bridge's movement. To summarize, steel coils play a vital role in the construction of bridges, contributing to the manufacturing of structural components, bridge decks, reinforcing concrete structures, and expansion joints. With their strength and support, steel coils facilitate the creation of safe and reliable bridges, capable of withstanding diverse loads and environmental conditions.

- Q: What is the average amount carbon emissions of steel per pound produced?

- Carbon okorder /... - Similar pages - Life-cycle energy and emissions of marine energy devices | Carbon ...Carbon dioxide emissions per unit mass of steel: 1.75 tCO2/tonne steel ; Total mass of steel in device: 665 tonnes ; Carbon dioxide emissions due to .

- Q: What are the quality standards for steel coil production?

- The quality standards for steel coil production typically include factors such as dimensional accuracy, surface finish, mechanical properties, chemical composition, and adherence to industry-specific standards and specifications. These standards ensure that the steel coils meet the required strength, durability, and performance criteria, and are suitable for various applications in industries like automotive, construction, and manufacturing.

- Q: What's the difference between hot rolled coil and hot-rolled carbon thin steel coil?

- The difference between hot rolled primary and hot-rolled carbon thin steel coils is that they include carbon steel rolls and low alloy steel coils.

- Q: How do steel coil manufacturers ensure fair pricing?

- Various measures are taken by steel coil manufacturers to ensure fair pricing. To begin with, extensive market research is conducted to understand the current trends in the industry, the dynamics of supply and demand, and the pricing strategies of competitors. This information helps them determine a pricing strategy that is both competitive and fair, in line with market standards. In addition, the cost of raw materials, production, and operational expenses are carefully considered in order to establish a reasonable base price. The manufacturers also take into account economies of scale, as larger production volumes can result in lower costs per unit. Furthermore, steel coil manufacturers often establish long-term partnerships with suppliers to guarantee a stable and consistent supply of raw materials at fair prices. This allows them to maintain a reasonable cost structure and minimize fluctuations in pricing. Moreover, these manufacturers prioritize transparency in pricing by providing detailed quotations that break down the cost components. This enables customers to understand the factors contributing to the final price and ensures fairness in the pricing process. To further promote fairness, steel coil manufacturers take into account the specific requirements of each customer. They may offer customized pricing based on factors such as order volume, delivery timelines, and value-added services. This approach ensures that each customer receives a price that is tailored to their unique needs and requirements. Overall, steel coil manufacturers employ market research, cost considerations, transparent pricing practices, and customized pricing options to ensure fair pricing. Their goal is to create a pricing environment that is fair and mutually beneficial for both themselves and their customers.

- Q: Are steel coils used in shipbuilding?

- Yes, steel coils are commonly used in shipbuilding. They are used primarily for the construction of the ship's hull and other structural components due to their strength, durability, and ability to withstand harsh marine environments.

- Q: can u use stainless steel to make a coin? why or why not? answers based on facts plz.

- Stainless steel has been used by some countries to make coins, but it's not an ideal metal. When a coin is struck, a die comes down and strikes the blank with many tons of force (the blank is also sitting on top of another die--one has the image on the obverse (front) of the coin, while the other die has the image of the reverse of the coin). When the die strikes the blank, the force causes the metal in the blank to flow into the recesses of the die. The problem with stainless steel is that it doesn't want to flow into the die. To get an image, either the relief (how high the raised portion of the design will be) has to be very low, and the coin has to have a simple design, or they have to greatly increase the pressure of the strike. This slows the coining press down, and greatly shortens the life of the dies.

- Q: Hi, I need to know why stainless steel is rust proof please tell me its for my science project. :)

- Why doesn't stainless steel rust? Nancy Avery, New London, Conn. Metallurgical engineer Michael L. Free of the University of Utah offers this explanation: Stainless steel remains stainless, or does not rust, because of the interaction between its alloying elements and the environment. Stainless steel contains iron, chromium, manganese, silicon, carbon and, in many cases, significant amounts of nickel and molybdenum. These elements react with oxygen from water and air to form a very thin, stable film that consists of such corrosion products as metal oxides and hydroxides.

Send your message to us

Galvalume STEEL coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords