Gabion Boxes/Stone Cages/Gabion Basket With Best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

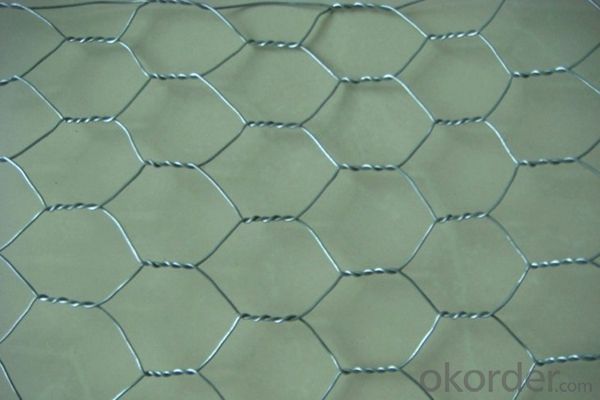

1:Gabion Box Materials

1.Galvanized steel wire :low carbon steel wire

2.Zinc-5% aluminum-mixed mischmetal alloy steel wire ,a new-type material

3.Galvanized steel wire ,PVC or PE coating

2:Gabion Box Process

wire drawing---galvanized--- galvanized after weaving or galvanized before weaving.

3:Gabion Box Packing

50-100 gabion wire mesh /per bundle,wrapped with 2 to steel strips

4:Gabion Box Payment term

30% T/T in advance as deposit and 70% balance upon delivery.

5:Gabion Box Delivery time

20 days after receive the deposit

6:Gabion Box Color

PVC coated hexagonal wire mesh is green, white, grey or other colors; enamelled hexagonal wire mesh is green.

7:Gabion Box Features

1.It is very economical . You just need to put stone in the mesh and then seal it .

2.It is flexible ,corrosion resistant and can stand up to extreme weather.

3.Simple construction,requiring no special technique.

4.The silt between the wire mesh and stone contributes to plant growth.this makes the gabion wire mesh harmoni ous with the surrounding natural environment .

5.The gabion wire mesh is folding and can be assembled site,which saves on transport cost.

8:Gabion Box Details Specification

Opening (mm) | Wire Diameter (mm) | Wire Diameter(PVC Coated) Inner/outside(mm) | Strands |

60x80 | 2.0-2.8 | 2.0/3.0-2.5/3.5 | 3 |

80x100 | 2.0-3.2 | 2.0/3.0-2.8/3.8 | 3 |

80x120 | 2.0-3.2 | 2.0/3.0-2.8/3.8 | 3 |

100x120 | 2.0-3.4 | 2.0/3.0-2.8/3.8 | 3 |

100x150 | 2.0-3.4 | 2.0/3.0-2.8/3.8 | 3 |

120x150 | 2.0-4.0 | 2.0/3.0-3.0/4.0 | 3 |

Gabion Size(m) | Mesh Model | |||||

8x10 | 6x8 | |||||

Length | Width | Height | Gal. or PVC coated | Gal. or PVC coated | ||

Mesh wire diameter | Gal. weight | Mesh wire diameter | Gal. weight | |||

2m | 1m | 1m | 2.7mm | >245g/m2 | 2.0mm | >215g/m2 |

3m | 1m | 1m | Selvedge wire diameter | Gal. weight | Selvedge wire diameter | Gal. weight |

4m | 1m | 1m | 3.4mm | >265g/m2 | 2.7mm | >245g/m2 |

6m | 1m | 1m | Lacing wire 2.7mm | Lacing wire 2.0mm | ||

9:Gabion Box Application

Welded gabion mesh is widely used for the control and guide of water; preventing of rock breaking; water and soil, roadway and bridge protection; strengthening structure of soil; protection engineering of seaside area and retaining wall structures; hydraulic structures, dams and culverts; coastal embankment works; architectural feature retaining walls.The main application as follows:

a. Control and guide of water or flood

b. Flood bank or guiding bank

c. Preventing of rock breaking

d. Water and soil protection

e. Bridge protection

f. Strengthening structure of soil

g. Protection engineering of seaside area.

- Q: Can steel wire mesh be used for playground equipment?

- Certainly, playground equipment can utilize steel wire mesh. Steel wire mesh proves to be a highly adaptable and sturdy substance, offering a multitude of advantages for playground equipment. It is frequently employed in the construction of partitions, enclosures, climbing frames, and protective nets within playgrounds. The robustness and tenacity of steel wire mesh render it apt for supporting the weight of children and ensuring their safety during playtime. Furthermore, steel wire mesh exhibits a resistance to corrosion and can endure diverse weather conditions, thus establishing itself as a durable choice for playground equipment. The mesh's design also permits excellent visibility and ventilation, fostering a secure and enjoyable environment for play.

- Q: How is steel wire mesh used in landscaping?

- Steel wire mesh is commonly used in landscaping for various purposes. One of the main applications is for creating fences or barriers to demarcate specific areas within a garden or landscape. Steel wire mesh fences are durable, sturdy, and provide a strong boundary that helps keep unwanted animals or intruders out. They can also be used to create enclosures for pets or to protect specific plants or flower beds from being trampled on or damaged. Another common use of steel wire mesh in landscaping is for supporting climbing plants or vines. By attaching the mesh to a structure or a wall, it provides a framework for the plants to grow and cling onto. This not only adds an aesthetically pleasing element to the landscape but also helps to create privacy or shade in specific areas. Moreover, steel wire mesh can be used to create trellises or screens for plants, such as tomatoes or beans, that require support as they grow. The mesh provides a framework for these plants to climb on, allowing them to grow vertically and saving space in the garden. In addition, steel wire mesh can be used for erosion control in landscaping projects. By placing the mesh on slopes or embankments, it helps to stabilize the soil and prevent erosion caused by rainwater or wind. This is particularly important in areas prone to erosion or in landscapes where maintaining the integrity of the soil is crucial. Overall, steel wire mesh is a versatile material in landscaping that offers a range of applications, including creating fences, supporting climbing plants, providing structure for trellises or screens, and controlling erosion. Its durability, strength, and flexibility make it a popular choice for landscape designers and homeowners alike.

- Q: Can steel wire mesh be used for sports equipment?

- Yes, steel wire mesh can be used for sports equipment. Steel wire mesh is a versatile material that is known for its strength and durability. It can be used in various sports equipment such as fencing for tennis courts or soccer fields, basketball backboards, baseball cages, and even as protective netting for golf courses or batting cages. The steel wire mesh provides a sturdy and secure structure, ensuring the safety of players and spectators. Additionally, the open design of the mesh allows for good visibility, making it ideal for sports equipment where clear sightlines are important.

- Q: How does steel wire mesh perform in terms of resistance to wear?

- Steel wire mesh performs exceptionally well in terms of resistance to wear. The high tensile strength of steel wire makes it extremely durable and capable of withstanding various forms of wear and tear. The mesh structure prevents it from easily fraying or breaking under pressure, ensuring a long lifespan even in high-stress applications. Additionally, steel wire mesh is highly resistant to corrosion, rust, and other forms of chemical deterioration, further enhancing its wear resistance. Whether used in construction, industrial settings, or even as fencing, steel wire mesh is known for its ability to endure heavy usage and maintain its structural integrity over time.

- Q: What are the common uses of steel wire mesh in construction?

- Steel wire mesh is commonly used in construction for a variety of purposes such as reinforcing concrete, providing structural support, creating barriers and fences, and facilitating the installation of plaster and stucco.

- Q: Can steel wire mesh be used for gabion mattresses?

- Yes, steel wire mesh can be used for gabion mattresses. Gabion mattresses are flexible structures made of wire mesh filled with stones or other materials. The steel wire mesh provides the necessary strength and stability to hold the stones in place, making it suitable for constructing gabion mattresses.

- Q: How is steel wire mesh different from other types of wire mesh?

- The unique properties and characteristics of steel wire mesh set it apart from other types of wire mesh. Firstly, its exceptional strength and durability make it ideal for applications that require high load-bearing capacity or resistance to impacts and abrasion. This is achieved through the use of high-quality steel wires tightly woven or welded together to create a sturdy structure. Secondly, steel wire mesh offers excellent corrosion resistance. It is often coated with protective materials such as galvanization or stainless steel, which prevent rust and corrosion even in harsh environments. This makes it suitable for outdoor applications or industries that involve exposure to moisture, chemicals, or extreme temperatures. Additionally, steel wire mesh is highly versatile and can be customized to meet specific requirements. It comes in various mesh sizes, wire diameters, and patterns, allowing for different levels of openness, flexibility, and aesthetic appeal. It can also be further modified through cutting, bending, or shaping to fit specific applications or architectural designs. Lastly, steel wire mesh finds extensive use in a diverse range of industries and applications. It is commonly used in construction, infrastructure, mining, agriculture, filtration, and even artistic or decorative purposes. Its versatility, strength, and corrosion resistance make it a preferred choice for many professionals and industries. To summarize, steel wire mesh stands out from other wire mesh options due to its exceptional strength, durability, corrosion resistance, versatility, and wide range of applications.

- Q: How does steel wire mesh perform in terms of vibration absorption?

- The remarkable vibration absorption capabilities of steel wire mesh are well-known. The mesh's structure, comprised of interconnected wires, enables it to effectively dissipate and dampen vibrations. When the mesh is subjected to a vibrating force, the wires within it stretch and flex, absorbing the energy of the vibration. This results in a reduction in the amplitude and intensity of the vibrations, creating a smoother and more stable environment. Furthermore, the tightly woven nature of steel wire mesh offers an additional advantage in terms of vibration absorption. The small gaps between the wires restrict the movement of the vibrating particles, limiting their ability to propagate and transmit vibrations. This enhances the mesh's capacity to absorb and dissipate vibrations across its entire surface, making it an ideal material for applications that require vibration control. Steel wire mesh finds common use in various industries, including construction, automotive, and aerospace, where it is necessary to minimize or control vibrations. It is often employed as a vibration isolation material in the form of mesh sheets or panels, which can be easily installed in different structures and equipment. Furthermore, steel wire mesh can be customized in terms of wire diameter, weave pattern, and mesh size to further optimize its vibration absorption properties for specific applications. In summary, steel wire mesh exhibits exceptional performance in terms of vibration absorption due to its flexible and interconnected wire structure, as well as its tightly woven pattern. Its ability to dissipate and dampen vibrations makes it a reliable choice for reducing the impact of vibrations in various industries and applications.

- Q: What are the properties of steel wire mesh?

- Steel wire mesh is a versatile material with several key properties. It is durable, strong, and resistant to corrosion, making it ideal for various applications. The mesh is flexible and can be easily shaped or cut to fit specific needs. It also provides excellent visibility and airflow while effectively containing or separating objects, making it suitable for fencing, filtration, reinforcement, and other purposes.

- Q: Is steel wire mesh suitable for landscape design?

- Steel wire mesh proves to be an ideal choice for landscape design. Its versatility allows for a multitude of applications that not only enhance the aesthetics but also the functionality of outdoor spaces. Whether it's for fencing, trellises, or screens, this material offers both boundaries and privacy while introducing a contemporary and industrial vibe to the landscape. Moreover, the construction of raised beds becomes effortless with steel wire mesh, offering flexibility and creativity in gardening options. Furthermore, it serves as a sturdy support structure for climbing plants, enabling the creation of stunning vertical gardens. Its enduring durability and strength guarantee a long-lasting option that withstands harsh weather conditions and resists corrosion. By seamlessly blending with different materials and styles, steel wire mesh unlocks limitless possibilities for landscape design.

Send your message to us

Gabion Boxes/Stone Cages/Gabion Basket With Best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords