Full-Automatic AAC Product Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 30 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description of Full-Automatic AAC Product Line

1.Environment- friendly

2.low operating cost

3.reliable operation

4.Earthquick-proof

The Development and Features of Full-Automatic AAC Product Line

AAC has a history of one hundred of years and has become the pillar industry in construction field.In our country aerated technique have been developed for about 40 years,and its technique skills and equipements are becoming mature.The AAC has the features of light bulk density,good thermal insulation properties and sound-absorption, certain strength and process ability,and its raw materials is very rich,especially the reuse of fly ash enables the comprehensive utilization of industrial residue,curb environmental pollution,no destroy on farmland,creat good social and economic benefits.AAC is a ideal alternative of the traditional clay brick wall materials.For many years AAC has been strongly supported by national wall reform policy,tax policy and environmental policy.In a sentence,AAC has been an important factor in new building materials and has a broad market prospect.

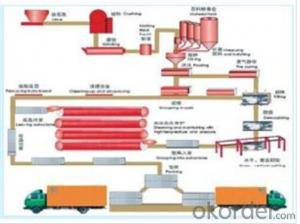

AAC Processing Technics:

1.Storing and supplying of raw meterials of AAC blocks.

All raw meterials are carried into factory by trucks.Fly ash,sand or lime are gathered in specified raw materials field waiting for using.Sacks of cement and bulk cements stored in cement warehourse.Chemicals and aluminum powder are seperatedly keeped in chemical warehourse and aluminum warehourse.When used,these raw materials are carried into workshop respectively.

2.Processing of raw materials:

Quick lime is sent by vibrating feeder and belt conveyor into jaw crushers to smash. Smashed lime is sent into lime silo by bucket elevator and then is transported into ball mills by screw conveyer. Fined materials are sent into proportion bin by screw conveyer and bucket elevator.Aluminium powder is lifted by a truss motor to second layer of batch planta and empty into mixer.Then quota water is poured to make aluminium powder into suspension.

3.Aerated block Ingredients,Stiring and Casting

Fly ash (or sand or stone powder )and waste slurrry are measured in mesuring tank.After the measuring and mould in their place,slurry stirring begins.Slurry temperature should reach about 40°-This is technical requiremnents.If the actual temperture doesn’t arrive 40°,vapor is used in the measuring tank to raise temperature.Half or one minutes before casting,aluminium suspension is supposed to be added to the slurry.

4,Pre-curing and Cutting Process

Cut model is conveyed to precuring room for gas forming. Room tempreture should range from 50°to 70°.This period lasts one hour and a half totwo hours.(If materials take on geographical advantages,this precuring can be eliminated.Precured green body together with mould frame will be lifted to cutting station that is covered by autoclave board .After frame detachment,cutting machine do cross-cutting, vertical cutting, face-milling and tip-binding. At the same time, die grid is hanged to precuring cart for manual cleaning and degresing to prepare for the next perfusion. The cutting ready embryois are carried to precuring cart together with die seat, palletizing in two tiers, four pillars between two the tiers, and get into grouping process.When the cutting of body is completed, partial waste materials cut down will be processed into waste material slurry which then will be pumped to the slurry tank located at the topmost story of batching building, after that, add the necessary raw material, then transported into a pulping machine for reuse.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 2010 |

| Annual Output Value | |

| Main Markets | South America Southeast Asia Africa Mid East Eastern Asia South Asia |

| Company Certifications | Certificate of registration |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | 3,000-5,000 square meters |

| No. of Production Lines | Machinery industrial park, zhengzhou city, Henan province,China |

| Contract Manufacturing | Above 10 |

| Product Price Range | OEM Service Offered |

Send your message to us

Full-Automatic AAC Product Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 30 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords