Fully Automated Flyash/Sand AAC Block Production Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

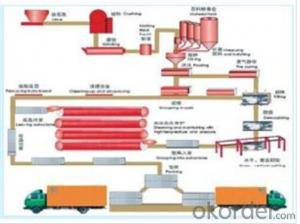

fully-automated flyash/sand aac production line

1.potential industry future

2.low invest,high profit

3.we are manufacturer

At present, more and more Indian business man are interested in fully-automated flyash/sand aac block production line, during the high development of the civil construction, aac block play an important actor in this.Our company is the professional fully-automated aac block production line manufacturer for many years with rich experience, we can design the layout of fully-automated flyash/sand aac block production line(aac plant) for you, give the professional advice and provide the technical support until you produce the standard aac block for free. Choosing our company will be your best choice for the fully-automated flyash/sand aac production line.

Pre-sales of fully-automated flyash/sand aac block production line for customers:

1. Based on customer's requirement, we select equipment type in the principle of "Best cost performance is reached with most economical investment".

2. Provide the most reasonable program and give necessary illustration till accordant with customer.

3. Through negotiation, technical engineer can be sent to scene for layout for customer.

Mid-salesof fully-automated flyash/sand aac block production line for customers:

1. Design the technical documents such as whole equipment layout, construction bases layout, equipment installation drawings based on the scene.

2. Produce the equipments strictly as the contract when the customer is doing base construction.

3. Inspection before delivery, shipment organization and customer take-over..

After-sales of fully-automated flyash/sand aac block production line for customers:

1. Technical engineer will be sent to scene for instruction, installation and test run.

2. On-spot training for customer operator after installation and debug.

3. Irregular return visit to customer after normal production begins.

Regarding the fully-automated flyash/sand aac block production line , we can supply all the equipments from 20000cbm3-300000cbm3 with high quality and best service, we have rich experience in installing the fully-automated flyash/sand aac block production line abroad and helping our customers to operate it well.

- Q: To register a main tile, building materials related to the company, which categories to be registered? The

- To register a main tile, building materials related to the company, which categories to be registered? The

- Q: But I feel quite like a wooden floor of the Yeah, it is not really a layer of wood is the bottom of the tile? More

- Mori wood from the inside to the outside are tiles, patterns are high-tech means engraved on the brick surface, and because after the digital film for the compensation, The same logs. But it is not a wooden floor so no formaldehyde.

- Q: Hello, I have a bead curtain, bead curtain fixed in a plastic sliver above, I want this note fixed on the tile above, with the "brother two good" glue, but a few days to die, down The The I would like to ask you what is a good way to frighten the feces to drink tea evaluation Taizhou Kusheng it? What material? Do not want to set nails, white blind brick, thank you, more

- With tiles, "tiles" is used as an indispensable decoration material for home decoration. It is made of polymer and other cement-based adhesives. Special formula can be used in almost all kinds of tiles. The use of ceramic tile, so that the kitchen, bathroom decoration has the following advantages: good water retention, easy to produce hollowing; high bond strength, do not fall off; reduce the building load, from the traditional paving per square meter of cement 11 ~ 18KG to reduce the amount of ceramic tile to 4 ~ 5KG, thereby reducing the building settlement and cracking; tile adhesive coating thickness is much smaller than the traditional cement, saving valuable space position; site construction environment clean; Barrels can be mixed materials; tile adhesive construction is very convenient; no need to immerse brick wet wall;

- Q: How to tile building materials industry manager set sales tasks, commission and how to set?

- Whether there are old people, children live together you, we know that children are more sedentary, and the elderly is hard to say afraid of falling tiles, this view is wrong, rigid and more tiles

- Q: To "goodbye a chome" to ask: clay brick or clay brick

- But in detail that there are some differences

- Q: Is the old house, about less than 2 square meters, mainly put the child valve powder mixed with america stumbler overflowing a space for the washing machine. Now is the cement floor, but also relatively old, the above is not very clean, would like to shop on the floor, what materials and tools? Detailed list and usage. What do I need to do? More

- Such as the net height of the room, the general net height of more than 3 meters is possible. But in order to strengthen the adhesion of the new pavement tiles to prevent the future of its empty layer, from the drums of the situation, should be in the original brick with coarse sand or small melon stone stone foundation leveling, the thickness should be 6cm the above. Methods and construction steps: . roughly to the original turn to the hair (the original tiles broken, broken) . clean up the venue. Water rinse the ground later the effect of better . with a roving or small pieces of concrete will be pouring and leveling the ground, can also be a layer of special floor wire buried in the concrete under . to be dry 8 minutes, the general .2 Days after the normal floor tiles can be completed above the ground floor height will increase by 11 cm or so, this will rarely produce construction waste, but the longer duration is not economical. Can also be the original old tiles to play after the laying of new tiles, most of the home decoration using this method, this construction movement, and produce a lot of construction waste. To sum up, it is recommended to choose the appropriate construction method according to the situation of the net height of the house and the house.

- Q: And please explain whether the various tests of shale brick fire test, whether it can be issued an experimental report Thank you. Thank you! More

- All the steel smelting all refractory materials, can not find shale brick, is not used as insulation materials ah

- Q: Taking into account the use of environmental protection and practical use of red wood

- Imitation wood grain brick why this red: imitation wood grain brick PK wood floor use advantages imitation wood such as wood wins wood low price long imitation wood grain tiles relative to ordinary high tiles, but with hundreds of square meters of solid wood Compared to the floor, the wood grain brick obviously has a great price advantage, and wood grain brick long life, wear, no need to like wood products as a regular waxing maintenance, low cost long use, is indeed more cost-effective s Choice The use of space to expand the style of texture selection of multi-grain brick can be used in the wood flooring inconvenient use of the kitchen, bathroom space, no doubt added to the practicality; in the category, imitation wood grain brick with porcelain glazed, glazed matte, glazed Semi-polished, glazed all polished, flat / convex surface, etc, different processes to create a different texture; with a variety of patterns, shapes and colors, consumers in the style and texture of choice, more wood flooring is also more abundant Wear and waterproof cleaning and maintenance simple and easy to imitate wood surface brick surface by the waterproof treatment, if dust contaminated, can be directly wipe with water, while imitation wood brick also has strong anti-fouling ability, under normal circumstances, water and standard neutral detergent You can complete the cleaning, cleaning and maintenance than wood flooring a lot easier Fire-free formaldehyde environmental safety and safe use of intelligent imitation wood brick itself with fire-retardant fire, corrosion-resistant features, and to avoid the possibility of formaldehyde in the wood floor, green, environmentally friendly building materials, while the ordinary brick tiles Slip performance is good, home children and elderly walking is relatively safe

- Q: Inside the wall to buy skills to identify brand skills is more important

- Inside the wall is currently on the market in the high frequency, the vast majority of consumers in the purchase of the brand-based, for a strange field we can only look from the public to start the brand

- Q: What is the benefit of brick materials compared to other materials? I was learning the building, the teacher called analysis of building materials, I chose the building is all red brick.

- What type of building is it? Now the state is limited to the use of red brick, waste of clay resources, not environmentally friendly. Many areas are not allowed to be a solid sticky spy spy swift slanting slanting rivet tiles for civilian buildings, if it is ordinary residential, office buildings and the like, it is recommended that you still change the frame structure, with hollow brick or concrete Block.

1. Manufacturer Overview

| Location | Henan,China (Mainland) |

| Year Established | 2011 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | 40.00% Southeast Asia 30.00% Domestic Market 20.00% Eastern Europe 10.00% Africa |

| Company Certifications | NQA Quality certification |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao,Tianjin,Shanghai |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese, Spanish, Japanese, French, Russian, Italian |

| b) Factory Information | |

| Factory Size: | 3,000-5,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fully Automated Flyash/Sand AAC Block Production Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches