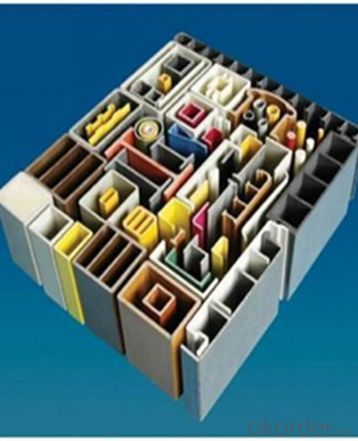

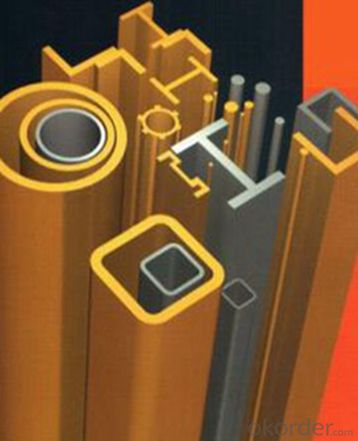

FRP Pultrusion Profiles - Lightweight & High-Quality FRP Pultruded Grating with Noxious Resistance in Various Styles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRODUCT DESCRIPTION

Pultruded grating is made by a particular assembly process, which using “I” shape as its main load-bearing and special rod to go through the bearing bar. Pultruded grating include the standard grating and the custom grating, the custom grating can be designed to meet customer’s requirement or special using condition by changing the shape, size and space of the bearing bars, the surface can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

FRP pultruded grating has the most characteristics of molded grating, but it has its distinct advantages, it has very high fiberglass content in the loading direction, so it has very high load capability, it has more superiority when used at wide span, so that the basic support will be decreased and the project cost will be reduced accordingly.

SPECIFICATION

The standard space between two crossbars is 6 inch or 12 inch.

Thickness (mm) | Bar width (mm) | Open space (mm) | Open rate (%) | Approx weight (kg/m |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

CHOICE FOR PULTRUDED GRATING

Resin: GP resin, ISO resin, VE resin, Phenol resin

Color choice: Yellow, gray, green, custom color

Surface choice: Groove surface, grit surface, lozenge cover surface

FEATURES

a. Anti-corrosion and anti-rust

b. Light weight and high strength

c. Anti-flammable

d. Anti- fatigue

e. Safe and anti-slippery

f. Anti-ageing

FIELDS SERVED

Sewage treatment,

water supply and drainage,

chemical industry,

oil industry,

power engineering,

pulp and paper,

construction engineering,

spinning, marine engineering.

APPLICATION

Operation terrace,

stair walkway,

ground floor,

trench cover,

sidewalk.

COMPANT DESCRIPTION

CNBM,China National Building Materials Group is a state-owned enterprise in charge of administrative affairs in china building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products,professional service and complete solution to our customers. Strong delivery capacity, advanced technology& management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

FAQ

Q1.What's your sample policy?

A:We can supply the sample if we have ready parts in stock, but the customers have to pay the courier cost.

Q2.Can you produce according to the samples?

A: Yes, we can produce or modify the products according to your request.

Q3.How do you deliver the goods to my country?

A:We can provide international express, such as DHL, EMS, UPS, FedEx, etc. We select air freight and sea freight upon your requests. Quotations if without mentioning the shipping costs are shipping fee excluded.

Q4.How much does it cost to ship to my country?

A:When you goanna to place an order, please contact us, because different country has different freight.

Q5.How to get the catalogue?

A:please contact us and tell us what you are looking for.

We will try our best to meet customers' demands. Welcome you come here to visit us. We sincerely welcome partners around the world to establish business cooperation with us on the basis of mutual trust, benefit and development.

PICTURES

- Q: Are FRP pultrusion profiles resistant to alkalis?

- FRP pultrusion profiles are generally able to resist alkalis. This is because FRP composites are materials made of a polymer matrix reinforced with fibers like glass or carbon. The polymer matrix in FRP pultrusion profiles has excellent resistance to alkalis, making them suitable for use in places where alkalis are present, such as chemical processing plants, wastewater treatment facilities, or marine structures. However, the resistance of FRP pultrusion profiles to alkalis may vary depending on factors like the type of polymer resin used and the concentration and temperature of the alkali solution. Therefore, it is important to refer to the manufacturer's specifications or perform specific tests to ensure that FRP pultrusion profiles are compatible with the intended alkali environment.

- Q: Are FRP pultrusion profiles resistant to wear or abrasion?

- Yes, FRP pultrusion profiles are highly resistant to wear and abrasion. The combination of strong reinforcing fibers and a durable resin matrix makes them capable of withstanding harsh conditions and maintaining their structural integrity over time, even in high-stress environments. This resistance to wear and abrasion makes FRP pultrusion profiles an excellent choice for applications that require long-lasting and low-maintenance solutions.

- Q: Can FRP pultrusion profiles be used in agricultural applications?

- Yes, FRP pultrusion profiles can be used in agricultural applications. FRP (Fiber Reinforced Polymer) pultrusion profiles are known for their high strength-to-weight ratio, corrosion resistance, and durability, making them suitable for various agricultural applications. One common use of FRP pultrusion profiles in agriculture is in the construction of livestock enclosures such as fences, gates, and pens. These profiles offer excellent resistance to weathering, chemicals, and UV degradation, ensuring long-lasting performance in outdoor environments. Additionally, their lightweight nature makes them easy to handle and install. FRP pultrusion profiles are also used in the manufacturing of agricultural equipment and machinery. They can be utilized for structural components, such as beams and supports, as well as for functional parts like handles, brackets, and covers. The high strength of FRP profiles allows them to withstand heavy loads and harsh operating conditions, while their corrosion resistance ensures longevity in corrosive environments such as fertilizer storage areas or livestock waste management systems. Furthermore, FRP pultrusion profiles can be used for irrigation systems in agriculture. Their non-conductive nature makes them ideal for applications where electrical insulation is required, such as in the construction of irrigation pipes or channels. Additionally, the corrosion resistance of FRP profiles ensures that they can withstand exposure to water, chemicals, and fertilizers commonly used in agricultural irrigation. In summary, FRP pultrusion profiles are well-suited for agricultural applications due to their high strength, corrosion resistance, and durability. Whether it is for livestock enclosures, agricultural machinery, or irrigation systems, FRP profiles offer several advantages that make them a reliable choice in the agricultural industry.

- Q: What are pultrusion materials used for?

- Various sections of Glass Fiber Reinforced Plastic Pultruded sections can be produced with different sections of the die. The profile has the characteristics of high strength, corrosion resistance and light weight

- Q: Are FRP pultrusion profiles suitable for the manufacturing of chemical pumps?

- Yes, FRP pultrusion profiles are suitable for the manufacturing of chemical pumps. FRP (Fiber Reinforced Polymer) pultrusion profiles offer several advantages that make them ideal for use in chemical pump manufacturing. Firstly, FRP pultrusion profiles are highly corrosion-resistant. Chemical pumps are frequently exposed to corrosive chemicals, which can cause damage and deterioration to traditional metal pump components. However, FRP pultrusion profiles are made from a combination of fiber reinforcements and a polymer resin matrix, which makes them highly resistant to corrosion from various chemicals. This makes FRP pultrusion profiles an excellent choice for ensuring the longevity and durability of chemical pumps. Secondly, FRP pultrusion profiles have excellent mechanical properties. They have a high strength-to-weight ratio, which means they can withstand high pressures and loads without adding significant weight to the pump. This is important for chemical pumps that need to handle heavy-duty applications and maintain their performance over time. Additionally, FRP pultrusion profiles offer design flexibility. They can be manufactured in various shapes and sizes, allowing for customized designs that meet specific pump requirements. This versatility in design enables manufacturers to optimize the pump performance and efficiency. Moreover, FRP pultrusion profiles are electrically non-conductive. This is particularly advantageous in chemical pump applications, where the presence of electricity can pose a safety risk. By using FRP pultrusion profiles, the risk of electrical accidents is minimized, ensuring a safer working environment. In summary, FRP pultrusion profiles are well-suited for the manufacturing of chemical pumps. Their corrosion resistance, excellent mechanical properties, design flexibility, and electrical non-conductivity make them a reliable and efficient choice for ensuring the performance, durability, and safety of chemical pumps in various industrial applications.

- Q: Are FRP pultrusion profiles suitable for the manufacturing of antenna masts?

- Yes, FRP pultrusion profiles are suitable for the manufacturing of antenna masts. FRP pultrusion profiles offer several advantages such as high strength-to-weight ratio, corrosion resistance, and excellent electrical insulation properties. These characteristics make them ideal for antenna mast construction, as they can withstand various environmental conditions and provide reliable support for antennas.

- Q: Can FRP pultrusion profiles be used in the construction of outdoor signage?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of outdoor signage. FRP pultrusion profiles have excellent durability and resistance to weathering, making them suitable for outdoor applications. They are lightweight, corrosion-resistant, and can be customized into various shapes and sizes, making them ideal for signage purposes. Additionally, FRP pultrusion profiles offer high strength-to-weight ratio and can withstand harsh environmental conditions, ensuring long-lasting and reliable outdoor signage.

- Q: Are FRP pultrusion profiles non-conductive?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are non-conductive. This is because they are made up of a combination of reinforced fibers, typically fiberglass, and a polymer resin matrix. The fiberglass fibers provide the strength and stiffness, while the polymer resin acts as a binder to hold the fibers together. One of the key advantages of FRP pultrusion profiles is their excellent electrical insulation properties. Unlike metals, which are conductive, FRP profiles do not conduct electricity. This makes them ideal for applications where electrical insulation is required. In addition to being non-conductive, FRP pultrusion profiles also offer other benefits such as corrosion resistance, high strength-to-weight ratio, and low maintenance requirements. These properties make them suitable for a wide range of applications, including electrical and telecom infrastructure, chemical processing plants, bridges, and building construction. It is important to note that the non-conductive nature of FRP pultrusion profiles does not mean they cannot be made conductive if required. Special additives or coatings can be incorporated during the manufacturing process to impart conductive properties if needed.

- Q: Can FRP pultrusion profiles be used in the construction industry?

- Indeed, the construction industry can utilize FRP (Fiber Reinforced Polymer) pultrusion profiles. These profiles offer numerous benefits that make them appropriate for diverse construction applications. To begin with, FRP pultrusion profiles possess exceptional strength while remaining lightweight. Consequently, they are an excellent choice for construction projects as they provide a high strength-to-weight ratio. This reduces the overall weight of the structure while preserving its structural integrity. This advantage is particularly valuable for applications like bridges, walkways, and platforms. Furthermore, FRP pultrusion profiles exhibit a high level of resistance to corrosion. Unlike conventional construction materials such as steel or wood, FRP does not rust, rot, or corrode when exposed to harsh environmental conditions, chemicals, or moisture. Consequently, FRP profiles are ideal for outdoor or marine applications where corrosion can be a concern, such as seawalls, docks, or offshore structures. In addition, FRP pultrusion profiles possess excellent electrical and thermal insulation properties. This makes them suitable for applications where minimizing electrical conductivity is necessary, such as electrical enclosures or cable trays. Moreover, FRP profiles have low thermal conductivity, which enhances energy efficiency in buildings by reducing heat transfer. Furthermore, FRP pultrusion profiles are highly durable and require minimal maintenance. They boast a long service life and do not necessitate regular painting, sealing, or treatment like traditional materials. Consequently, significant cost savings can be achieved throughout the life cycle of a construction project. Lastly, FRP pultrusion profiles can be customized to meet specific strength, stiffness, and dimensional requirements. They can be produced in various shapes, sizes, and colors, allowing for flexibility in design. This versatility renders FRP profiles suitable for a wide range of construction applications, including beams, columns, gratings, handrails, and structural components. To summarize, FRP pultrusion profiles are a viable choice for the construction industry due to their lightweight nature, high strength, corrosion resistance, electrical and thermal insulation properties, durability, low maintenance requirements, and design flexibility.

- Q: Can FRP pultrusion profiles be used in the construction of pedestrian bridges?

- Pedestrian bridges can utilize FRP pultrusion profiles, which offer numerous advantages for bridge construction. Firstly, these profiles are lightweight yet incredibly strong and durable, making them ideal for weight-sensitive pedestrian bridges. The lightweight nature of FRP profiles also simplifies transportation and installation, resulting in cost savings. Secondly, FRP pultrusion profiles are corrosion-resistant, a critical factor in bridge construction. Unlike traditional materials such as steel or concrete, FRP does not rust or corrode, even in harsh environments. This property significantly prolongs the lifespan of pedestrian bridges while reducing maintenance costs. Moreover, FRP pultrusion profiles provide design flexibility. They can easily be tailored to meet specific project requirements, allowing for the creation of unique and innovative bridge designs. The material can be molded into various shapes and sizes, enabling the construction of aesthetically pleasing pedestrian bridges. Furthermore, FRP pultrusion profiles possess excellent mechanical properties, including a high strength-to-weight ratio and fatigue resistance. This ensures that the bridge can withstand the loads and stresses imposed by pedestrian traffic over an extended period. Lastly, FRP pultrusion profiles are non-conductive, making them a safe choice for pedestrian bridges. In areas where there are overhead power lines or electrical equipment, the non-conductive nature of FRP reduces the risk of electrical accidents. In conclusion, FRP pultrusion profiles are a suitable option for constructing pedestrian bridges due to their lightweight, corrosion-resistant, customizable, and mechanically strong properties. Their usage can result in durable, low-maintenance, and visually appealing bridges that provide a safe and efficient means of pedestrian transportation.

Send your message to us

FRP Pultrusion Profiles - Lightweight & High-Quality FRP Pultruded Grating with Noxious Resistance in Various Styles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords