Composite Pipes - FRP Process Pipe / High Pressure FRP Pipe Round Tubes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of FRP Process Pipe Description

We offer FRP standard and non-conventional profiles manufactured from various class of matrix resin like ethylene type, high inflaming retarding ethylene type,ISO resin type,No-Poison resin type,ORP resin typeand fiberglass,and of fiberglass like E-Roving M-Roving,which result in the profiles are applied in different performance required,offering a unique combination of chemical resistance, size stability, high strength, and thermal/electric non-conductivity.

2. Main Features of FRP Process Pipe

1) High Pressure FRP Pipe export

2) Corrosion resistant,longlife

3) Covenient and quick install

4) ISO9001

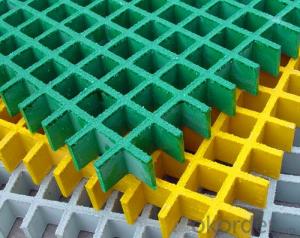

3. FRP Process Pipe Images

4. FRP Process Pipe Specification

1)Small specific gravity, light weight: FRP pipe’s specific gravity is 1.65-2.0 and one 1/4 compared with steel; hoop flexible tensile strength for FRP pipe is 150-420 MPa and axis tensile strength is 60-150MPa, similar to alloy steel. FRP pipe’s strength/specific gravity is 2 or 3 times compared with alloy steel so it can be designed according to customers different requirements for various pips bearing inside and outside pressure. For the same diameter pipe, FRP pipe’s weight is 1/2.5 compared with carbon steel pipe, 1/3.5 compared with cast iron pip, 1/8 compared with reinforced concrete pipe, so it’s easy for construction and transporting.

2) Fewer joints and efficient installment: Usual pipe’s length is 4-12 meters(other special length is also available according to customer demands). Single pipe is long with few joints to accelerate installment speed and reduce the fault possibility then improve efficiency of quality of construction of whole pipe.

5. FAQ of FRP Process Pipe

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

One of the leading manufacturers and suppliers specializing in FRP pipe products in China. The integrated sales & service ensures customers with various demands an easier access for purchasing management.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: Is the installation of FRP pipes required qualification?

- Generally speaking, the glass steel pipe manufacturers will be installed for shipyard workers training, but if the shipyard did not ask, the training goal is to allow workers to master the skills to install, but they do not grant workers qualification certificate, but some shipyard will require workers engaged in installation with the installation qualification, so manufacturers will end in training workers to master confirmation the installation skills of workers, awarded the class approved qualification certificate. I don't know. Are you clear about that?.

- Q: Why FRP pipe corrosion?

- If it is ordinary water, generally does not count corrosion, there will be no obvious corrosion, long time began to soak rotten.

- Q: Is it useful to make gas pipelines with glass steel pipes? Or the idea that the technology is mature?

- I don't think it's enough, because the strength of FRP is not enough, it can easily be brittle and easily perforated in the field for a long time!

- Q: Glass fiber reinforced plastic GRE pipe broken hole how to repair and repair?

- Resin selection of good points, the general also line, as well as accelerators, curing agents, high-quality glass fiber cloth.

- Q: Raw material and mix ratio of inorganic glass fibre reinforced plastic wind pipe

- The general ratio is 1 to 0.001

- Q: What is the heat preservation of the plumbing pipe now? I'd like to use fiberglass Seek help from a master

- I think that you can use magnesium aluminum silicate pipe because this product is suitable for oil pipeline and pipe insulation insulation general insulation are using the products and for foam asbestos products no pollution of construction

- Q: What is the standard of flange coefficient for FRP ducts?

- That quota said: glass steel duct, pipe fittings, flange and reinforcing frame are in accordance with the finished preparation, only the wind pipe and the valve flange connection, before the implementation of the equipment support within the 20kg section, multiplied by the coefficient 1.4. Glass fiber reinforced plastic wind pipe is finished product: when it is made, there are moulds. According to the design of the drawing, the mould is made. The flange and the air duct are one! Remove the mold and install the hole on the flange! In general negotiations with the manufacturers directly n yuan / square meter (production, installation), whether it involves the number of flanges, such as included, there is no need to re count, direct calculation of the inner diameter of the air duct is the expansion area!

- Q: What epoxy resin is used for anticorrosion of pipeline glass fiber reinforced plastics?

- 3PE has been anti-corrosion principle, there is no need for anti-corrosion, but now the domestic situation. Directional drilling pipe cannot be detected and repaired, the anticorrosion layer cannot have serious damage to the pipeline, long-term safety operation, it should be required for coating directional drilling: scratch resistance, abrasion resistance, impact resistance, high hardness, strong adhesion and pipeline, corrosion resistance, water resistance have a good soak, matching and cathodic protection system.

- Q: What kind of epoxy resin and formula do you need for making fiberglass pipe?

- This data mainly explains glass fiber reinforced plastics and other glass fiber reinforced materials manual forming process and all kinds of products.

- Q: What are FRP pipes used for making? What raw materials?

- Reinforced plastic made of glass fiber or its products as reinforcing material. Entitled "glass fiber reinforced plastics" or "glass fiber reinforced plastics". Because of the different kinds of resins used, they are called polyester glass fiber reinforced plastics, epoxy glass fiber reinforced plastics and phenolic resin glass fiber reinforced plastics. Glass has a hard and brittle, has a good transparency and high temperature resistance, corrosion resistance and other properties; at the same time, steel is very hard and not brittle, but also has high temperature resistance characteristics.

Send your message to us

Composite Pipes - FRP Process Pipe / High Pressure FRP Pipe Round Tubes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords