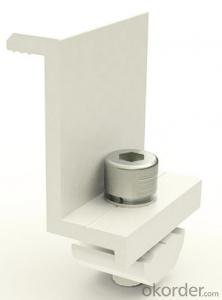

Rail-Less Solar Mounting System - Framed Solar Module Clamps, Solar Racking System Accessory, Solar Panel Mounting Clamps

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Framed Solar Module Clamps, Solar Racking System Accessary, Solar Panel Mounting Clamps

Specifications

Framed Solar Module Clamps:1)ISO 9001,AS/NZS 1170&TUV&MCS certified

2)Fit all kinds of panels

3)Easy Installation

1.Easy Installation. The innovative Gracesolar rail and T-Screw modules have greatly simplified the installation of PV modules.The System can be installed with a single Hexagon Key and standard tool kit.The SolarRoof system is aided by a very high level of pressembly.The T-Screw module and unique rail extension method allow greatly reduced installation times.

2.Great Flexbilitity.With the SolarRoof,frammed photovoltaic modules can be easily mounted on pitched roofs.The SolarRoof system has mounting accessories designed for use on almost every roof cladding available.Excellent Compatibility.Designed as a unversal racking system,framed modules from all the popular manufacturers can be used.

3.High Accuracy. Without the need for onsite cutting,the use of our unique rail extending allows the system to be installed with millimetre accuracy.

4.Excellent Adaptability:The height adjustment of the rails allows a level PV array to be established,no matter how uneven the roof.Engineered To High Standard SolarRoof is made to the highest standard,safe and strong its designed to Comply with AS/NZS 1170.

5.Maximum Lifespan:All components are made of quality extruded aluminium and stainless steel.The high corrosion resistance guarantees the maximun possible lifespan and is also completely recyclable.

6.Guaranteed Durability: a guarantee of 10 years on the durability of all components used.

- Q: Can a solar mounting system be installed on a rooftop with a built-up roof?

- Yes, a solar mounting system can be installed on a rooftop with a built-up roof. The mounting system is designed to be compatible with various roof types, including built-up roofs. Proper installation techniques and considerations for the roof's structural integrity and waterproofing will need to be followed to ensure a successful installation.

- Q: Can a solar mounting system be used on membrane roofs?

- Yes, a solar mounting system can be used on membrane roofs. Membrane roofs, such as TPO or EPDM, provide a suitable surface for installing solar panels. Specialized mounting systems are available that are designed to securely attach solar panels to these types of roofs without compromising their integrity. These systems typically use ballast or adhesive methods to avoid puncturing the roof membrane and ensure a watertight seal.

- Q: Can solar mounting systems be installed on rooftops with rooftop access hatches?

- Yes, solar mounting systems can be installed on rooftops with rooftop access hatches. The mounting systems can be designed and installed in a way that allows for easy access to the rooftop hatches without obstruction. This ensures that the solar panels can be maintained and serviced without any inconvenience.

- Q: Can a solar mounting system be installed on a university or college campus?

- Yes, a solar mounting system can be installed on a university or college campus. In fact, many educational institutions are increasingly embracing renewable energy and installing solar systems as part of their sustainability initiatives. These systems can be mounted on rooftops, parking lots, or open spaces on campus to generate clean and renewable energy, reducing carbon emissions and saving on electricity costs.

- Q: Can a solar mounting system be used with both silicon and thin-film solar panels?

- Yes, a solar mounting system can be used with both silicon and thin-film solar panels. The mounting system is designed to accommodate various types of solar panels, ensuring compatibility and flexibility in installation.

- Q: Can a solar mounting system be used in areas with solar incentives for gyms?

- Yes, a solar mounting system can definitely be used in areas with solar incentives for gyms. These incentives aim to promote the use of renewable energy sources like solar power, and installing a solar mounting system at a gym would be a great way to take advantage of these incentives. It not only helps the gym reduce its carbon footprint and electricity costs but also contributes to the overall sustainability of the community.

- Q: Can a solar mounting system be installed on a remote or off-grid location?

- Yes, a solar mounting system can be installed on a remote or off-grid location. In fact, solar power is particularly beneficial for off-grid locations as it provides a reliable and sustainable source of energy without the need for a traditional power grid connection. The solar mounting system can be designed to withstand the unique challenges of remote locations, such as extreme weather conditions and limited accessibility, ensuring the efficient and uninterrupted operation of the solar panels.

- Q: Can a solar mounting system be used on tile roofs?

- Yes, a solar mounting system can be used on tile roofs. There are specific mounting systems designed to accommodate tile roofs, ensuring a secure and efficient installation of solar panels.

- Q: Can a solar mounting system be used with solar carports?

- Yes, a solar mounting system can be used with solar carports. Solar carports are designed to provide shade for parked vehicles while also generating solar energy. A solar mounting system allows the installation of solar panels on carport structures, enabling them to capture sunlight and convert it into electricity. This integration provides a dual benefit of generating renewable energy and providing covered parking spaces.

- Q: Can a solar mounting system be used in areas with solar incentives for government buildings?

- Yes, a solar mounting system can be used in areas with solar incentives for government buildings. These mounting systems are designed to support solar panels and can be installed on various types of buildings, including government buildings. By utilizing solar incentives offered by the government, such as tax credits or grants, government buildings can benefit from renewable energy generation and reduce their electricity costs.

Send your message to us

Rail-Less Solar Mounting System - Framed Solar Module Clamps, Solar Racking System Accessory, Solar Panel Mounting Clamps

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords