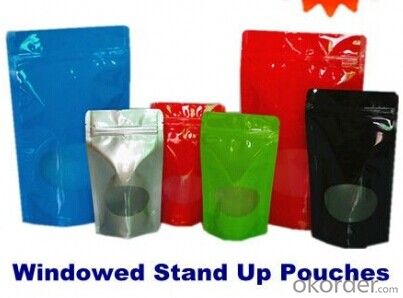

Food Grade Plastic Stand Up Pouch With Window

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 PCS

- Supply Capability:

- 100000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of Food Grade Plastic Stand Up Pouch With Window:

Food Grade Plastic Stand Up Pouch With Window are processing with imported materials,we have introduced advanced equipment and high manufacturing technology into production lines and we have rich experience in producing plastic bag .can meet your needs by fulfilling your specification in a positive manner .High efficiency and speed are our working style .high quality and competitive price are our pursuit.

Food Grade Plastic Stand Up Pouch With Window mainly used for packing food such as coffee, tea, snack, powder etc.

2. Main Features Food Grade Plastic Stand Up Pouch With Window:

Excellent quality control

Experienced facotry produced

SGS passed

3. Food Grade Plastic Stand Up Pouch With Window Photos:

4. Food Grade Plastic Stand Up Pouch With Window Specification:

1. Material: PE,LDPE,HDPE with Craft paper etc

2.Size:10*10000px or Customized

3.Thickness:10-200um

5.FAQ of Food Grade Plastic Stand Up Pouch With Window:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Plastic packing bags can supply you all kind of packing bags you wanted.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Express carton packaging, plastic packaging should be how to deal with?

- For those cartons, environmentalists have their own ways of using them. "The Jingdong loves to use plastic bags, and Amazon and its customers prefer cartons."." Some of the more orderly carton, you can keep as a storage box. You can use the marker pen to write the contents on the carton, then stack it on the bottom of the cupboard to improve the space utilization. For some cartons that cannot be used for the time being, use the tape on the carton to flatten the cartons.

- Q: The vacuum packing bag is sealed. How can I open the zipper?

- The simplest and most effective way is to apply a layer of wax to the surface of the zipper, and use the lubrication of the wax to achieve a smooth effect. With a candle on the surface of the zipper back and forth after wiping, and then from the bottom of the repeated several times, the zipper will be smooth.

- Q: The shelf life of the package usually takes several forms

- Food soft packing materials mainly include polyethylene, polypropylene, polyester, polyamide and other polymer materials. These packing materials show great differences because of their molecular structure, forming process and additives. Therefore, for food manufacturers, choose a suitable packaging for their products is particularly important, otherwise there will be food safety issues.

- Q: What's the packing of the air in the food package?

- Carbonated drinks are mostly filled with carbon dioxide gas CO2, and its own drinks are carbon dioxide ingredients in the majority, with CO2 replacement of the air, but also for the preservation of the product, to ensure the taste, but also improved the shelf life.In addition, some food packaging is filled with a certain proportion of mixed gas, may be O2+CO2+N2, N2+CO2, O2, +CO2. This is also based on the needs of different enterprises, different customers.

- Q: What material is the surface of the packing bag such as instant noodles, pickled mustard tuber, small bread and so on? Why should we add this layer?

- First, it is easy to heat seal, otherwise only aluminum foil can not be sealed;Two, high barrier plastic film preservation effect is also very good, can increase its number of layers, reduce aluminum foil thickness, thereby reducing costs

- Q: What is the difference between LDPE and PE-LD in a package?

- LDPE is low density polyethylene, and PE-LD should be low density polyethylene. Because according to the PE classification, LDPE (low density polyethylene), MDPE (medium density polyethylene), HDPE (high density polyethylene), VLDPE (low density polyethylene), LLDPE (linear low density polyethylene (mPE), metallocene PE). See, "LD" means "low density".

- Q: Dried fish vacuum packaging packing bag can not puncture

- With dried fish, we recommend the use of aluminum foil bag, also can be vacuumized. It has the function of avoiding light and keeping fresh.

- Q: What does "13 silk" in vacuum packing bag mean?

- Silk is a mechanical worker, commonly known as "0.01 millimeters", the workers who have inherited the technology of Shanghai say "silk", and in the north they say "0.01 millimeters" as "Dao".

- Q: What ink is the food packing bag printed on?

- Because of this, benzene soluble chlorinated polypropylene ink has been gradually eliminated, and in Europe and other developed countries have gradually introduced or banned the use of benzene soluble chlorinated polypropylene ink laws and regulations.

- Q: What can be easily removed from the words printed on plastic bags?

- Plastic packaging is printed on the word if it is ordinary ink with thinner a wipe off, is not easy to erase the organic dye. Such dyes are colored substances. But a coloured substance is not necessarily a dye. What kind of dyes do you use on plastic bags?.

Send your message to us

Food Grade Plastic Stand Up Pouch With Window

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 PCS

- Supply Capability:

- 100000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords