Flexible FRP Auto Pultrusion Machinery with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 32 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Flexible FRP Auto Pultrusion Machinery with High Quality

Product Description:

This system consist of yarn frame,mat frame,impregnation tank,mould heatingand clamping device,traction machine and cutting machine.

Pultrusion process is put the impregnation fiberglass.yarn,mat and other strength material,from the traction to through the mould heating,pultrusion,curing,then continuous to produce into the difference FRP profiles.

Main Characteristic:

1. The machine is designed according to the big section profile, with the features of strong traction force; it is steadily to operate;

2. Traction gantry makes ordered according to requested length.

3.Using function: it have single and double manually operated gantry and double gantry automatic reciprocating running function.

Product Parameters:

Name | Flexible FRP Auto Pultrusion Machinery with High Quality |

Product | FRP Pultrusion Machine |

Brand | CMAX |

Size | Customized |

Color | White |

Delivery | 30-45Days |

Material | PP |

Technique | Pultrusion |

Warranty | 1 Year |

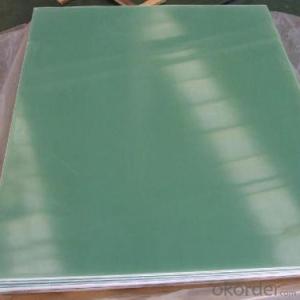

Pictures:

FAQ:

Q1: What is the Warranty for the this products?

A1: For the product ,we have 1years warranty.If any quality problems on our side occured in this period ,we will take on the shipping cost and replacement.

Q2: How Do I know that the product that you offer is good in Mechanical Properties?

A2: Before order ,we will give you a free sample attached with a free strength report test by our engineers.

Q3: What color of the products that you can offer ?

A3: We offer any color of the product that you prefer.

Q4: Do you Accepted Small Quantity Order ,what is the MOQ for the profiles ?

A4: Yes, we Accepted small quantity.

Q5:What Is Our Normal Payments Terms?

A5:Our normal payment terms now is: T/T, L/C or western union,paypal

- Q: Which kind of engineering plastics can be machined on machine tools?

- Nylon, POM, organic glass, textolite etc can be processed on the machine.

- Q: I need to know where to buy the equipment and what I need to do

- PVC fiber reinforced hose machine is suitable for the plastic flexible pipe, provide first-class service characteristics of pressure liquid conveying water Henan Anyang HuaSu Machinery Manufacturing Co. Ltd. fly for you: the best quality, best price. High output and low power consumption

- Q: What kind of equipment does the plastic bottle crush processing plant need?

- Plastic bottle initial processing, with crusher or broken cleaning machine, sheet cleaning machine, dryer

- Q: How much does it cost to run a small waste plastics processing plant?

- Hello, you need to tell me in which city and set up factories in general a small waste plastic particles Factory granulation machine and rolling machine related maintenance tools almost one hundred and twenty thousand or so this is the lowest level for the continuous operation of the workers to four hundred pounds or twenty total count down several flat covering but the mechanical and artificial need not one hundred and eighty thousand factory covers an area of such the words of small plastic granulation plant can take 25

- Q: What plastic products do you have and what's the use of it?

- Industry: Electrical and electric industry in making extensive use of plastic insulating materials and packaging materials;

- Q: from raw material to particle forming, need several devices, what are they? _?

- I also want to open such a factory, does the profit? I'm using scrap plastic as a particle here, so I want to check it out.

- Q: The main plastic of plastic products

- Polyethylene plastics (Polyethylene) are polymers of ethylene monomers. The raw material for production is oil, coke oven gas or alcohol. Industrial production of polyethylene usually by ethanol dehydration, acetylene catalytic hydrogenation or high temperature cracking. Its commodity name is abbreviated as "B plastic"; the English abbreviation is "PE". Because the density of polyethylene is different, it is divided into low-density polyethylene.[PE (L)], medium density polyethylene [PE (M)] and high density polyethylene [PE (H)].The molecular formula of polyethylene is: (- CH2, CH2 -) n. It is linear in geometry and theoretically has no branched chain and is prone to crystallization. Usually the polyethylene molecule is composed of crystalline and amorphous state in high elastic interlaced region; crystalline polyethylene plastic gives high hardness, strength, chemical stability; amorphous region with polyethylene plastic higher flexibility, toughness, transparency etc.. In fact, polyethylene macromolecules are not absolutely free of branched chains. Its crystallinity is different, density is different, physical and mechanical properties are also different.

- Q: I found that the plastic bags and food bags used in the county town of my work are from abroad. I would like to open a plastic bag processing plant. What kind of machines do I need?. How much is it (cheaper, smaller per day)?. Where does the raw material go in?. The main market for vegetables; small bags for small food. Who will answer in detail?. Thank you

- Recommended Xiangxi inspection, old plastic easy to do, but have no production, proposed to do environmental protection cloth generation.

- Q: How can we deal with the pollution of waste plastic particles?

- According to the Huacheng machinery senior experts, the current problems like water plastic particles in the machining process can be improved through the method of building see sedimentation tank, water can be reused. The odor problem Huacheng machinery experts tell us, within the industry there is a technique to dispose of smoke and smell. This is a great progress of waste plastics recycling industry.To solve the difficult problem of plastic pollution in the process of granulation, you can be more assured of practitioners engaged in processing. Through investigations now waste plastic particles of the market space is still very great development prospect is good.

- Q: Where are home plastic products, plastic products for daily use, plastic products processing, plastic products, mold

- You are looking for people to give you the processing mold, is it, then you go to the hook online to find ah, above doing this factory a lot

Send your message to us

Flexible FRP Auto Pultrusion Machinery with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 32 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords