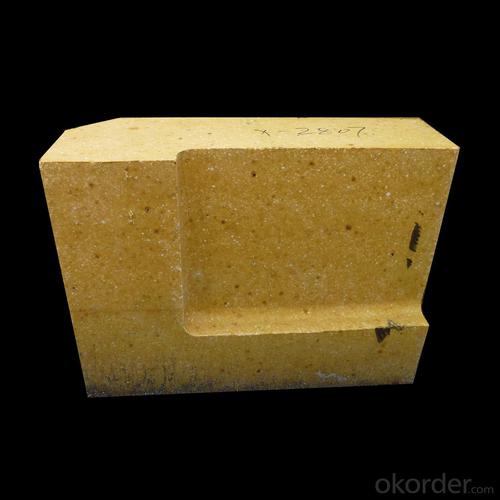

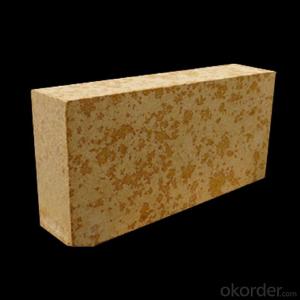

Fireclay Brick - High Strength S96 Refractory Silica Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SILICA BRICK S-96 for Hot-Blast Stoves

CMAX Silica bricks are made from high quality quartz tail sand, lime and mineralizing agent through the process of crashing, screening, mixing, pressing, drying and sintering.

Application

CMAX Silica bricks are commonly applied in coke oven, hot blast stoves, glass furnace etc.

Features

High refractoriness under load

High mechanical strength

Excellent thermal shock resistance

Corrosion resistance.

Good resistance against acid slag

High mechanical strength

Stable performance under high temperature environment

CMAX Silica bricks are made from high quality quartz tail sand, lime and minaralizing agent through the process of crashing, screening, mixing, pressing, drying and sintering.

- Q: What is the specific heat of a refractory bricks (clay)?

- Approximately it's about 2000; M3 specific heat is wrong with this argument, two degree clay is 1730 degrees, three degree clay is 1690 degrees, clay bricks are mixture, bulk density, 1900KG/, only elementary substance has specific heat refractoriness.

- Q: High alumina refractory bricks (Universal arc) weight for hot metal ladle

- Climbing, C23B ladle generally use T3 ladle bottom brick, brick wall with C23 package, C231 Some permanent layers are built from high alumina bricks, and some are built from castable refractory, T82, T43. Specific size can be checked according to the type of brick

- Q: How can refractory bricks be punched?

- Electric is ok

- Q: In tunnel kiln, what is the meaning of refractory proportion 2.0?

- The proportion of refractory bricks is related to the density.

- Q: How many pieces of porous brick is equal to one ton?

- Refractory bricks are generally classified into two types, that is, shapeless refractory materials and shaped refractory materials. Shapeless refractory material: Also known as castable refractory, is hybrid power material composed of a variety of aggregate or a kind of aggregate and one or more kinds of the mixture of adhesive particles, it should be used evenly mixed with one or more kinds of the liquid, which has strong liquidity. Shaped refractory material: The general making of firebrick, there are standard rules for the shape, can also temporarily process according to need of building and cutting. The following are the specifications. fireclay bricks 230*114*65 each block 3.0 - 3.6 kg; special-shaped fireclay brick 230*65/55*114 each block 2.8 - 3.3 kg; the reason for the weight's ranges is that because the quality is different, in general, heavy density, good quality!

- Q: Do refractory bricks insulate heat?

- Refractory bricks have a certain ability of heat insulation, but its thermal insulation is far less than that of glass fiber and wool.

- Q: With what three clay brick clay brick with six holes under what circumstances?

- Without strict restrictions, the main difference is in the bulk density.

- Q: What's the difference between fired clay bricks and sintered porous bricks?

- Clay, shale, coal gangue or fly ash as the main raw material, calcined by the hole rate of not less than 25%, the size of the hole is small and large number, mainly used for load-bearing parts of the brick, referred to as porous brick. At present, sintered porous bricks are divided into two types of P bricks and M bricks. As compared with ordinary clay bricks, sintered porous bricks have higher compressive strength, corrosion resistance and durability, as well as light weight and good thermal insulation performance. Sintered porous bricks can be widely used in load-bearing walls of industrial and civil buildings.

- Q: How many bricks, mortar and how much wear and tear does one side of the clay brick masonry need?

- The loss rate of mortar is 1%, so the total consumption of mortar is 0.212M3*1.01=0.214M3

- Q: What kind of refractory material is used in the furnace when the boiler reaches more than 1200 degrees?

- except refractory brick, refractories include refractory concrete (refractory cement+aggregate), fire-resistant insulating layer (refractory cement+vermiculite powder or refractory cement + diatomaceous earth) and so on.

Send your message to us

Fireclay Brick - High Strength S96 Refractory Silica Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords