Fireclay Brick - High Resistance to Thermal Shock

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 10000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

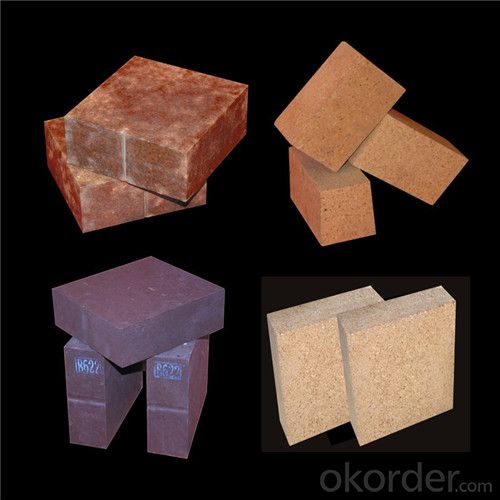

General Information of Fireclay Bricks

CMAX fireclay bricks are made from clinker clay. The alumina content ranges from 36% to 48%.

Image of Fireclay Bricks

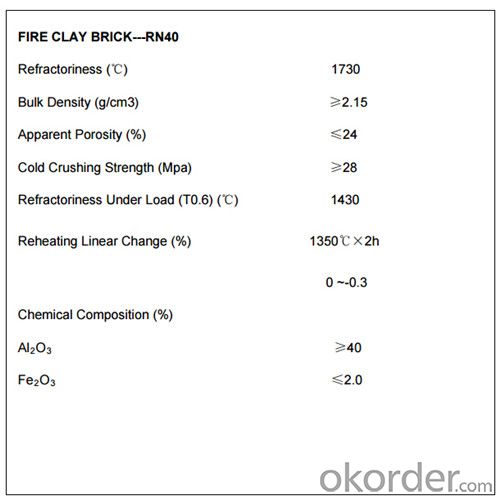

Technical Data of Fireclay Bricks

Feature of Fireclay Bricks

Low thermal conductivity

High refractoriness

High mechanical strength

Excellent thermal shock resistance

Application of Fireclay Bricks

CMAX fireclay bricks are commonly applied in blast furnace, hot blast furnace, teeming ladle, glass furnace, etc.

Why Choose Us

l We are a government owned company with ISO certificate.

l We are listed in Global Fortune 500 with D & B report.

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervis

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such us U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q: does furnace use refractory cement to make refractory bricks?

- You can use fireclay, refractory cement is commonly used to arch. fireclay has good viscidity, it is handy to use.

- Q: what is consequence of high load and soft low of high alumina refractory brick ?

- softening, if not up to the design requirements, may cause vicious incident like the collapse of the stove in use. the full name is softening temperature under a fixed load, as the name suggests, it is the softening temperature after adding the load.

- Q: Expansion ratio of light corundum fireproofing brick

- And then the appropriate drying, the using temperature 1500~1700 degrees of light corundum brick, the porosity is 70% to 80% Now, use foaming method to produce light corundum brick, 3g/, shaped idiosome with mould dry for 4 days in 60 degree to 70 degree oast, it will demoulding, foaming method and evaporating method produce light corundum brick, the thermal conductivity is 0. the containing of AL203 has difference, the corundum brick that use corundum hollow?sphere to produce contain the highest AL203 Finished light corundum brick don't have accurate shape and size after firing.8 1, so products need mechanical or manual cutting after the kiln, finally, firing in 1300 degree and 1550 degree, basically still meters with water forming, just add to burn: 50~60h, because its production methods and the introduction of additives are different, the total sintering time.17W/, light corundum fireproofing brick can be made into density is 0, withstand voltage strength is 4MPa, the containing of A1203 is no more than 99%.

- Q: Are sintered brick concrete bricks?

- Fired bricks are not concrete bricks.According to the different production process of bricks into sintered brick and non sintered brick. Sintered brick in China has more than two thousand years of history, is still a very wide range of wall materials.

- Q: Can common cement mortar be used to build the lining of chimney refractory brick?

- No. You have used fire bricks, which shows there is a certain temperature inside, you'd better use refractory cement

- Q: Would you please tell me how to use the simple method to identify shale brick, clay brick?

- Is the shale as raw material for high temperature baked bricks using shale and coal gangue, clay brick not dense surface, general clay brick for load-bearing structure, relatively thick, single shape; shale brick shapes, shapes with holes, in non bearing structure.

- Q: What kinds of annealing furnace refractory bricks there are?

- But the energy saving effect is good, but also can use lightwight heat insulating brick, but the price is higher than that of clay brick

- Q: What is the main use of refractory brick?

- Almost all high temperature furnace needs of the needs refractory bricks, such as blast furnace for iron smelting, high temperature differential thermal analyzer also use it, refining furnace, converter for steelmaking, muffle furnace, electric furnace and drying equipment. the uses are wide

- Q: What is the raw material for the production of refractory bricks?

- Mainly Magnesium Oxide, use sodium silicate as a binder.

- Q: Why are clay bricks used when buildings are below zero? Frost heaving, water absorption, or something?

- The clay brick has a certain strength, and has better heat insulation and sound insulation performance, and the interior wall of the winter can not appear condensation phenomenon, and the price is low. Although a variety of new wall materials are emerging, clay bricks will still be used as a main material for masonry work in the future

Send your message to us

Fireclay Brick - High Resistance to Thermal Shock

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 10000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords