Fireclay Brick - Good Price and High Quality MgO-C Brick for Steel Ladle

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Company Profile

CNBM INTERNATIONAL CORPORATION

We are a primary subsidiary of China National Building Material Group Co., Ltd.

CNBM Group is a central government-owned enterprise and a Fortune Global 500 company (Ranking 203th in 2019). It is the largest building material manufacturer and service provider in the world, with 15 publicly-listed companies and over 180,000 employees (2019).

Refractory Technology

Our plant was one of the research institutes on refractory materials in CNBM. It was set up in 2001.

Taking the advantages of combining research,process,marketing and technical service,CNBM supply not only first-class refractory materials but also supply distinctive technical services.

CNBM has been dedicated to expand grow space via resource integration and product diversification.5 subsidiaries has been set up by June,2010.

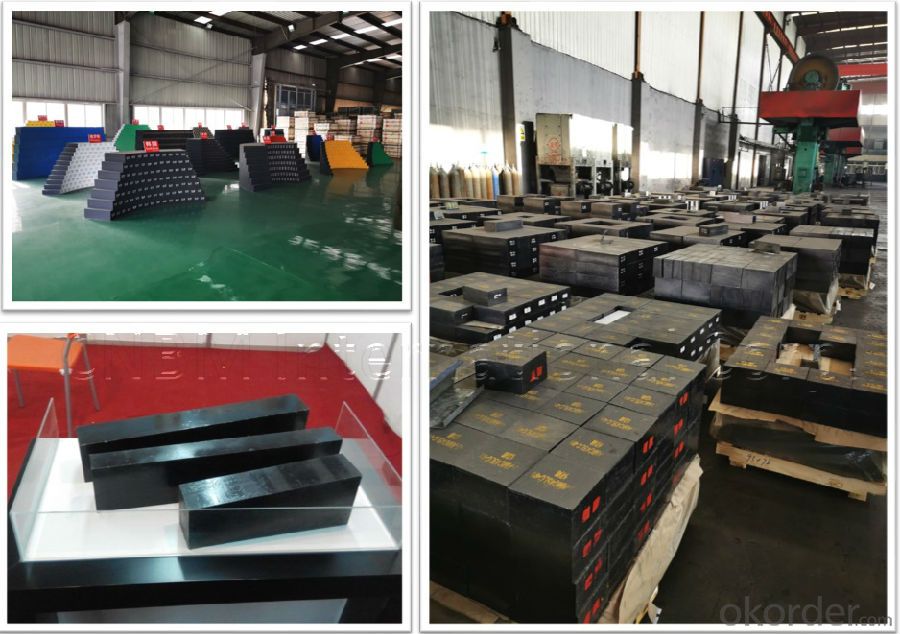

Refractory Plants

·Our annual output is 5000,000 tons per year.

·Our plant are ISO 9001:2008 certificated

·The products cover the refractory area of steel-making, cement, non-ferrous, glass, ceramic and others.

Feature of Magnesia Carbon Brick

Excellent resistance in slag abrasion

Higher temperate resistant with good refractoriness

Lower creep in high temp.

Good thermal shock resistance performance

Lower apparent prosity

not easily wet with slag

Specifications of Magnesia Carbon Brick

MgO and carbon content

Widely used throughout metallurgical industry

Physical And Chemical Indicators For Magnesia Carbon Brick

| Item | MZ-97A | MZ-97B | MZ-95A | MZ95B | MZ-93 | MZ-91 | MZ-89 | DMZ98 | DMZ97 | DMZ96 |

| Density(g/cm3)≥ | 2.96 | 2.96 | 2.94 | 2.94 | 2.94 | 850 | 900 | 3.1 | 3.1 | 3 |

| Cold Crushing Strength (Mpa)≥ | 60 | 60 | 60 | 60 | 60 | 60 | 50 | 90 | 90 | 90 |

| Reheating Linear Change (%) | 1650ºC x 2h 0~ -0.2 | 1650ºC x 2h 0~ -0.3 | 1650ºC x 2h 0~ -0.4 | 1650ºC x 2h 0~ -0.6 | - | - | - | |||

| Refractoriness Under Load(ºC)≥ | 1700 | 1700 | 1650 | 1650 | 1620 | 1560 | 1550 | 1700 | 1700 | 1700 |

| Apparent Porosity (%)≤ | 16 | 18 | 16 | 18 | 18 | 18 | 20 | 14 | 14 | 15 |

| MgO(%) | 97.0 | 96.5 | 95.0 | 94.5 | 93.0 | 91.0 | 89.0 | 97.7 | 97.1 | 96.3 |

| SiO2(%) | 1.0 | 2.0 | 2.0 | 2.0 | 3.5 | - | - | 0.58 | 0.97 | 1.20 |

| CaO(%) | - | - | 2.0 | 2.0 | 2.0 | 3.0 | 3.0 | 0.63 | 0.97 | 1.30 |

| Application | Kiln Linning in Iron and Steel, Copper, Lead, Tin and Zinc Industries | The Tap Hole of Steel Furnace; Tap Hole and Slag Line in Non-Ferrous Industry | ||||||||

Our Services

Free samples are available by freight collect;

Strict QC & Fast delivery

High quality goods, Perfect Pre-sales and after-sales service.

CNBM will update you any production process after placing order.

We have special after-sales team to solve your problem during using our products.

Any question will be get our feedback in the first time.

Packaging & Shipping

Packaging : Packed by sea-worthy wooden pallet + shrink wrapped + carton

For example, Standard size of Fireclay brick : 230X114X65mm

Shipping : 384PCS/plt X 18plts in one 20 feet container;

Proprietary Technology & Patented Products

Refractory technology

All process are conform to ISO9001 quality control systems

(1)The test of raw materials

★For all raw materials, the purchase department should give the test report to the quality supervision department.

(2)The control of production

★Each batch products should be tested

★The quality supervision department should record all test result.

(3)Test Before Production

★Before packing, the quality supervision department should test the chemical content and physical

★Only quality products can be delivery.

★The delivery department should check the package, quantity, name, code, production date, etc.

(4)Quality Traceability Analysis

★Track the products after using and get the feedback of performance.

If customer required, we will give the customer technical solutions and also improve the products.

Damage Mechanism Analysis and Improvement

★ For the maintenance project, CNBM will check the damage condition of the refractory materials in the furnace carefully.

★And then CNBM will give the damage mechanism analysis report to the customer.And CNBM also will provide products improvement solutions to extend the products' service life.

Technical Solution& Construction

★Optimization solutions of the original design to the customer.

★Consultation Service of Refractories Technology

★Technical Staff Training in Refractories Technology

★Specialized Design and Refractories Selection

FAQ

Q:Are you a trading company or manufacturer?

A:CNBM is a large-scale central governmental industrial group with its own manufacturing sector, research and development sector, trading sector and logistics sector.

Q:I have some special requirement about specifications.

A:We have a well-rounded product range, which endows us with the capability of applying many special specifications. Please feel free to contact us with yours.

Q:Do you accept OEM service?

A:Yes, we do.

Q:What is your delivery time?

A:It depends on the size/complexity of your order and our own production schedule. Usually we provide a faster delivery than the industry's average.

Q:What is the payment term?

A:Our payment terms are negotiable.

Q:Can I have my own logo on the product?

A:Sure, we can apply your own logo on the products according to your drawings.

- Q: What are the hazards of solid clay bricks?

- According to incomplete statistics, China produces about 70000000 tons of standard coal per year of clay bricks.

- Q: General used refractory brick T-20 / T-39/ T-206 specifications and dimension

- No T-206 model (we produce the clay) T-20 and T-39 are the size of 230*length, 113* width and 65/45 thickness, T-20 is a vertical arch brick and T-39 is horizontal arch brick.

- Q: What is the use of refractory bricks

- Antifreeze

- Q: The renewal of refractory brick internal the lime kiln belongs to overhaul. In the absence of production, are the replacement of valve and sporadic projects also considered overhauls? Or routine maintenance!

- The replacement of refractory brick for lime kiln is definitely a major overhaul, and the replacement of the valve and sporadic items can only be regarded as routine maintenance.

- Q: Is the waste of the fire resistant hazardous waste?

- Can be recycled and reused.

- Q: What is the difference between clay brick, glazed tile and brick?

- Glazed tiles are bricks that have been burnt and glazed on the surface of bricks. Is the surface of glaze firing together, the main body consists of clay and clay two, back out of the red clay, abaxially grayish white porcelain clay fire. Glazed tile surface can do a variety of patterns and patterns, than polished brick color and pattern rich, because the surface is glaze, so wear resistance is better than polished brick.

- Q: Red brick (solid clay brick) has been banned, why do few people know?

- The red brick of hollow brick to heavy masonry, the same thickness of the wall brick, hollow brick firing than required amount of clay to about 1/3, and the consumption of coal fired brick is fired hollow bricks to smoke, emissions are also big, serious damage to the environment.

- Q: Are refractory bricks necessarily needed to build a kitchen stove?

- It will be better to use refractory bricks for long term because of its high temperature resistance

- Q: What are the advantages and disadvantages of clay bricks?

- Disadvantages of clay bricks1., since the majorCompared with other masonry materials, the weight of the clay brick is relatively large, so the structure needs to bear heavy deadweight, and the cost of the building increases. 2., poor sound insulation effectSound travels to the clay brick, because of its low porosity, without isolation of sound, sound decibel little drop, while other building materials such as now used more concrete block filling the void ratio is large, sound insulation effect is obvious.3, environmental destructionBecause clay bricks are mainly sintered by excavation soil, soil erosion and damage to vegetation have resulted in soil erosion and serious damage to the environment. Therefore, the country is gradually stopping the project to use clay bricks.

- Q: application of phosphate refractory bricks

- The 4 properties of phosphate refractory bricks: (1) high strength wear resistance (2) and chemical erosion (its alkali resistant ability is better than that of clay brick and high alumina brick) (3) and good thermal shock resistance (4) high load softening temperature in rotary kiln, kilneye, kiln Zone door cover, cooling machine and lining refractory brick falling parts easy to loose

Send your message to us

Fireclay Brick - Good Price and High Quality MgO-C Brick for Steel Ladle

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords