Fireclay Brick (Al2O3 58-60) for Glass Furnace

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

What is the feature of Fireclay Brick?

l Fireclay Bricks or fire bricks are the most widely used refractory bricks because of its great features: low thermal conductivity, good thermal insulation performance; High resistance to Thermal shock, abrasion, chemical attack to provide long service life; easy operation and installation; broad usage or applications and low price etc.

l High density with low porosity fire clay bricks is our featured product in this category. Due to its low apparent porosity rate, high density with low porosity bricks have great features of strong resistance to erosion, high refractoriness under load, great Cold Crushing strength and high mechanical strength etc.

Application of Fireclay Bricks

CMAX fireclay bricks are commonly applied in blast furnace, hot blast furnace, teeming ladle, glass furnace, etc.

Image of Fireclay Brick

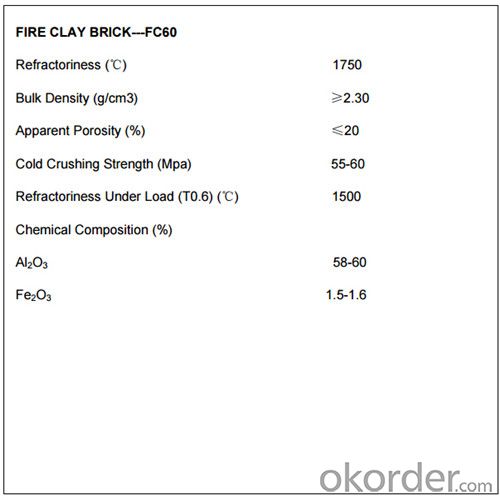

Technical Data of Fireclay Brick

Why Choose Us

l We are a government owned company with ISO certificate.

l We are listed in Global Fortune 500 with D & B report.

l We have more than 11 refractory production facilities and bases across China. We have a wide products range, such as ceramic fiber products (ceramic fiber blanket, module, board, paper, bulk), ceramic fiber textile (ceramic fiber rope, cloth, tape, yarn) etc, refractory brick (fireclay brick, high alumina brick, silica brick, magnesia brick etc), monolithic refractory materials, insulating fire brick, calcium silicate board, mica sheet, steel fiber. You can find various products here, and we can combine the light weight ceramic fiber products with the heavy weight refractory brick in one container delivery, then save the sea freight for you.

l We have strict materials selecting system and quality control system. We have the ability to take responsibility for your orders and product quality.

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control is conducted by workers and then each piece will be sorted and examined by quality supervisor.

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days

for refractory bricks, 10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such as U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q: Why is the house made of refractory bricks not warm in winter

- Heating equipment can be used

- Q: There are various refractory materials inside many kilns such as refractory brick, what is the role of masonry of these refractory materials?

- When the steel is made, and wear) to complete the purpose of steelmaking, the liquid inside the kiln is melted liquid steel (1550 DEG C), erosion, only the masonry of refractory brick (melt above 1550 DEG C and has a certain strength) can resist various effects of molten steel (melting

- Q: What are the simple ways to distinguish between excessive clay bricks and less fired clay bricks?

- When the production of sintered clay brick, brick baking in an oxidizing environment and a kiln, produce red brick; if the first brick in an oxidizing roasting, and then watering stuffy kiln, the kiln to form reducing atmosphere, makes the three brick red iron oxide is reduced to a high oxygen low iron and preparation so blue. The durability of brick brick than good.

- Q: Is the waste of the fire resistant hazardous waste?

- Refractory waste should refer to the used refractory material, which more or less have some pollution. low grade material such as clay brick and high alumina brick can be used repeatedly on the spot, such as breaking it and making it into waste refractory bricks sand, unshaped refractory meterial or low-grade refractory brick, or just bury it in a pit. collect high grade bricks such as corundum brickand silicon carbide brick and sell, they are sought after, the price per ton ranges from several hundred to several thousand. pay special attention not to dispose waste refractory bricks containing metal chromium at random, for it is toxic and carcinogenic. Collect them and seal them up, looking for manufacturers to buy and reuse.

- Q: th choose of different refractory bricks in the rotary?kiln

- According to the characteristics of each belt, magnesium chromium brick. Take the most kiln foe example, the configuration of kiln refractory is not the same, the burning of the product is not the same. there are many kinds of rotary kiln. magnesia bricks are generally used in high temperature zone, anti-stripping alumina brick,silmo brick are used in temperate zone, clay brick is mainly used in low temperature zone. generally inlet and the outlet use corundum mullite, wear-resistant castable, spinel brick,etc. select brick of proper performance, but also take into account the economy

- Q: Tunnel kiln firing refractory brick by 0 against the good rely on

- Modern advanced kiln has high temperature strength and good thermal shock resistance, better environmental protection, is the most economical and efficient kiln. (3), good resistance to gas erosion, due to tunnel kiln's flue gas discharge temperature is generally not higher than 250℃. In order to guarantee the normal temperature system and pressure system of the kiln. Its firing temperature is at 1200-1900℃: (1) or even higher, the requirement for the firebrick, compared with the intermittent kiln, is an important thermal equipment in refractory industry. It is a kind of energy-saving kiln. Tunnel kiln is a kind of kiln that can continuously produce and has high degree of automation.

- Q: The boiler is divided into several categories according to the structure, what characteristics does each have?

- package boiler and assemble boiler are divided into vertical boiler and horizontal boiler. Vertical boiler. Assembled boiler adapts to boiler more than 6 tons, the package adapts to boiler less than 10 tons.

- Q: With what three clay brick clay brick with six holes under what circumstances?

- Local material. The two kinds of pumping rate are different, the thermal resistance is different, the volume density and thermal conductivity have some differences, but also by the designer's habits, and local production, the impact of the market.

- Q: What can be applied to the burned refractory brick to resist heat shock?

- Acidic refractory material use monox as the main component, among which cilica brick and clay brick are commonly used. Silica brick is silicious product containing monox more than 93%, whose raw materials include silica, waste silica brick scrap and etc. The acid resistance of slag erosion ability is good, and the softening temperature under a fixed load is high. The volume won't shrink after repeated burning, but even a slight expand; but it is vulnerable to the erosion of basic slag, and has low thermal shock resistance. The silica brick is mainly used for coke oven, glass melting furnace, acid hearth furnace and other thermal equipments. Clay brick uses refractory clay as the main raw material, containing 30% to 46% of aluminuum oxide, belong to weakly acidic refractories. It has good heat shock resistance and corrosion stability to acid slag, and it's widely used. Neutral refractory materials use aluminum oxides, chromium hemitrioxides or carbons as the main components. Corundum products containing more than 95% of alumina is a kind of high quality refractory material with wide application.

- Q: What are the physical and chemical properties of refractory bricks

- The thermal shock stability, linear?change?on?reheating, softening temperature under a fixed load, compressive strength under normal strength refractoriness

Send your message to us

Fireclay Brick (Al2O3 58-60) for Glass Furnace

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords