Fire Resistant PU Coated Fiberglass Fabrics

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description: PU coated fabric is fiberglass cloth coated with flame retarded PU (polyurethane) on one-sided or double-sided surface. PU coating imparts fiberglass cloth good weave setting (high stability) and water resistance properties. PU coated fiberglass cloth can withstand a continuous working temperature of 550℃ and a short duration working temperature of 600℃. Compared with basic woven glass fiber fabric, It has many good features such as good air gas sealing, fire resistant, abrasion resistance, oils, solvents resistance chemical resistant ability, no skin irritation, halogen free. Can be used in fire and smoke applications, such as welding blanket, fire blanket, fire curtain, fabric air distribution ducts, fabric duct connector. We can offer polyurethane coated fabric with different colors, thickness, widths.

Features: Fire Resistant, Water Resistant, Abrasion Resistance

Application: Fabric Expansion Joint, Flexible Connector, Fireproof Curtain, Welding Curtain, Smoke Curtain, Welding Blanket, Fire Blanket, Insulation Cover

PRICE: USD3 per square meter

UNIT: square meter

MOQ: 500square meters

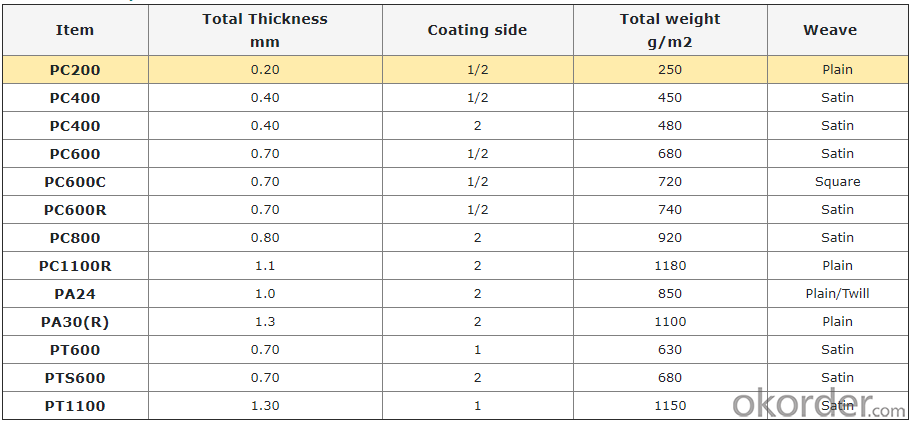

Weight: 210gsm-1800gsm

Width: 1m-2m or customized

Yarn Type: E-glass

Standing temperature -50℃-550℃

Product name: PU coated fiberglass fabric

Coating/Finish/Surface Treatment: PU coated

Roll length: 50 meter or customized

Color: Grey, Red, White, Green, Blue, Yellow, or customized

Weave Type: twill woven

Alkali content: alkali free

Processing service: cutting

Material: fiberglass PU

Thickness: 0.2mm to 3mm

Size: can be customized

Supply ability: 300000 meters per month

Packaging: PU coated fiberglass fabric rolls packed in cartons loaded on pallets or according to customers’ requirements

Lead time: 7-30 days

- Q: Can fiberglass fabric be used for insulation in aerospace applications?

- Certainly, fiberglass fabric has the capability to be utilized for insulation purposes in aerospace settings. Renowned for its exceptional thermal insulation characteristics, fiberglass fabric proves to be an optimal selection for aerospace applications where temperature control is of utmost importance. It possesses traits such as being lightweight and flexible, along with the ability to endure high temperatures, rendering it suitable for deployment in various aerospace components like engine compartments, fuel tanks, and aircraft interiors. Moreover, fiberglass fabric exhibits resistance towards chemicals, moisture, and fire, thereby providing an additional layer of safety and safeguarding in aerospace environments. In conclusion, due to its remarkable thermal properties and durability, fiberglass fabric is a dependable and extensively employed insulation material in aerospace applications.

- Q: Can fiberglass fabrics be used in high-temperature environments?

- Yes, fiberglass fabrics can be used in high-temperature environments. They have excellent heat resistance properties and can withstand temperatures up to 1000°F (538°C) without losing their structural integrity. This makes them suitable for applications such as insulation, fireproofing, and thermal protection in industries like aerospace, automotive, and manufacturing.

- Q: Can fiberglass fabrics be used for insulation in appliances?

- Indeed, fiberglass fabrics possess the capability to serve as insulation within appliances. These fabrics consist of interwoven glass fibers, which exhibit exceptional resistance to high temperatures and superb insulation qualities. They effectively capture and maintain heat, rendering them perfect for insulating appliances like ovens, stoves, and refrigerators. Moreover, fiberglass fabrics are lightweight, pliable, and simple to handle, enabling effortless installation in diverse appliance designs. Additionally, they boast durability and the ability to endure elevated temperatures without deteriorating or compromising their insulation properties. All in all, fiberglass fabrics represent a dependable and effective option for appliance insulation.

- Q: Are fiberglass fabrics suitable for use in aerospace applications?

- Yes, fiberglass fabrics are suitable for use in aerospace applications. Fiberglass is a lightweight and high-strength material, which makes it ideal for aerospace applications where weight reduction is crucial. It has excellent mechanical properties, including high tensile strength, stiffness, and resistance to temperature variations, which are important for withstanding the extreme conditions experienced in aerospace environments. Fiberglass fabrics also have good electrical insulation properties, making them suitable for applications where protection against electromagnetic interference is necessary. Additionally, fiberglass fabrics can be engineered to be fire-resistant, further enhancing their suitability for aerospace applications. Overall, the combination of lightweight, high strength, temperature resistance, electrical insulation, and fire resistance makes fiberglass fabrics a reliable and suitable choice for use in aerospace applications.

- Q: What is the material of the computer mainboard PCB?

- The flat surface of the motherboard is a PCB printed circuit board which is divided into four layers and six boards. Four layers: main signal layer, ground layer, power layer and sub signal layer.

- Q: How does fiberglass fabric perform in thermal expansion?

- Fiberglass fabric exhibits satisfactory performance in terms of thermal expansion. Its composition of interwoven glass fibers results in a minimal coefficient of thermal expansion (CTE), causing it to expand and contract at a negligible rate when exposed to temperature changes. This attribute renders it highly suitable for applications that require dimensional stability, including composite materials, insulation, and thermal protection systems. The low CTE of fiberglass fabric effectively prevents warping, distortion, and cracking that may occur in materials with higher rates of thermal expansion. Furthermore, the fabric's capacity to endure high temperatures without significant expansion further enhances its efficacy in thermal expansion applications. All in all, the fabric's low CTE contributes to its versatility and dependability in diverse industries, establishing it as the preferred choice for applications sensitive to thermal expansion.

- Q: How does fiberglass fabric perform in weight-to-strength ratio?

- Fiberglass fabric performs exceptionally well in terms of weight-to-strength ratio. It is known for its high strength despite being lightweight, making it an ideal material for various applications where strength is crucial, such as aerospace, automotive, and construction industries.

- Q: How does fiberglass fabric perform in chemical resistance?

- Fiberglass fabric possesses excellent chemical resistance properties in general. Its ability to withstand a wide range of chemicals, including acids, alkalis, solvents, and most organic compounds, is well-known. This can be attributed to the fact that fiberglass is composed of non-reactive glass fibers, which do not easily degrade or dissolve when exposed to different chemicals. To further enhance the chemical resistance of fiberglass fabric, specific coatings or treatments can be applied. For example, a silicone coating can provide additional protection against certain chemicals and improve overall resistance. Some manufacturers even offer specialty fiberglass fabrics that are specifically designed to resist particular chemicals or environments, such as high-temperature or corrosive conditions. However, it is important to acknowledge that the chemical resistance of fiberglass fabric may vary depending on the specific chemical and the duration and intensity of exposure. Prolonged exposure to aggressive chemicals or certain substances may eventually lead to fabric degradation or damage. Therefore, it is advisable to consult the manufacturer's guidelines or conduct specific chemical compatibility tests to ensure optimal performance in a given chemical environment.

- Q: How are fiberglass fabrics manufactured?

- Fiberglass fabrics are manufactured by weaving or knitting strands of glass fibers together to create a flexible and strong textile material. The process involves melting glass into fine filaments, which are then formed into yarns. These yarns are then woven or knitted into various patterns, depending on the desired strength and texture of the fabric. The resulting fiberglass fabrics can be used in a wide range of applications, including insulation, reinforcement, and composite materials.

- Q: What is the average thickness of fiberglass fabric?

- The average thickness of fiberglass fabric can vary depending on the specific application and manufacturing process. However, in general, fiberglass fabric typically ranges from 0.2 millimeters (0.008 inches) to 0.5 millimeters (0.02 inches) in thickness.

Send your message to us

Fire Resistant PU Coated Fiberglass Fabrics

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords