Fiberglass Mat Tissue Sandwich Fabric Complex Mat 1380g 200~2600 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description & application | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

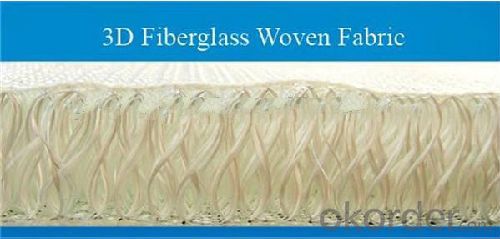

◎ 3D Fabric can be made of glass fiber, carbon fiber or basalt fiber. Hybrid fabrics also can be produced. The thickness of 3D Fiberglass Fabric ranges from 3.4 mm to 22.6 mm and the width of it measures no more than 3000 mm. Processed with resin, 3D Fiberglass Fabric gains an outstanding capability of anti-debonding, impact resistant, lightweight and high strength, thermal insulating and acoustic damping. 3D Fiberglass Fabric is often the first choice for many enterprises to manufacture framework members of automobile, locomotives, aerospace, ship, sports, wind generator, construction, decoration, ect.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Main Traits | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

◎ The structure of sandwich to increase strength, reduce product weight and better surface finish. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Each roll is wrapped by PE film and then packed into carton. Stacking in bulk or palletized is available; the pallet shall be no higher than 2 layers.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

FAQ

Q : Are you a factory or trading company ?

A: We have factories , can offer best quality product and reasonable price for you.

Q: Can you accept sample order?

A: Yes, we accept samples with little and reasonable charge

Q: What is your MOQ?

A: Normally,4 rolls.

- Q: Can fiberglass mat tissue be used for pipe insulation?

- Typically, pipe insulation does not involve the use of fiberglass mat tissue. Fiberglass mat tissue is a thin substance commonly utilized for reinforcement in different industries, rather than for thermal insulation or preventing heat loss in pipes. When it comes to insulating pipes, materials like foam, mineral wool, or fiberglass pipe insulation are more commonly employed. These materials are specifically designed to offer thermal insulation and safeguard pipes against heat loss, condensation, and freezing.

- Q: What is the moisture resistance rating of fiberglass mat tissue?

- The moisture resistance rating of fiberglass mat tissue may differ depending on the specific product and manufacturer. Nonetheless, fiberglass mat tissue is renowned for its exceptional moisture resistance properties. It is typically engineered to exhibit high resistance against water absorption, rendering it suitable for applications where moisture exposure is a concern. This moisture resistance attribute aids in preserving the structural integrity and performance of the fiberglass mat tissue, even under humid or wet conditions. It is crucial to consider the manufacturer's provided product specifications to ascertain the precise moisture resistance rating when selecting fiberglass mat tissue for a particular application.

- Q: Is fiberglass mat tissue suitable for aerospace interiors?

- Yes, fiberglass mat tissue is suitable for aerospace interiors. It is a lightweight and durable material that offers excellent fire resistance and insulation properties, making it a suitable choice for various applications in aerospace interiors, such as insulation, soundproofing, and reinforcing materials. Additionally, fiberglass mat tissue can be easily molded and shaped to fit specific design requirements, making it a versatile option for aerospace interior components.

- Q: Is fiberglass mat tissue resistant to UV degradation?

- Fiberglass mat tissue is generally resistant to UV degradation to some extent. However, its level of resistance may vary depending on the specific type and quality of the fiberglass mat tissue. UV degradation occurs when prolonged exposure to ultraviolet (UV) radiation from the sun causes the degradation of materials. This degradation can lead to discoloration, brittleness, and reduced strength in the material. Fiberglass mat tissue is often manufactured with additives and coatings that provide some level of UV resistance. These additives and coatings help to protect the fibers from the damaging effects of UV radiation. However, it is important to note that the level of UV resistance can vary between different manufacturers and products. To ensure maximum UV resistance, it is recommended to choose fiberglass mat tissue that is specifically designed for outdoor applications and has been tested for UV stability. Additionally, proper maintenance and periodic inspections can help to identify any signs of UV degradation and allow for timely repairs or replacements if necessary.

- Q: Can fiberglass mat tissue be used in structural applications?

- Indeed, structural applications can make use of fiberglass mat tissue. This lightweight and flexible material is frequently employed as reinforcement in construction and engineering endeavors. It is often combined with resin or concrete to enhance the structural integrity of diverse components. The remarkable strength-to-weight ratio of fiberglass mat tissue renders it exceptionally fitting for reinforcing walls, roofs, and floors. Furthermore, its resistance to corrosion, moisture, and chemicals allows for its utilization in diverse environments. The wide-ranging applicability and enduring nature of fiberglass mat tissue contribute to its widespread preference in structural applications.

- Q: Can fiberglass mat tissue be used for insulating crawl spaces?

- Yes, fiberglass mat tissue can be used for insulating crawl spaces. It is a commonly used material for thermal insulation due to its good insulation properties and moisture resistance. It can help to reduce heat loss and prevent moisture buildup in crawl spaces, making it an effective choice for insulating this area.

- Q: What is the composition of fiberglass mat tissue?

- Fiberglass mat tissue, also known as fiberglass mat or fiberglass veil, is made up of a combination of fiberglass fibers and a binder material. The fiberglass fibers used in the composition are typically made from silica, a naturally occurring mineral. These fibers are known for their high strength and durability. The binder material used in fiberglass mat tissue can vary, but commonly includes substances like urea-formaldehyde, acrylic, or polyester resins. The role of the binder is to hold the fiberglass fibers together and provide structural integrity to the mat. In addition to the fiberglass fibers and binder, other additives may be included in the composition of fiberglass mat tissue. These additives can include substances such as pigments, fire retardants, or coatings, depending on the specific application and desired properties of the mat. Overall, the composition of fiberglass mat tissue is a combination of fiberglass fibers and a binder material, with additional additives depending on the intended use. This composition allows fiberglass mat tissue to possess excellent strength, flexibility, and resistance to various environmental factors, making it a versatile material used in various industries such as construction, automotive, aerospace, and marine.

- Q: Is fiberglass mat tissue resistant to chemicals?

- Yes, fiberglass mat tissue is generally resistant to chemicals. It is commonly used in applications where chemical resistance is required, such as in the construction of chemical storage tanks or pipes. However, the specific resistance of fiberglass mat tissue to different chemicals may vary, so it is important to consult the manufacturer's specifications for the intended chemical environment.

- Q: Can fiberglass mat tissue be used for automotive applications?

- Yes, fiberglass mat tissue can be used for automotive applications. It is commonly used in the automotive industry for reinforcement and strength in parts such as body panels, hoods, and interior components. It provides excellent thermal and acoustic insulation properties as well.

- Q: What are the different color options available for fiberglass mat tissue?

- Various color options are offered for fiberglass mat tissue, catering to different preferences and applications. White, gray, black, and beige are among the commonly available colors. These color choices offer versatility in design and aesthetics, allowing users to select a color that enhances their individual project needs. Factors like UV resistance and desired visibility or camouflage levels can also influence the color selection. In conclusion, the availability of diverse color options for fiberglass mat tissue grants users the flexibility and customization opportunities necessary to achieve their desired results.

Send your message to us

Fiberglass Mat Tissue Sandwich Fabric Complex Mat 1380g 200~2600 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords