Fiberglass Mat Tissue E-Glass Fiberglass Woven Roving 800g 1200mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

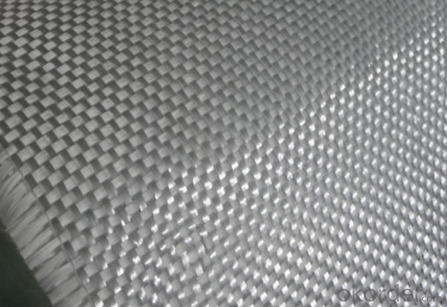

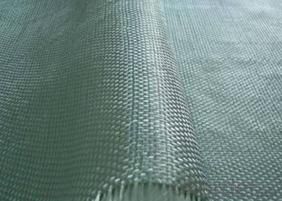

Structure of woven roving Description

Woven roving is made of direct rovings in Plain,Twill weave pattern.The input rovings are designed to give controlled wet-out and excellent laminate properties. It is compatible with Polyester,Vinyl ester and Epoxy resin and widely used in hand machine production, such as boats,vessels,plane and automotive parts,furniture,sports and other areas.

Main Features of the woven roving

Consistet thickness and excellent surface treatment;

Rapid impregnating and good compatibility with resin;

Uniform tension, high dimensional stability and easy operation;

Good mechanical properties and high strength of parts

Woven roving Images

Woven roving Specification:

Normal type | EWR800 | EWR400 | EWR300 | EWR500 | EWR600 |

Thickness (mm) | 0.8 | 0.4 | 0.3 | 0.5 | 0.6 |

Density(warpxweft) (end/cm) | 1.8x1.5+/-10% | 3.6x3.2+/-10% | 4.6x4.1+/-10% | 2.2X2.0+/-10% | 2.6X2.4+/-10% |

Tex (warpxweft) | 2400x2400 | 600X600 | 300x400 | 1200x1200 | 1200X1200 |

Moisture content(%) | <0.2% | <0.2% | <0.2% | <0.2% | <0.2% |

Loss on ignition(%) | 0.4 – 0.8 | 0.4-0.8 | 0.4-0.8 | 0.4-08 | 0.4-0.8 |

Width(cm) | 125+/-1 | 125+/-1 | 125+/-1 | 125+/-1 | 125+/-1 |

Weight (g/m2) | 816+/-41 | 408+/-32 | 300+/-15 | 500+/-25 | 600+/-30 |

Weight per roll(kg) | 45 | 46 | 50 | 45 | 45 |

Glass | E-glass | E-glass | E-glass | E-glass | E-glass |

FAQ of woven roving:

1.Q: What specification do you have for e-glass woven roving ?

A: Now our normal specification have 400/450/500/600/800g/m2, But 200 - 1600g/m2 are available.

2.Q:How about the width?

A:The normal width is 1040mm and 1270mm, can be from 50mm to 3000mm.

3.Q:How about the sample delivery?

A.Small sample is free of charge, sample ready time 3-5days.

4.Q:How about the delivery time?

A:It is depend on the order quantity, three 20'ft container around 20days.

Application of Fiberglass Woven Roving:

a) boats ,vessels ,plane

b) automotive parts ,furniture and sports facilities

c) resins system,such as polyeser,vinylester and epoxy resins

- Q: Is fiberglass mat tissue chemically resistant?

- Yes, fiberglass mat tissue is chemically resistant. Fiberglass mat tissue is made from fine glass fibers that are randomly oriented and bound together with a resin binder. This composition allows the material to exhibit excellent resistance to a wide range of chemicals including acids, alkalis, solvents, and oils. It is commonly used in industries such as chemical processing, petrochemicals, and wastewater treatment where exposure to various chemicals is common. The chemical resistance of fiberglass mat tissue makes it a suitable choice for applications requiring corrosion resistance and long-term durability.

- Q: Can fiberglass mat tissue be used for lightweight construction?

- Yes, fiberglass mat tissue can be used for lightweight construction. Fiberglass mat tissue is a thin and lightweight material made up of randomly oriented glass fibers bonded together with a binder. It is commonly used as a reinforcement material in composite laminates and is known for its excellent strength-to-weight ratio. In lightweight construction, where weight reduction is a key consideration, fiberglass mat tissue can be an ideal choice. Its low weight adds minimal additional load to the structure while still providing sufficient strength and durability. The random orientation of the fibers in the mat tissue ensures that the load is evenly distributed, further enhancing its strength properties. Additionally, fiberglass mat tissue is easy to handle and can be easily molded into various shapes and forms. This flexibility makes it suitable for applications in lightweight construction, such as in the production of lightweight panels, wall partitions, and roof structures. The material can also be used in combination with other lightweight materials, such as foam cores or honeycomb structures, to further enhance its lightweight properties. Overall, fiberglass mat tissue is a versatile material that can be effectively used for lightweight construction. Its lightweight nature, combined with its strength and durability, make it a suitable choice for various applications where weight reduction is a priority.

- Q: How does fiberglass mat tissue perform in terms of chemical resistance?

- Fiberglass mat tissue generally exhibits good chemical resistance due to the inherent properties of fiberglass, making it suitable for various applications where exposure to chemicals is a concern.

- Q: Is fiberglass mat tissue biodegradable?

- No, fiberglass mat tissue is not biodegradable. Fiberglass is a synthetic material made from fine fibers of glass, which are woven together to create a strong and durable material. These fibers do not break down naturally over time, making fiberglass mat tissue non-biodegradable.

- Q: Can fiberglass mat tissue be used for insulation in pharmaceutical storage areas?

- No, fiberglass mat tissue is not suitable for insulation in pharmaceutical storage areas. This material may release particles or fibers that can contaminate the pharmaceutical products, which could compromise their quality and safety. It's essential to use insulation materials that are specifically designed and approved for pharmaceutical storage areas to ensure optimal conditions and adherence to regulatory standards.

- Q: What are the different types of resins compatible with fiberglass mat tissue?

- There are several different types of resins that are compatible with fiberglass mat tissue. These resins include polyester resin, epoxy resin, vinyl ester resin, and polyurethane resin. Polyester resin is one of the most commonly used resins in fiberglass mat applications. It is cost-effective and has good mechanical properties, making it suitable for a wide range of applications. Polyester resin is also easy to work with and provides good resistance to water and chemicals. Epoxy resin is another popular choice for fiberglass mat tissue. It offers excellent mechanical properties, high strength, and good resistance to chemicals and moisture. Epoxy resin is often used in applications that require superior strength and durability, such as aerospace and marine industries. Vinyl ester resin is a hybrid between polyester and epoxy resins. It combines the best properties of both resins, offering high strength, good corrosion resistance, and excellent durability. Vinyl ester resin is commonly used in applications where high chemical resistance and superior mechanical properties are required. Polyurethane resin is a versatile resin that can be used with fiberglass mat tissue. It offers excellent flexibility, impact resistance, and adhesion properties. Polyurethane resin is often used in applications that require high flexibility and resistance to abrasion, such as automotive parts and sporting goods. Overall, the choice of resin depends on the specific requirements of the application, including mechanical properties, chemical resistance, flexibility, and cost.

- Q: What is the flexibility of fiberglass mat tissue?

- The flexibility of fiberglass mat tissue refers to its ability to bend, conform, or mold to different shapes or surfaces without breaking or losing its structural integrity. The unique properties of fiberglass, such as its high strength-to-weight ratio and dimensional stability, allow the mat tissue to be flexible while still maintaining its strength and durability. This flexibility makes fiberglass mat tissue a versatile material that can be used in a wide range of applications, including automotive parts, construction materials, and boat manufacturing. Additionally, the flexibility of fiberglass mat tissue enables it to be easily cut, shaped, or layered to meet specific design requirements or fit into complex or curved surfaces.

- Q: How does the surface finish of fiberglass mat tissue affect its adhesion to resin?

- The adhesion of resin to fiberglass mat tissue can be significantly influenced by its surface finish. The surface finish pertains to the texture or smoothness of the fiberglass mat tissue. In general, a rough surface finish tends to promote better adhesion to resin. This is because a rough surface provides a larger area for the resin to adhere to, resulting in a stronger bond. Rough surface finishes can be achieved through different manufacturing techniques, such as using coarser fibers or incorporating texturizing agents during production. On the contrary, a smoother surface finish may lead to weaker adhesion. A smooth surface does not offer as much area for the resin to bond with, resulting in a weaker and less durable bond. Smoother surface finishes can be attained by using finer fibers or through additional processing steps to smoothen the surface. When selecting the surface finish of fiberglass mat tissue, it is crucial to consider the specific application and requirements. For applications that necessitate high strength and durability, a rougher surface finish may be preferable to ensure optimal adhesion to the resin. Conversely, for applications where a weaker bond is acceptable or where a smoother surface finish is desired for aesthetic reasons, a smoother surface finish may be chosen. Ultimately, the surface finish of fiberglass mat tissue plays a vital role in determining the adhesion to resin. It is essential to choose the appropriate surface finish to achieve the desired strength, durability, and performance in various applications.

- Q: How does fiberglass mat tissue perform in terms of dimensional stability?

- Fiberglass mat tissue performs exceptionally well in terms of dimensional stability. Its unique composition of fine fibers and binders helps it maintain its shape and structure even under significant stress or changes in temperature and humidity. This makes it ideal for applications where dimensional stability is crucial, such as in the construction of composite materials, automotive parts, and insulation products.

- Q: Does fiberglass mat tissue provide any acoustic insulation?

- Yes, fiberglass mat tissue provides acoustic insulation as it effectively absorbs and dampens sound waves, reducing noise transmission and improving soundproofing properties.

Send your message to us

Fiberglass Mat Tissue E-Glass Fiberglass Woven Roving 800g 1200mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords