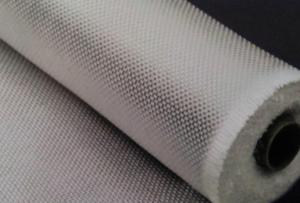

Fiberglass Mat Tissue E-Glass Fiberglass Woven Roving, 400g, 1040mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

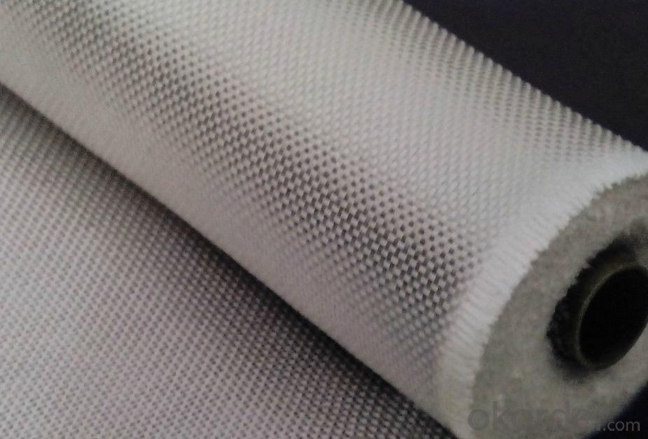

Structure of woven roving Description

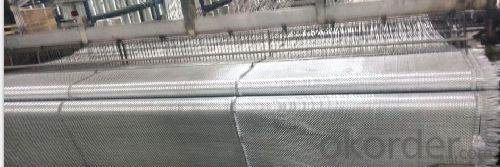

Glass woven rovings are bidirectional fabric by direct rovings in plain weave pattern. They are applicable for hand lay-up, winding and compress molding process, suitable for manufacturing tank, boat, automobile parts and other FRP products.

1,high strenth,corosion and resistence

2,consistent thickness,no fuzz

3,rapid impregnating

Main Features of the woven roving

1)Drapes well to suit the surface of intricate moulds

2)Fast wet-through and wet out

3)Easy handing and better appearance of the composite parts

4)Compatible with Unsaturated polyester resin

5)Very high laminate strength properties

Woven roving Images

Woven roving Specification:

Normal type | EWR800 | EWR400 | EWR300 | EWR500 | EWR600 |

Thickness (mm) | 0.8 | 0.4 | 0.3 | 0.5 | 0.6 |

Density(warpxweft) (end/cm) | 1.8x1.5+/-10% | 3.6x3.2+/-10% | 4.6x4.1+/-10% | 2.2X2.0+/-10% | 2.6X2.4+/-10% |

Tex (warpxweft) | 2400x2400 | 600X600 | 300x400 | 1200x1200 | 1200X1200 |

Moisture content(%) | <0.2% | <0.2% | <0.2% | <0.2% | <0.2% |

Loss on ignition(%) | 0.4 – 0.8 | 0.4-0.8 | 0.4-0.8 | 0.4-08 | 0.4-0.8 |

Width(cm) | 125+/-1 | 125+/-1 | 125+/-1 | 125+/-1 | 125+/-1 |

Weight (g/m2) | 816+/-41 | 408+/-32 | 300+/-15 | 500+/-25 | 600+/-30 |

Weight per roll(kg) | 45 | 46 | 50 | 45 | 45 |

Glass | E-glass | E-glass | E-glass | E-glass | E-glass |

FAQ of woven roving:

Delivery Detail: 15-21days

Other spec. can be custom made as per customer's request.

Application of Fiberglass Woven Roving:

a) boats ,vessels ,plane

b) automotive parts ,furniture and sports facilities

c) resins system,such as polyeser,vinylester and epoxy resins

- Q: What is the dimensional stability of fiberglass mat tissue?

- The dimensional stability of fiberglass mat tissue refers to its ability to maintain its shape and size even when exposed to changes in temperature, humidity, or mechanical stress. Due to its high strength and stiffness, fiberglass mat tissue is known for its excellent dimensional stability, making it suitable for various applications such as insulation, reinforcement, and composite materials.

- Q: Is fiberglass mat tissue suitable for automotive body panel repairs?

- Yes, fiberglass mat tissue is suitable for automotive body panel repairs. Fiberglass mat tissue is a versatile material that is commonly used in automotive repairs due to its strength, durability, and flexibility. It is particularly effective in repairing body panels as it can be molded and shaped to fit the unique contours of the vehicle. Additionally, fiberglass mat tissue is resistant to corrosion, moisture, and chemicals, making it an ideal choice for automotive applications. Its lightweight nature also helps to minimize the overall weight of the vehicle, improving fuel efficiency. Overall, fiberglass mat tissue is a reliable and effective material for automotive body panel repairs.

- Q: Can fiberglass mat tissue be used for insulation in cryogenic applications?

- Indeed, insulation in cryogenic applications can be accomplished using fiberglass mat tissue. Renowned for its exceptional thermal insulation properties, fiberglass is a versatile substance. Its capability to diminish heat transfer is heightened due to its low thermal conductivity. Consequently, it is remarkably suitable for cryogenic applications that necessitate the maintenance of exceedingly low temperatures. Furthermore, fiberglass possesses non-combustible qualities and does not absorb moisture, rendering it the perfect choice for cryogenic environments. By implementing it as an insulation layer, fiberglass can effectively impede heat transfer and sustain the desired low temperatures in cryogenic storage tanks, pipes, and other related equipment.

- Q: Can fiberglass mat tissue be used for making lightweight ceilings?

- Yes, fiberglass mat tissue can be used for making lightweight ceilings. It is a strong and lightweight material that is commonly used in construction for its fire resistance, durability, and insulation properties. It can be easily molded and shaped to create lightweight ceiling panels, making it an ideal choice for applications where weight reduction is desired.

- Q: Is fiberglass mat tissue suitable for insulation in sports facilities?

- Sports facilities can benefit from the use of fiberglass mat tissue for insulation. Fiberglass is a widely utilized material for insulation because of its outstanding thermal properties and fire resistance. It effectively insulates, maintaining a comfortable indoor environment by preventing heat loss or gain. Moreover, fiberglass insulation is lightweight, sturdy, and simple to install, which makes it perfect for sports facilities that require insulation across large areas. It is also resistant to moisture and does not encourage the growth of mold or mildew, guaranteeing a healthy and sanitary atmosphere. All things considered, fiberglass mat tissue is a dependable and effective choice for insulating sports facilities.

- Q: Can fiberglass mat tissue be used for insulation in cold climates?

- Yes, fiberglass mat tissue can be used for insulation in cold climates. It is a commonly used material for insulation due to its low thermal conductivity and ability to trap air, providing effective insulation against cold temperatures.

- Q: Can fiberglass mat tissue be used for flooring applications?

- No, fiberglass mat tissue is not typically used for flooring applications. It is commonly used in industries such as automotive, construction, and marine for insulation, reinforcement, and insulation purposes. Flooring applications usually require different materials such as tiles, hardwood, laminate, or vinyl.

- Q: Does fiberglass mat tissue require any special surface treatments before application?

- Yes, fiberglass mat tissue does require special surface treatments before application. These treatments are necessary to ensure proper adhesion and bonding between the fiberglass mat tissue and the substrate it is being applied to. One common surface treatment is the application of a primer or bonding agent. This helps to improve the bond strength between the fiberglass mat tissue and the substrate. The primer or bonding agent is typically applied to the substrate and allowed to dry before the fiberglass mat tissue is applied. Another surface treatment is the removal of any loose or flaking material from the surface of the substrate. This can be done through mechanical methods such as sanding or grinding, or by using a chemical treatment to dissolve or remove the unwanted material. This step is important to create a clean and smooth surface for the fiberglass mat tissue to adhere to. In some cases, the surface of the substrate may need to be roughened or etched to provide a better bonding surface for the fiberglass mat tissue. This can be done using abrasives or chemical etching agents, depending on the type of substrate being used. Overall, the specific surface treatment required for fiberglass mat tissue will depend on factors such as the type of substrate, the desired bond strength, and the application method being used. It is important to follow the manufacturer's instructions and recommendations for surface preparation to ensure a successful application and long-lasting bond.

- Q: Does fiberglass mat tissue provide good thermal conductivity?

- No, fiberglass mat tissue does not provide good thermal conductivity. Fiberglass is known for its insulating properties, meaning it is a poor conductor of heat. It has a low thermal conductivity, which means it does not effectively transfer heat. This makes fiberglass mat tissue a suitable material for insulating applications where heat transfer needs to be minimized, such as in building insulation or in the manufacturing of heat-resistant clothing.

- Q: How does fiberglass mat tissue compare to other types of reinforcement materials?

- Fiberglass mat tissue is a versatile reinforcement material that offers several advantages over other types of reinforcement materials. Firstly, it has excellent strength and stiffness properties, providing superior load-bearing capabilities compared to other materials. Secondly, fiberglass mat tissue is lightweight, making it easier to handle and install. Additionally, it is highly resistant to corrosion, chemicals, and moisture, ensuring long-term durability. Lastly, fiberglass mat tissue has excellent dimensional stability and is not prone to warping or shrinking, making it a reliable choice for various applications. Overall, its combination of strength, lightweight nature, durability, and dimensional stability sets fiberglass mat tissue apart from other reinforcement materials.

Send your message to us

Fiberglass Mat Tissue E-Glass Fiberglass Woven Roving, 400g, 1040mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords