Geogrids Australia - Fiberglass Geogrids for Roadbed Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

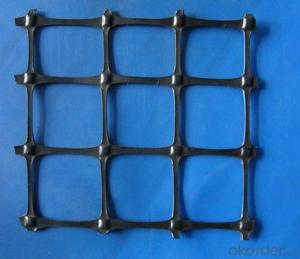

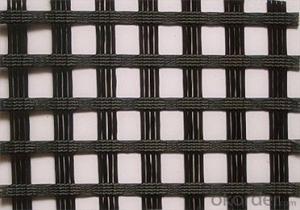

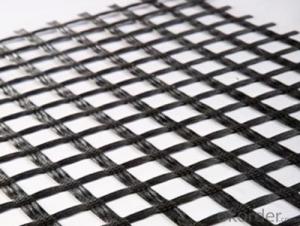

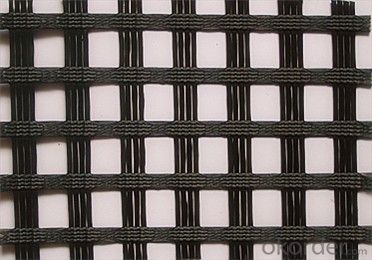

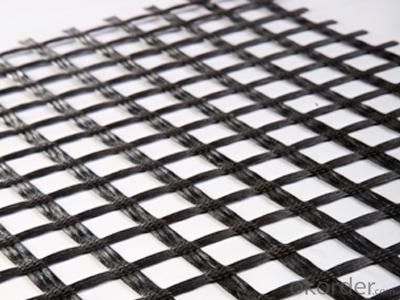

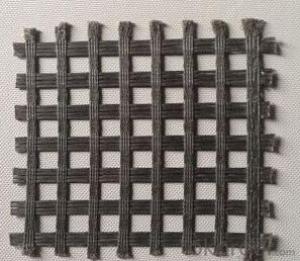

Structure of Fiberglass Geogrid:

Fiberglass Geogrid is excellent composite material used for road bed reinforcement and soft soil foundation improvement. It has become an indispensable material in treatment of reflection cracks on asphalt road surface. The products are semi-rigid mesh base made from high-strength alkaline-free glass fiber through international advanced process and subjected to surface coating. It has a high tensile strength and a lower elongation both vertically and horizontally. Moreover, it has good resistance to high and low temperature, aging and corrosion. It is widely used in Asphalt wall, railway foundation, dike slope, runway and sand harnessing.

Main Features of Fiberglass Geogrid:

fiberglass geogrid for soil reinforcement

Pavement subgrade stabilization

Area /Ground stabilization

Pavement base reinforcement

Working & load transfer platforms

Rail Track-bed stabilization

Reinforced granular foundation beds

Aluminum Alloy Wheel Hub Images

Butimen Coated Fiberglass Geogrid Specification

Glass Fiber Geogrid GGF80 Technical Specification | |||

Property | Test Method | Unit | Index |

Wide Width Tensile Strength | |||

MD | KN/M | ≥80 | |

CMD | KN/M | ≥80 | |

Elongation At Break | ≤4 | ||

Grid | MM | 25.4×25.4 | |

Width | M | 1~6 | |

Packaging | Details | ||

Roll Dimensions(W×L) | According to customer requirements | ||

Square Meters Per Roll | |||

Estimated Roll Weight | |||

It is widely used in Asphalt wall, railway foundation, dike slope, runway and sand harnessing.

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q: How about your company?

A:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q.Does your products have good qualitity?

A:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q:How long can we receive the products after purchase?

A:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: What are the differences between geogrids and geopipes?

- Geogrids and geopipes are both materials used in geotechnical and civil engineering applications, but they serve different purposes. Geogrids are typically made from high-strength polymers and are used to reinforce soils and provide stabilization. They have a grid-like structure with open spaces that allow soil to interlock with the grid, creating a stronger base. Geogrids are commonly used in retaining walls, road construction, and erosion control. On the other hand, geopipes are pipes made from various materials like plastic or concrete and are primarily used for drainage purposes. They have perforations or slots along their length, allowing water or gases to flow through. Geopipes are commonly used in subsurface drainage systems, stormwater management, and landfills to control water buildup and prevent soil saturation. In summary, the main difference between geogrids and geopipes lies in their function and structure. Geogrids provide soil reinforcement and stabilization, while geopipes facilitate drainage and water management.

- Q: Can geogrids be used in mining tailings management applications?

- Yes, geogrids can be used in mining tailings management applications. Geogrids are often employed to reinforce and stabilize tailings dams, prevent soil erosion, and improve the overall stability of the tailings impoundment. They can also assist in controlling the settlement and deformation of the tailings, providing a reliable and effective solution for tailings management in the mining industry.

- Q: How do geogrids help in reducing soil settlement?

- Geogrids help in reducing soil settlement by providing reinforcement to the soil, increasing its stability and preventing excessive movement. They distribute the load over a larger area, improving the overall bearing capacity of the soil and reducing the potential for settlement. Additionally, geogrids can restrict lateral movement of the soil particles, minimizing the chances of settlement and maintaining the integrity of the structure or foundation.

- Q: Geogrid grille read Shan or Zha?

- Geogrid - geosynthetic material used for reinforcement by a regular mesh tensile band,

- Q: Are geogrids effective in preventing soil erosion around pipelines?

- Yes, geogrids are effective in preventing soil erosion around pipelines. Geogrids provide structural support and reinforcement to the soil, preventing it from eroding and destabilizing around the pipelines. They help distribute the load and reduce the potential for soil movement, ensuring the stability and longevity of the pipeline infrastructure.

- Q: How do geogrids improve the performance of geosynthetic-reinforced walls?

- Geogrids improve the performance of geosynthetic-reinforced walls by providing tensile strength and stability to the soil structure. They act as a reinforcement material, enhancing the overall strength and load-bearing capacity of the wall. Geogrids also help to distribute the applied loads more evenly, reducing the potential for wall deformation or failure. Additionally, they prevent soil erosion and provide long-term durability to the wall system, making it more resistant to environmental factors and extending its lifespan.

- Q: How thick is the need to lay a layer of Geogrid in the new highway earthwork backfill? Specific foundation to pave the way to solve

- The road at the interface, and the next day than the Square Street shop

- Q: Can geogrids be used in reinforced earth walls?

- Yes, geogrids can be used in reinforced earth walls. Geogrids are commonly used as reinforcement materials in the construction of reinforced earth walls. They provide tensile strength and stability to the soil structure, enhancing its load-bearing capacity and overall performance.

- Q: What is the difference between unidirectional geogrid and two-way geogrid

- An efficient stress transfer mechanism is formed, so that the local load can be quickly and effectively spread to a large area of soil, so as to achieve the purpose of reducing the local failure stress and improving the service life of the project.

- Q: The geogrid is convenient for construction, time saving, labor saving, shorten the construction period and reduce maintenance cost.

- Fill enough paint to make it smooth.6, removal of leakage of tape. Then, note that all of the cracks have been properly repaired, with a fine composite material will be modified around the repair, so that it is as bright as new.

Send your message to us

Geogrids Australia - Fiberglass Geogrids for Roadbed Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords