PVC Coated Fiberglass Fabric for Electric Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Fabric with Silicone Coated for Electric Insulation

Fiberglass Fabric Description

Silicone coated fiberglass fabric is a fiberglass cloth, which possesses the properties of temperature resistance, anti-corrosion, high strength and is coated with organic silicone rubber.

Fiberglass Fabric Specification

Thickness:0.2mm-5mm

Width:100cm-150cm

Color;grey/red/silver/black

Weight(coating):130gsm-2800gsm

Model No | FSD2030 | FSD2030 | FSD2050 | FSD2100 | |

High temperature resistant(°C) | ≤280 | ≤280 | ≤280 | ≤280 | |

Low temperature resistant(°C) | ≥-40 | ≥-40 | ≥-40 | ≥-40 | |

Tensile intensity (N/50mm) | Warp | ≥1750 | ≥1750 | ≥2500 | ≥3500 |

Weft | ≥1280 | ≥1280 | ≥2100 | ≥3000 | |

Inflating burst intensity(Mpa) | ≥2.0 | ≥2.0 | ≥2.2 | ≥2.6 | |

Peeling intensity(N/m) | ≥450 | ≥450 | ≥520 | ≥600 | |

Insulation (kv/mm) | 16 | 16 | 18 | 18 | |

Weight (g/m*m) | 550-650 | 550-650 | 750-800 | 1500-1800 | |

Width(mm) | 1000±20 | 1000±20 | 1000±20 | 1000±20 | |

Thickness(mm) | 0.3-0.4 | 0.3-0.4 | 0.05-0.55 | 1.0-1.1 | |

color | Silver-gray, gray, red | lucency | Silver-gray, gray, red | Black, gray, red | |

Fiberglass Fabric Features:

1, Good performance on resisting high temperature and low temperature, -40°C-280°C;

2, High strength;

3, Ozone, oxide, light and weather aging resistance;

4, High insulation: dielectric constant:3-3.2, breakdown voltage: 20-50KV/MM;

5, Chemical corrosion resistant, oil-proofing, waterproofing (washable)

Fiberglass Fabric Application:

It has been widely used in construction, electric insulation,

chemical industry, pipeline ductile conjunction, large generating

Corrosion proofing field, machinery, metallurgy, sealing and so on.

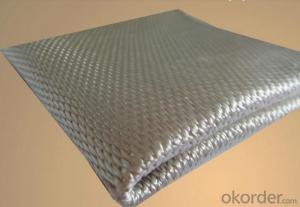

Product Show

FAQ

1.What are the characteristics of fiberglass fabric?

a)Outstanding temperature resistance(from -70°C to +260°C)

b)Excellent chemical resistance

c)Superior non-stick surface, easy to clean

d)High dielectric strength

e)Dimensional stability

f)Resistance to UV, IR and HF

g)Non-toxic

2.How many methods to weave the fabric?

Four methods to weave the fabric:

a).Plain weave: it can be used in electricity insulation materials and reinforced materials in industry, because of inseparable structure, plain and clear lines.

b).Twill weave: compared with plain weave, it is of high density, high intensity, with a soft and loose structural weave. It can be used in ordinary reinforced materials, filter materials, and painting cloth.

c) Satin weave: compared with plain weave and twill weave, it is of high density,high intensity, with a soft and loose structural weave with a good texture. It is applicable for use as a higher reinforced material in machinery.

d).Gauze weave: said lattice twist weave. It can be used in spread model curtain,resin reinforced emery wheel gray cloth and lattice embed belt.

3.Can you offer us some samples?

We are willing to offer our customers best product&service,if it's necessary we can send

you sample for test;also we welcome all you customer have a trial order.

- Q: What are the environmental impacts of using fiberglass fabric?

- The utilization of fiberglass fabric can result in various environmental consequences. Initially, the extraction of raw materials, such as silica sand, for the production of fiberglass fabric can have detrimental effects on the environment. This extraction process can disturb local ecosystems, contribute to deforestation, and release harmful pollutants into the air and water. In addition, the fabrication of fiberglass fabric necessitates a significant amount of energy, often obtained from non-renewable sources. This energy consumption contributes to the emission of greenhouse gases, exacerbating climate change. Furthermore, the production process may also generate toxic byproducts, such as formaldehyde and volatile organic compounds, which, if not managed properly, can have adverse effects on human health and the environment. Another environmental concern associated with fiberglass fabric pertains to its disposal at the end of its life cycle. Fiberglass is not biodegradable and can persist in the environment for an extended period. Improper disposal, such as sending it to landfills, can lead to the release of microplastics into the soil and water, posing a threat to wildlife and ecosystems. Furthermore, fiberglass fabric is frequently coated with resins or chemicals to enhance its performance and durability. These coatings may contain harmful substances, such as heavy metals or flame retardants, which can leach into the environment during use or disposal, potentially contaminating soil, water, and air. In conclusion, the utilization of fiberglass fabric has wide-ranging environmental impacts, including habitat destruction, energy consumption, greenhouse gas emissions, the generation of toxic byproducts, inadequate end-of-life disposal, and contamination risks. It is crucial to consider these impacts and explore alternative materials or manufacturing processes that are more sustainable and environmentally friendly.

- Q: Can fiberglass fabric be used for insulation in telecommunications infrastructure?

- Yes, fiberglass fabric can be used for insulation in telecommunications infrastructure. It is a commonly used material due to its excellent thermal insulation properties, durability, and resistance to moisture and chemicals.

- Q: Can fiberglass fabric be used for making automotive parts?

- Automotive parts can indeed be made using fiberglass fabric. Renowned for its robustness, longevity, and ability to withstand high temperatures and chemicals, fiberglass fabric proves to be an excellent choice for automotive purposes. It facilitates the creation of diverse automotive components like hoods, fenders, spoilers, and interior elements such as door panels. The flexibility of fiberglass fabric enables the production of bespoke automotive parts with intricate designs. Furthermore, its lightweight nature aids in enhancing fuel efficiency and overall vehicle performance.

- Q: What's the difference between glass fiber tape and fiberglass tape?

- Glass fiber belt is the base material, glass fiber cloth, without glue. Fiberglass is glass fiber. Glass fiber tape is called fiberglass cloth tape, a glass fiber tape, with aluminum film outside

- Q: Can fiberglass fabric be used for reinforcement in oil processing tanks?

- Yes, fiberglass fabric can be used for reinforcement in oil processing tanks. Fiberglass fabric is known for its high strength-to-weight ratio, corrosion resistance, and durability, making it an ideal material for reinforcing structures in harsh environments such as oil processing tanks. The fabric can be applied to the tanks either by wet lay-up or vacuum infusion process, ensuring proper adhesion and integration with the tank structure. Additionally, fiberglass fabric is non-conductive and non-magnetic, which makes it suitable for use in tanks containing flammable or sensitive materials. Overall, fiberglass fabric offers a cost-effective and reliable solution for reinforcing oil processing tanks.

- Q: How is fiberglass fabric laminated?

- Fiberglass fabric is laminated using a process called resin infusion. This process involves saturating the fabric with a liquid resin, which can be epoxy, polyester, or vinyl ester resin. The resin is typically mixed with a catalyst to initiate the curing process. To laminate fiberglass fabric, the fabric is first laid out on a mold or surface. The resin is then poured or applied onto the fabric, spreading it evenly across the surface. The resin is absorbed by the fabric, impregnating it completely. This process is usually done in multiple layers to achieve the desired thickness and strength. Once the fabric is saturated with the resin, it is left to cure. The curing time depends on the type of resin used and can range from a few hours to several days. During the curing process, the resin hardens, creating a solid and durable laminate. After the curing process, the fiberglass laminate may undergo additional processes such as trimming, sanding, or polishing to achieve the final desired shape and finish. These additional steps may vary depending on the specific application or product being manufactured. Overall, the lamination of fiberglass fabric involves saturating the fabric with resin and allowing it to cure, resulting in a strong and rigid composite material that is widely used in various industries, including aerospace, automotive, construction, and marine.

- Q: What is the resolution of glass fiber cloth and polyester fiber cloth?

- The advantages of this material has good coverage function, suitable for all kinds of surface defects, the effective coverage of new and old walls, ensure that the surface structure and color uniformity. The tensile strength, preventing wall cracking, strengthening effect on the wall with high quality coatings, surface static electricity accumulation, not easy to fouling dead, and clean.

- Q: Is fiberglass fabric resistant to insects?

- Yes, fiberglass fabric is generally resistant to insects.

- Q: Are there any specific storage requirements for fiberglass fabrics?

- Fiberglass fabrics have specific storage requirements. It is highly advised to keep them in a cool, dry, and well-ventilated place to prevent moisture absorption and potential fabric damage. To avoid degradation of strength and appearance, it is crucial to store them away from direct sunlight, as prolonged exposure to UV rays can be harmful. Furthermore, it is vital to keep the fabrics far from heat sources or open flames to minimize the risk of fire. Additionally, it is essential to store them separately from chemicals, solvents, or oils that may cause staining or deterioration. By storing fiberglass fabrics properly, their quality and lifespan can be maintained.

- Q: How does fiberglass fabric perform in terms of flexibility?

- Fiberglass fabric is known for its excellent flexibility. It can be easily bent, twisted, or molded into various shapes without losing its structural integrity. This flexibility makes it highly versatile and suitable for applications where movement or conformability is required.

Send your message to us

PVC Coated Fiberglass Fabric for Electric Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords