Aluminum Strips Lowes Factory Hot Sale Colour Coated Aluminium Sheet for Trailers

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

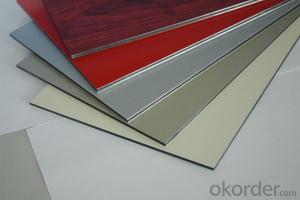

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

The first gene for aluminium tolerance has been identified in wheat. It was shown that sorghum's aluminium tolerance is controlled by a single gene, as for wheat.[112] This is not the case in all plants.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

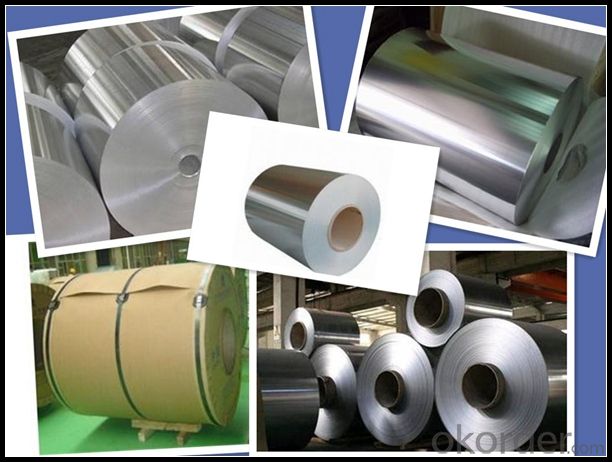

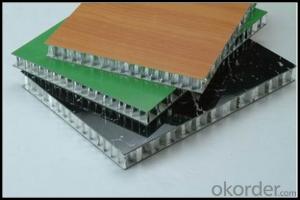

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: What specific conditions or considerations are needed when installing aluminum strips for flooring in cold weather conditions?

- <p>In cold climates, using aluminum strips for flooring requires considering thermal expansion and contraction due to temperature changes. It's crucial to allow for adequate expansion gaps to prevent buckling or warping. Additionally, it's important to use aluminum alloys with good low-temperature toughness to prevent brittleness. Proper insulation and a stable subfloor temperature are also necessary to maintain the integrity of the flooring. Always consult with a professional or manufacturer for specific recommendations tailored to the climate and project requirements.</p>

- Q: Is it possible to utilize aluminum strips for creating decorative patterns or designs on the exterior of buildings?

- <p>Yes, aluminum strips can be used to create patterns or designs on building exteriors. They are lightweight, durable, and resistant to corrosion, making them ideal for outdoor applications. Aluminum strips can be cut, bent, and shaped into various forms to create intricate designs and patterns. They can also be anodized or painted to achieve different colors and finishes, enhancing the aesthetic appeal of the building's exterior.</p>

- Q: This question asks for a step-by-step guide on how to attach aluminum strips to a roof.

- <p>To install aluminum strips on your roof, follow these steps: 1. Clean the roof surface to ensure a proper bond. 2. Measure and cut the aluminum strips to the required length. 3. Apply a high-quality adhesive or sealant to the back of the aluminum strips. 4. Position the strips on the roof, ensuring they are aligned and straight. 5. Press firmly to secure the strips in place and allow the adhesive to cure according to the manufacturer's instructions. 6. Check for any gaps or uneven areas and apply additional sealant if necessary. 7. Regularly inspect and maintain the aluminum strips to ensure they remain in good condition. Always follow safety precautions and consider hiring a professional if you are unsure about any steps.</p>

- Q: What are the potential health risks related to the use of aluminum foil?

- <p>While aluminum foil is widely used in cooking and food storage, there is limited evidence to suggest significant health risks. Some studies have linked aluminum exposure to neurological conditions like Alzheimer's, but the connection is not conclusive. The body does not absorb significant amounts of aluminum from foil, especially when used properly. However, it's important to avoid wrapping acidic or highly acidic foods in aluminum foil, as this could potentially lead to increased aluminum leaching. Overall, using aluminum foil in moderation and following proper food handling practices can minimize any potential risks.</p>

- Q: Can welding of aluminum with water-cooled DC hydrogen arc welding machine how much money

- Cheapest 3 million, slightly better, such as Panasonic's ten thousand or twenty thousand

- Q: Is it possible to use aluminum strips as a material for exterior siding on a building?

- <p>Yes, aluminum strips can be used for siding. They are known for their durability, resistance to corrosion, and low maintenance requirements. Aluminum siding is lightweight, easy to install, and comes in various colors and styles, making it a popular choice for residential and commercial buildings. It also has good resistance to harsh weather conditions and does not rot or warp, which are common issues with wood siding.</p>

- Q: This question asks for the standard cost range of aluminum strip stock, which is a type of metal material.

- <p>The typical price range for aluminum strip stock can vary significantly based on factors such as grade, thickness, width, and market conditions. As of recent market trends, prices can range from approximately $1.50 to $3.00 per pound for common grades like 1100 or 3003. However, for more specialized grades or custom specifications, the cost can be higher, potentially ranging from $2.00 to $5.00 per pound or more. It's important to note that these prices are subject to change due to fluctuations in the global aluminum market and should be verified with a supplier for the most accurate and current pricing.</p>

- Q: This question asks for an overview of the steps involved in the manufacturing of aluminum components used in vehicles.

- <p>The production process of automotive aluminum parts typically involves several key steps: material selection, design, casting or forging, machining, heat treatment, surface treatment, and quality control. Aluminum is chosen for its lightweight and high strength properties. The design phase involves creating detailed plans for the part. Casting or forging shapes the aluminum into rough forms. Machining refines these forms to precise specifications. Heat treatment enhances strength and durability. Surface treatments protect against corrosion and wear. Finally, quality control ensures each part meets industry standards before it is used in vehicles.</p>

- Q: This question asks for a list of various types of aluminum strips that are specifically used for exterior applications.

- <p>Aluminum strips used for exterior applications come in various types, each serving specific purposes. These include: 1) Architectural Aluminum Strips, used for facades and building exteriors due to their durability and weather resistance. 2) Anodized Aluminum Strips, which offer enhanced corrosion resistance and a wide range of colors for aesthetic appeal. 3) Extruded Aluminum Strips, known for their strength and customizability, suitable for structural applications. 4) Embossed Aluminum Strips, which provide a textured surface for improved grip or decorative purposes. 5) Heat Insulating Aluminum Strips, used to reduce heat transfer in exterior applications. 6) Reflective Aluminum Strips, used for safety markings or to enhance visibility in outdoor settings. Each type is chosen based on the specific requirements of the project, such as strength, appearance, and environmental conditions.</p>

- Q: This question asks for the primary applications or purposes of using aluminum strips.

- <p>Aluminum strips are primarily used in various industries due to their lightweight, corrosion resistance, and high strength-to-weight ratio. They are commonly used in construction for framing and cladding, in the automotive industry for vehicle bodies and parts, in aerospace for aircraft components, and in electrical applications for wiring and conductors. Additionally, aluminum strips are employed in packaging, such as food and beverage cans, and in the manufacturing of electronic devices and heat exchangers. Their versatility makes them a popular choice for many applications where durability and performance are required.</p>

Send your message to us

Aluminum Strips Lowes Factory Hot Sale Colour Coated Aluminium Sheet for Trailers

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords