Extruded Aluminum Sheets - Continuous Casting Aluminum Coil AA3003 HO 0.2mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

Continuous Casting Aluminium Coil is one semi-finished aluminium material. The coils are widly used in the building,decoration and aluminium circle. The alloy AA1050 is the most common alloy in the aluminium industry. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of the product

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Thickness | Width | Weight |

| AA3003 | HO | 0.2MM-3MM | 1000-1500MM | Max 3 tons |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: How do aluminum sheets perform in terms of fire resistance?

- Aluminum sheets have excellent fire resistance properties. Due to their high melting point, they can withstand extreme heat and do not contribute to the spread of fire. Additionally, aluminum forms a protective oxide layer when exposed to fire, which further enhances its fire resistance capabilities.

- Q: How much is the aluminum plate with a thick 2mm 1000*2000? Thanks

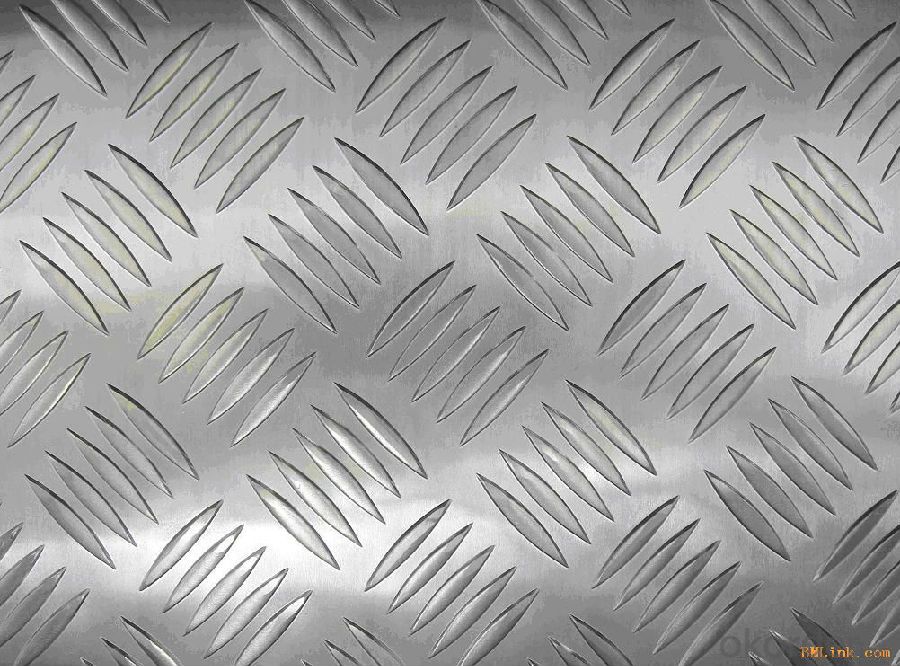

- Aluminum sheet refers to the rectangular plate made of aluminium ingot rolled and divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, middle thick aluminum plate and pattern aluminum plate.

- Q: What characteristics distinguish aluminum sheets from other types of sheets?

- <p>Aluminum sheets are lightweight, corrosion-resistant, and have excellent thermal and electrical conductivity. They are commonly used in construction, automotive, and packaging industries. In contrast, other types of sheets, such as steel sheets, are heavier and stronger but less resistant to corrosion. Plastic sheets are lightweight and flexible but have lower strength and thermal conductivity. Copper sheets offer high thermal and electrical conductivity but are more expensive and less resistant to corrosion than aluminum. Each type of sheet has unique properties that make it suitable for specific applications.</p>

- Q: Which kind of material does aluminum sheet(aluminum oxide) belong to?

- it's metal and belongs to hardware

- Q: Can aluminum sheets be bent?

- Yes, aluminum sheets can be bent as they have malleable properties that allow them to be easily shaped or formed into desired angles or curves.

- Q: Is it possible to use aluminum sheets for roofing purposes?

- <p>Yes, aluminum sheets can be used as roofing materials. They are known for their durability, lightweight, and resistance to corrosion. Aluminum is also recyclable and can be coated with various finishes to enhance its appearance and performance. It is a popular choice for both residential and commercial roofing due to its low maintenance requirements and long lifespan.</p>

- Q: What are the different surface finishes for aluminum sheets in the aerospace industry?

- Aluminum sheets are widely used in the aerospace industry for constructing aircraft structures due to their lightweight and high strength. Various surface finishes can be applied to these sheets to enhance durability, protect against corrosion, and improve appearance. Anodizing is a commonly used finish that involves coating the aluminum with a protective oxide layer through electrolysis. This process not only improves corrosion resistance but also offers a range of color options and enhances adhesive acceptance. Another popular finish is alclad, which bonds a thin layer of pure aluminum to both sides of an alloy sheet. This provides excellent corrosion resistance and allows for better bonding with composite materials. Chemical conversion coatings are also used in the aerospace industry to provide corrosion resistance and improve paint adhesion. Mechanical finishes like grinding or brushing can be used for aesthetic purposes or to prepare the surface for further treatment. Specialized finishes are employed for specific applications. For areas with high wear resistance requirements, hard anodizing creates a durable surface. For parts needing low friction or high lubricity, a Teflon coating or dry film lubricant can be applied. The choice of surface finish for aluminum sheets in the aerospace industry depends on the specific application's requirements, including factors such as corrosion resistance, adhesion properties, wear resistance, and aesthetic preferences.

- Q: Can aluminum sheets be reused or recycled after their initial use?

- <p>Yes, aluminum sheets can be recycled again after use. Aluminum is one of the most recycled materials globally due to its low cost of recycling and its ability to retain its properties even after multiple recycling processes. Recycling aluminum saves energy compared to producing new aluminum from raw materials, and it helps reduce waste in landfills.</p>

- Q: What are the different types of surface treatments available for painted aluminum sheets?

- There are several types of surface treatments available for painted aluminum sheets, including anodizing, powder coating, and laminating. Anodizing involves creating a protective oxide layer on the surface of the aluminum, providing enhanced durability and corrosion resistance. Powder coating involves applying a dry powder onto the aluminum surface and curing it to create a durable and decorative finish. Laminating involves applying a protective film onto the painted aluminum sheet, providing additional protection against scratches and UV radiation.

- Q: Are aluminum sheets suitable for decorative paneling?

- Yes, aluminum sheets are suitable for decorative paneling. They offer a sleek and modern appearance, are lightweight, durable, and resistant to rust and corrosion. Additionally, aluminum sheets can be easily manipulated and come in various colors and finishes, making them a versatile choice for decorative purposes.

Send your message to us

Extruded Aluminum Sheets - Continuous Casting Aluminum Coil AA3003 HO 0.2mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords