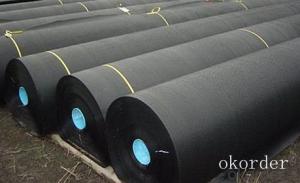

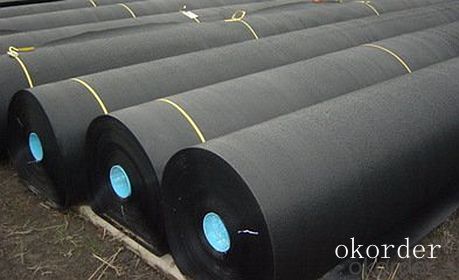

Geotextile Staples Reinforced Environmental Engineering HDPE Geomembrane Roll with High Quality for Potable Water

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Geomembrane with impermeable plastic film as a substrate, and non-woven geotextile composite made of impermeable material, which depends on the seepage properties of a impermeable plastic film performance. Is a kind of polymer chemistry flexible material, the proportion of small, extensible stronger ability to adapt to high deformation. Corrosion resistance, low temperature, frost good performance. Have better resistance to erosion, are not afraid of acid, alkali and salt erosion.

Thickness:

1mm-3mm

Length:

50-200m as customers' request

Width:

4m~9m

Standard:

ISO, CE

Feature:

Chemical Resistant

Surface:

Textured Surface

Product name:

hdpe geomembrane manufacturers

Keyword:

hdpe geomembrane manufacturers

Application

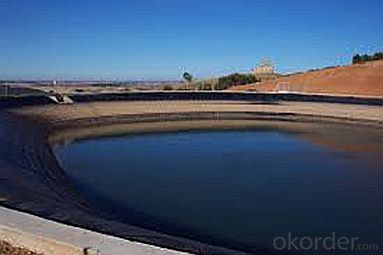

1. high quality hdpe geomembrane use in agriculture

1. high quality hdpe geomembrane use in agriculture farm

3. high quality hdpe geomembrane use in shrimp ponds orLotus

4. high quality hdpe geomembrane use in Slope protection impervious

5. high quality hdpe geomembrane use in Landfill anti-seepage

6. high quality hdpe geomembrane use in Agricultural water reservoir:

7. high quality hdpe geomembrane for roof seepage control

Technical specifications of HDPE geomembrane:

Our Service

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Are geotextiles commonly used in rainwater harvesting systems?

- Yes, geotextiles are commonly used in rainwater harvesting systems. Geotextiles act as a filtration layer, preventing the entry of debris and sediment into the harvesting system while allowing water to pass through. This helps to maintain the quality of collected rainwater and prevents clogging or damage to the system.

- Q: Geotextile production process

- General spunbond, acupuncture, weaving, weaving, spunlace and other processes,

- Q: Whether the geotextile filter layer includes a plastic mesh

- Hello, geotextile can be used as a separate filter and grid sand with as a filter layer, Huazhi geotextile material manufacturers for you to answer

- Q: U400 geotextile u400 what it means

- Is not 400g / ㎡ of geotextile? My company specializes in the production of geotextiles, details (hand) to see capital (machine) material

- Q: What are the design considerations for geotextile-reinforced slopes?

- Some key design considerations for geotextile-reinforced slopes include selecting the appropriate type and strength of geotextile, considering the slope angle and height, evaluating the soil conditions and stability, determining the required length and spacing of reinforcement layers, ensuring proper installation and quality control, and accounting for factors such as water drainage and vegetation establishment. Additionally, the design should consider the long-term durability and maintenance requirements of the reinforced slope.

- Q: Manufacture of geotextile machinery

- Non-woven needle machine, I am specializing in the production of geotextiles

- Q: Can geotextiles be used in green roof drainage systems?

- Yes, geotextiles can be used in green roof drainage systems. Geotextiles are commonly used as a filtration layer to separate the drainage material from the growing medium in green roofs. They help to retain moisture, prevent clogging, and enhance the overall performance of the drainage system.

- Q: Geotextile puncture test standard

- Staple stitch filament piercing filament woven weaving

- Q: What are the standards and regulations governing geotextiles?

- The standards and regulations governing geotextiles vary depending on the country and its specific requirements. However, some common standards and regulations followed globally include those set by the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM). These standards typically cover aspects such as geotextile materials, design guidelines, testing methods, and performance requirements. Additionally, specific regulations related to geotextiles may exist at the national or regional level to ensure their proper use and compliance with environmental and safety standards.

- Q: How are geotextiles affected by mechanical stress?

- Geotextiles are significantly affected by mechanical stress as they undergo deformation and potential damage due to external forces or loads. The stress can cause the geotextile to stretch, tear, or even rupture, affecting its overall performance and functionality. Therefore, it is essential to consider the mechanical stress factors when designing or implementing geotextile applications to ensure their long-term durability and effectiveness.

Send your message to us

Geotextile Staples Reinforced Environmental Engineering HDPE Geomembrane Roll with High Quality for Potable Water

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords