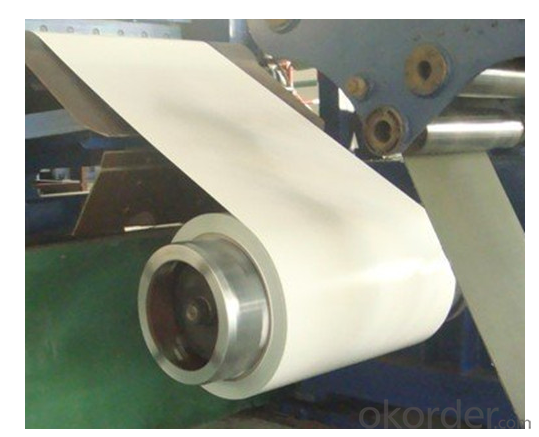

EN10169 PREPAINTED GALVANIZED STEEL COIL

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Brief Introduction

EN10169 Prepainted galvanized steel coil ,with Gi as base metal after pretreatment ( degrease and chemical treatment) and liquid dope with several layers of color then after firing and cooling finally the plate steel is called Pre-painted galvanized steel is good capable of decoration ,molding corrosion resistance

Product Features

Excellent process capability

Smooth and flat surface

Workability durability

Excellent heat resistance performance

High Strength

Good formability

Good visual effect

Product Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

FAQ

1. How long will we receive the goods ?

45days after receiving workable L/C

2. how do you control the quality ?

we have our own quality control department ,we will arrange QC person to see the production line ,when goods finish ,before shipment ,our QC person will check the quality as per our test report request ,if the goods is ok ,then we issue the test report ,and we allow the goods shipping ,otherwise will not allow ship the goods.

- Q: I have never owned a non-stainless steel chef's knife and have been looking at some to buy recently, but all of them have various degrees of wear and use. They say that the wear is normal for non-stainless steel knives, but how can I tell if it is too much wear, or if the blade is clean?

- cold rolled steel waers as you carve meat. If the blad if to thin you may want a better one. Utica knife in utica N.Y. made them up to about 10 years ago and i still buy them at auctions.

- Q: What are the typical lead times for ordering steel coils?

- The typical lead times for ordering steel coils can vary depending on several factors, including the supplier, the quantity and specifications of the coils, as well as the current market conditions. However, on average, lead times can range from a few weeks to a couple of months. It is always recommended to contact the specific supplier for more accurate information regarding lead times.

- Q: Can't find it- this is for a physics experiment for youngs modulus done with a steel wire.

- It depends on the type of steel and how the wire was made (e.g. whether it was drawn hot or cold, whether it was heat treated after it was drawn, etc). For mild steel the elastic limit is about 400 MPa. Note this is not the same as the breaking stress for the wire which will typically be significantly higher for a ductile material like steel. If you want to measure a stress-strain curve to find youngs modulus, make sure you measure several points at stresses below the elastic limit - for example try increasing the stress in increments of about 50 MPa.

- Q: I would like to buy a new cold steel recon 1 folding knife. My concern is the knife is made in Taiwan, will the quality of blade/overall make is lower quality compare with those made in US/JAPAN? The plan is use as an EDC, any good suggestion with similar style? Most important to me is reliability, 2)sharpness, 3) maintance than 4)cost. Anyone can point me into right direction? Please share, Thanks in advance.

- Cold okorder /

- Q: What are the different thickness tolerances for steel coils?

- The specific requirements and industry standards can cause the thickness tolerances for steel coils to vary. There are several common thickness tolerances for steel coils: - The standard tolerance ranges from ±0.005 inches to ±0.010 inches. This means that the actual thickness of the steel coil can deviate within this range from the specified thickness. - Stricter tolerances, known as tighter tolerances, may be necessary in certain cases, particularly for critical applications or industries. These tighter tolerances can range from ±0.002 inches to ±0.005 inches, ensuring more precise thickness control for the steel coils. - Custom thickness tolerances can be defined to meet the specific needs of a project or customer. These custom tolerances can be looser or tighter than the standard or tighter tolerances, depending on the application and desired precision level. It is important to consider that different industries and applications may have their own unique tolerance requirements. For example, industries such as automotive or aerospace may demand tighter tolerances due to the critical nature of their applications, while other industries may accept looser tolerances. Additionally, the specific type of steel being used can also affect the acceptable thickness tolerances. Therefore, consulting the relevant industry standards and specifications is crucial in determining the appropriate thickness tolerances for steel coils in a particular application.

- Q: What are the different methods of storing steel coils?

- There are various ways to store steel coils depending on the specific requirements and limitations of the storage facility. Some commonly used methods include: 1. Stacking: Steel coils are stacked on top of one another in a stable manner, maximizing vertical space. However, careful stacking is necessary to maintain stability and prevent damage. 2. Block stacking: Steel coils are arranged in blocks, with each coil placed directly on top of another. The blocks are then stacked to optimize space. This method provides stability and easy access to individual coils, but additional equipment may be needed to prevent damage. 3. Coil cradles: These are specialized racks or frames designed to hold steel coils horizontally. They offer support and prevent rolling or shifting, making them suitable for smaller coils or when quick access is required. 4. Coil saddles: U-shaped frames specifically designed to hold and support steel coils vertically. They are often used in conjunction with block stacking or stack storage methods, providing stability and preventing rolling or collapsing. 5. Coil racks: Steel structures designed to hold multiple coils in an organized manner. They can have multiple levels or tiers, maximizing space efficiency. Coil racks are typically used for larger coils and can be customized for specific dimensions. 6. Automated storage systems: In large-scale facilities, mechanical systems such as coil cranes or coil carousels are used to transport and store steel coils. These systems ensure efficient and fast retrieval in high-volume operations where frequent coil handling is necessary. When determining the most suitable storage method for steel coils, factors such as size, weight, accessibility, and environmental conditions should be considered. Proper handling, labeling, and regular inspections are also crucial for maintaining the integrity and longevity of the stored coils.

- Q: How are steel coils used in the manufacturing of electrical equipment?

- Steel coils are commonly used in the manufacturing of electrical equipment as they serve as a key component in transformers and motors. These coils are typically made of high-quality steel and are tightly wound to create an electromagnetic field when an electric current passes through them. This allows for efficient power transmission, voltage regulation, and electromagnetic induction, which are essential functions in various electrical devices.

- Q: What are the different methods of surface cleaning for steel coils?

- There are multiple options available for cleaning the surface of steel coils, and the choice of method relies on specific requirements and conditions. 1. Mechanical Cleaning: To physically eliminate dirt, rust, or other contaminants from the surface of steel coils, mechanical tools like wire brushes, sanding discs, or abrasive pads are used. It is commonly employed for light cleaning and can be done manually or with the assistance of automated equipment. 2. Chemical Cleaning: By using various cleaning agents or solvents, chemical cleaning dissolves or loosens contaminants from the surface of steel coils. This method effectively removes oil, grease, or stubborn dirt. The selection of chemicals depends on the type of contaminants and the desired level of cleaning. It is crucial to adhere to safety guidelines and use appropriate protective equipment when utilizing chemical cleaners. 3. Power Washing: High-pressure water jets are utilized in power washing or pressure washing to eliminate loose particles, dirt, or contaminants from the surface of steel coils. This method is effective for extensive cleaning and can be combined with chemical cleaners for better results. Adjusting the water pressure according to the surface type and using suitable nozzles is important to prevent damage. 4. Pickling: Pickling is a chemical cleaning method that involves immersing steel coils in an acidic solution, typically a mixture of hydrochloric acid and sulfuric acid. This process eliminates scale, oxides, and other impurities from the steel's surface. Pickling is frequently employed for heavy-duty cleaning and preparing steel coils before further processing or coating. 5. Electrolytic Cleaning: Electrolytic cleaning employs an electric current to remove contaminants from the surface of steel coils. The coils are submerged in an electrolyte solution, and the application of direct current causes the contaminants to dissolve or dislodge. This method is highly effective for eliminating rust or corrosion and can be used in conjunction with other cleaning methods. When choosing the appropriate surface cleaning method, it is vital to consider factors like the type and condition of the steel coils, the required level of cleanliness, and any specific industry standards or regulations. Regular maintenance and cleaning are essential to ensure the longevity, performance, and corrosion resistance of steel coils.

- Q: aLSO, DOES STEEL C45 REFER TO THE CARBON IN IT?ALSO, WHAT IS AIRCRAFT GRADE PLYWOOD AND WHERE DOES ONE GET IT

- chromium nickle steel aka stainless steel exact amount of chrome and nickle will determine type/grade numbers Check the google for steel type/grade Never head of aircraft grade, however,, there is marine grade - normally baltic birch with waterproof glue and no defects i.e. knots, etc. Very strong (also quite expensive) but worth it for the correct applications

- Q: I just started playing guitar last year. I never changed the chords. When my sister started taking guitar lessons her teacher said that she needed to change the chords. When i bought the guitar it came with steel strings but i bought nylon strings because they are easier on the fingers. The problem is i already tuned up the guitar but it sounds really bad like if it was not tuned. What can i do about this?

- Both are designed deferentially, they have their own sound and music distinction and so as their string you should use what is appropriate to them.

Send your message to us

EN10169 PREPAINTED GALVANIZED STEEL COIL

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords