Electric PVC Ball Valve Válvula de Bola de PVC Eléctrico

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Plywood case or buyer request |

| Delivery Detail: | Negotiation |

Specifications

1. Pressure: 0.6mpa-1.0mpa

2. Voltage:AC220V AC110V AC380V DC12V DC24V DC110V

3. Size:DN10-100

4. Type: on/off ;I/O:4-20mA

1.Size:1/2"-4"

2.Standard:DIN,JIS,ANSI

3.End connection:SOCKET

4.Working Pressure:0.2-1.0Mpa

5.Sealing Oring:EPDM/VITON

UPVC union ball valve

1.Size:1/2"-4"

2.Body Material Temperature Range(oC)

PVDF -40-140

RPP -14-90

UPVC -14-70

CPVC -20-95

PPH -14-90

3.Working Pressure:0.2-0.6Mpa

4.Standard:DIN,ANSI,JIS

5.Color:White,grey,red

6.Actuator/operation:Manually operated,pneumatically operated and motorized

7.Valves are widely used in chemical industry,petroleum,chlorine/alkaline,metallurgy,pharmacy,dyeing,foodstuff,environmental protection and pure water etc..

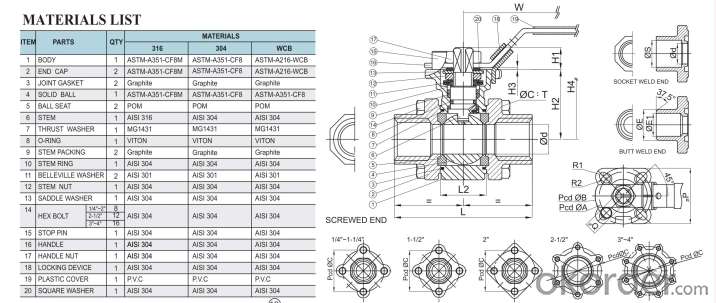

8.Part material sheet

No. | Part Name | Material |

1 | Body | FRPP,PVDF,PPH,CPVC,UPVC |

2 | Ball | FRPP,PVDF,PPH,CPVC,UPVC |

3 | Press | FRPP,PVDF,PPH,CPVC,UPVC |

4 | Union(SOCKET,THREADED) | FRPP,PVDF,PPH,CPVC,UPVC |

5 | Fight Tight Nut | FRPP,PVDF,PPH,CPVC,UPVC |

6 | Sealing | PTFE |

7 | ORing | EPDM/VITON.FPM |

FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Who knows why the ball valve is divided into a piece of ball valve, two pieces of ball valve, three pieces of ball

- There is, of course, a difference,This is according to the structure of the valve body,The difference between them is whether they are easy to disassemble, for example, the three piece of ball valve is easiest to disassemble.

- Q: What does "ball Q41F-16" mean?

- Q- ball, 4- flange connection, 1- DC channel, floating ball, F- sealing material for fluorine plastic, 16- nominal pressure of 16 kg, the valve body material for gray cast iron. If you want to know the details of the valve named model establishment, can refer to the JBT-308-2004 standard.

- Q: How many points of the ball valve, corresponding to a bit valve? Is there a detailed conversion form? How to convert? What is the basis for the conversion? Is there a formula? Big 50, pleaseHow many points of the ball valve, corresponding to a bit valve? Is there a detailed conversion form? How to convert? What is the basis for the conversion? Is there a formula? Beg you greatly! Don't forget the detailed form!

- No detailed conversion forms are required. How many inches is the representation of inches?.In English, 12 inches are 1 feet, 1 inches =8 cents.So: 1/2 "ball valve, =4 sub ball valve, 1/4" ball valve, =2 sub ball valve, 3/8 ball valve, =3 sub ball valve, and so on.Just a simple conversion relationship.

- Q: What does "DN PN" mean? DN25 PN18 stands for what is the thickness? With the usual said 4 in charge of what's the relationship?

- Nominal diameter (nominal, diameter), also known as the average diameter (mean, outside, diameter).DN is nominal diameter, nominal diameter (or nominal diameter), that is, all kinds of pipe and pipe accessories of universal caliber. The pipes with the same nominal diameter can be connected with each other, so they are interchangeable. It is not the actual diameter or diameter of the pipe, although its value is close to or equal to the diameter of the pipe.In order to connect the pipe and pipe fittings in a unified way, nominal diameter (also called nominal diameter, nominal diameter) is adopted. For example, welded steel pipes can be divided into thin wall steel pipes, ordinary steel pipes and thickened steel pipes according to their thickness. Its nominal diameter is neither external diameter nor internal diameter, but a nominal size similar to the diameter of the ordinary steel pipe. Each nominal diameter corresponds to an outer diameter, and the inner diameter varies with the thickness. Nominal diameter can be expressed in metric mm, also available in English in. With nominal diameter pipeline accessories, meaning with tube.Nominal outer diameter is expressed by DN, refers to the outer diameter of the pipe. Such as the outer diameter of 32mm PVC-U pipe can be expressed as dn32. The specification of PVC-U pipe for building drainage is indicated by DN (nominal outer diameter) * e (pipe wall thickness) (GB-T, 5836.1-2006).

- Q: Flange ball valve Q41P3-150C2, DN50, RF, WCB/316 hardening, each letter number represents what?

- P3, C2? Uncultured, I know P and C, P is the sealing surface material boroning steel is above C, WCB or A105But you Tidianyijian pressure 15MPa, RF surface is not well, the best is to use RJ flange

- Q: I've seen a lot of hot water projects. Why do most of them use globe valves, and ball valves are seldom used?.Globe valves have those benefits compared to ball valves (because the cut-off valve is more expensive, I think it is more expensive and more useful. It must have some advantages in that respect.)Is the stop valve more durable than the ball valve?What are the specific differences between the two PPR valves?

- Yes, now the globe valve is more than the ball valve with more people, and its main or cut-off valve, a lot of adjustability, and most can be universal.Specific differences are as follows:Valve opening and closing parts are plug shaped valve, sealing surface flat or cone, fluid along the centerline of the valve for linear motion. Stem movement in the form of lifting rod (stem lifting, hand wheel not lifting), but also lifting, rotating rod type (hand wheel with the valve stem to rotate up and down, nut on the valve body). Valve is only applicable to fully open and fully closed, does not allow for adjustment and throttle.The cut-off valve is a forced seal type valve, so when the valve is closed, the valve must be applied to the pressure, to force the sealing surface is not leaking. When the medium into the valve six from the bottom of the valve, the operating force required to overcome the resistance, is the stem and the packing friction and pressure generated by the media thrust force than the valve off the valve opening force, so the diameter of the valve stem, otherwise it will bend the stem top of the fault. In recent years, the emergence of self sealing valve, globe valve replaced by medium flow on the top of the valve into the valve chamber, then in the medium under pressure, the valve off a small force, and force open the valve, stem diameter can be reduced accordingly. At the same time, in the role of media, this form of valve is also more stringent. China's valve "three to" has stipulated that the flow direction of the cut-off valve should be top-down.

- Q: What is the difference between ball valve and plug valve?

- The main advantages of plug valves are as follows:Suitable for frequent operation, quick and easy opening and closing.Fluid resistance is small.The utility model has the advantages of simple structure, relatively small volume, light weight and convenient maintenance.Good sealing performanceFree from the direction of installation, the flow direction of the medium can be arbitrary.No vibration, little noise.Plug valve installation and maintenance should pay attention to the following matters:Leave the valve handle in a rotating positionCannot be used as throttling.

- Q: Our factory has part of the ball valve in the direction of movement and normal ball valve is the opposite direction: anti clockwise for the turn off, clockwise. Excuse me, what's the reason for this?Excuse me, is this because the valve body installs the reason of the contrary or the reason, the ball valve is thus designed?Are there any positive and negative points when the ball valve is installed?

- Ball valve is 90 degrees switch, you may put the handle of the wrong position, change 90 degrees, try it

- Q: Structure design principle of fire ball valve

- The purpose of fire protection structure design of valve seat is:(1) effective guarantee in the fire accident, the upstream pressure medium as little as possible into the body cavity through the valve seat, thereby causing internal leakage and leakage. Ensure that fire accidents are not expanded by fire before the firemen arrive at the scene of the accident. After the firemen arrive at the scene, fire equipment can be used to quickly suppress the fire and eliminate fire accidents.(2) to make the structure of the product meets API6D specifications. Fire proof can be obtained through fire test.Fireproof design of valve seat:Set graphite in metal fire valve seat and valve body sealing rings; sealing set fireproof metal in the metal valve seat and ball room. The structure is shown in Figures 1 and 2.

- Q: What does copper ball valve mean by "1/2"?

- 1/2 is inch inch, which is what is usually called "valve", and the caliber is "DN15". You can see the contrast chart of the valve diameter and inch.

Send your message to us

Electric PVC Ball Valve Válvula de Bola de PVC Eléctrico

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords