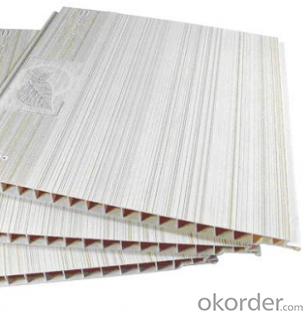

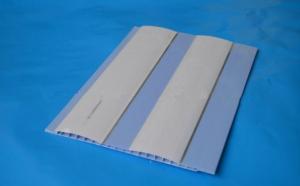

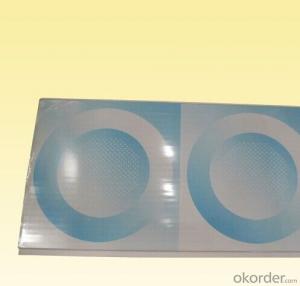

Easy Install Decorative PVC Wall Panels for Wall Cladding

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Easy Install Decorative PVC Wall Panels for Wall Cladding

Specification:

1.Width: 0.915,1,1.22,1.56,2.05m

2.Thickness: 1~40mm

3.Colors: as your requirementThickness: 1mm~25mm

Good features:

1. Light weight,good tenacity, high rigidity

2. Fireproof and flame retardant

3. Good insulation

4. No sopping, no deformation

5. Easily to processed

6. Good plasticity, being an excellent thermoform material

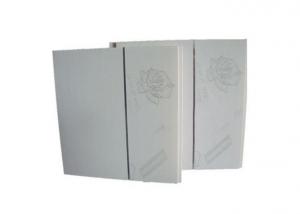

7. Sub-light surface and elegant vision

8. Anti-chemical corrosion

9. Suitable to silk screen printing

10. With imported dyes, unfading and anti-aging

Applications:

Advertising: signs, exhibition stands, routing sheets, etc..

Industry: Manufacturing industries, control cabinets, etc., and warning signs.

Construction: Wall cladding, sandwich panels, interior decoration etc.

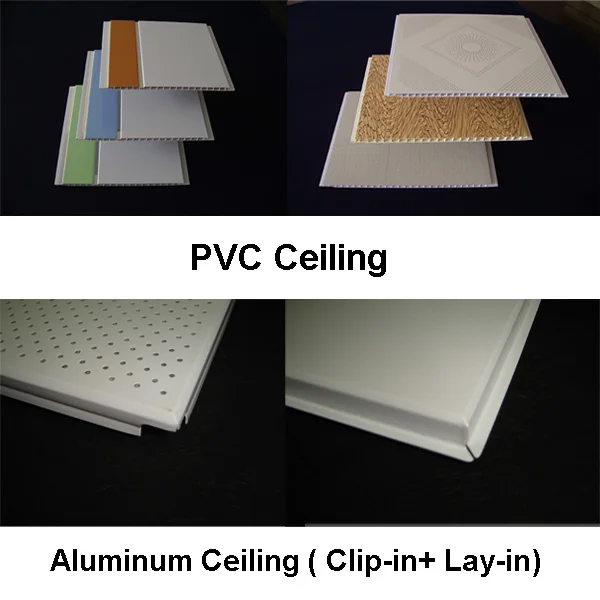

pvc ceiling tiles pvc panels for sale

PVC Sheet-applied treatments:

Materials processing: Cut; Drilling; Milling; nail etc.

Heat application: wisting, bending; Resource work; Heat styling

Other: Digital Printing; Application of alternative soil; Application sheets; Painting

Produce Arrange:

PVC foam sheet | |||||

Specifications | Thickness(mm) | Densityg/cm3) | MOQ(pc) | Color | Application |

0.915*1.83 | 1--10 | 0.5-0.8 | 1000 | White | Sign board |

1.22*2.44 | 1--10 | 0.5-0.8 | 500 | White/Colored | |

1.56*3.05 | 1--10 | 0.5-0.8 | 500 | White/Colored | |

2.05*3.05 | 1--10 | 0.6-0.9 | 500 | White/Colored | |

PVC Celuca Sheet | |||||

Specifications | Thicknessmm | Densityg/cm3) | MOQ(pc) | Color | Application |

1.22*2.44 | 4--40 | 0.5-0.8 | 500 | White | Furniture |

1.56*3.05 | 8--40 | 0.6-0.8 | 500 | White | Furniture |

PVC rigid sheet | |||||

1.22*2.44 | 1--3 | 1.42 | 500 | Sign board |

Our main products in CNBM:

pvc ceiling tiles pvc panels for sale

- Q: PVC trim panel how much money a square meter ah? What brand?

- This is not sub-brand, but also depends on the thickness

- Q: Bamboo flooring and PVC flooring which is good

- Not a level of things that are not comparable, you can ask PVC and laminate flooring which is good

- Q: How to bend the pvc board into the desired shape, that is, a plexiglass-like plate. To process the DIY accessories. I want to bend it into the desired curvature or drum shape. How to get. Or burning it, it will turn black. Ugly. Do you use a hair dryer or do you use other methods? Hot water is really useful. Is there any other way? Do not work with a microwave oven?

- To be processed accessories ~ ~ can only be done with a wooden barrel-shaped mold ~ ~ to pay attention to the size of the mold to do a little smaller than the DIY ~ ~ DIY you do not have to say how much you do it ~ and then home inside the Yuba Of the removal of the heater ~ ~ light directly on the PVC board ~ lights and board from about ten centimeters ~ around the high-power lights and the top with the board around to try not to let the heat away ~ ~ ten minutes to observe the soft Time and then around the mold pressure cold water cooling quickly.

- Q: Who has pvc foam board performance indicators ah?

- There is no standard how good, we set the standard ah, what is what it is.

- Q: Production of PVC foam board of raw materials are what ah? What is the role of ah?

- Stabilizer: In the PVC foam sheet production process, in order to make the material fully plasticized, the material temperature is higher; and the plate mold cross-section width, long runner, especially the crust foam sheet mold section is longer, In addition, the blowing agent in the decomposition process also produce decomposition heat, these factors require stabilizers must have sufficient thermal stability. In order to ensure product quality, long-term stable production.

- Q: Are PVC environmentally friendly?

- That is in line with international environmental standards, non-polluting or less pollution of PVC materials. PVC is polyvinyl chloride, English referred to as PVC (Polyvinyl chloride), vinyl chloride monomer (vinyl chloride monomer, referred to as VCM) in the peroxide, azo compounds and other initiator; or in the light, heat by free radical polymerization Reaction mechanism polymerization of the polymer. Vinyl chloride homopolymer and vinyl chloride copolymer collectively referred to as vinyl chloride resin. The material is a non-crystalline material. PVC materials in the actual use of often added stabilizers, lubricants, auxiliary processing agents, colorants, impact agents and other additives. With non-flammability, high strength, weather resistance and excellent geometric stability. PVC has a strong resistance to oxidants, reducing agents and strong acids. However, it can be strongly oxidized acid such as concentrated sulfuric acid, concentrated nitric acid corrosion and does not apply with aromatic hydrocarbons, chlorinated hydrocarbons in contact with the occasion.

- Q: Pvc material plate how to weld?

- 10mm plate first to play around the mouth, the board fixed, and then double root pvc welding rod welding, welding at least three times, the best six times, the weld to protrude, the best between the electrodes without pores.

- Q: What kind of plastic plate does the water tank make

- Do water tanks are generally made of PVC plastic sheet. PVC, English referred to as PVC (Polyvinyl chloride), vinyl chloride monomer (vinyl chloride monomer, referred to as VCM) in the peroxide, azo compounds and other initiator; or in the light and heat under the free radical polymerization mechanism Polymerized polymer. Vinyl chloride homopolymer and vinyl chloride copolymer collectively referred to as vinyl chloride resin. PVC is an amorphous structure of the white powder, the degree of branching is relatively small, the relative density of 1.4 or so, the glass transition temperature of 77 ~ 90 ℃, 170 ℃ or so began to decompose, the stability of light and heat poor, above 100 ℃ or for a long time Sun exposure, it will break down and produce hydrogen chloride, and further automatic catalytic decomposition, causing discoloration, physical and mechanical properties are rapidly declining, in practical applications must be added stabilizer to improve the stability of heat and light.

- Q: Pvc board why the sun will be deformed directly

- 60-80 ℃ or so

- Q: Snow board is not pvc board, how the difference ah?

- Chevrolet board is also called the Andy board is PVC free foam board. Points: free hair plate and crust free foam board two.

Send your message to us

Easy Install Decorative PVC Wall Panels for Wall Cladding

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords