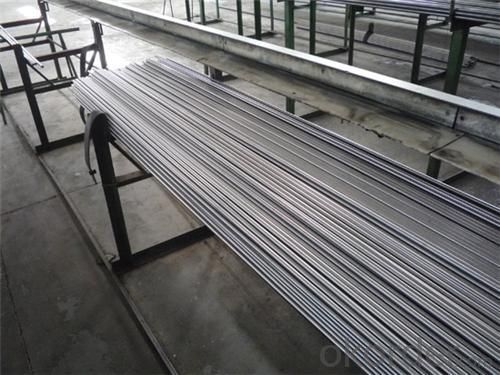

durable and Reliable sus 309 stainless steel bar with quick delivery made in china

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: Can stainless steel pipes be insulated with polylactide-co-glycolide?

- No, stainless steel pipes cannot be insulated with polylactide-co-glycolide as it is a biodegradable polymer commonly used in medical applications, and it may not provide sufficient insulation for pipes.

- Q: What is the difference between 304 and 316 stainless steel pipes?

- The main difference between 304 and 316 stainless steel pipes lies in their composition. While both alloys are corrosion-resistant, 316 stainless steel contains higher levels of molybdenum and nickel, making it more resistant to pitting and crevice corrosion in chloride environments. Additionally, 316 stainless steel offers better overall corrosion resistance and increased strength at elevated temperatures compared to 304 stainless steel pipes.

- Q: Are stainless steel pipes suitable for oil refineries?

- Yes, stainless steel pipes are suitable for use in oil refineries. Stainless steel is highly corrosion resistant, which is essential in an environment with high levels of corrosive substances such as crude oil and various chemicals used in refining processes. Stainless steel pipes are capable of withstanding high temperatures and pressures, making them ideal for transporting oil and gas within the refinery. Additionally, stainless steel pipes have low maintenance requirements and a long lifespan, reducing the need for frequent replacements and minimizing downtime. Overall, stainless steel pipes provide the durability, reliability, and resistance to corrosion necessary for the demanding conditions of oil refineries.

- Q: Can stainless steel pipes be insulated with polystyrene sulfonate?

- Yes, stainless steel pipes can be insulated with polystyrene sulfonate. Polystyrene sulfonate is a commonly used material for insulating pipes due to its thermal insulation properties and resistance to moisture and chemicals. It can be easily applied to stainless steel pipes to provide effective insulation and prevent heat loss or gain.

- Q: What is the difference between seamless and hot-rolled stainless steel pipes?

- Seamless and hot-rolled stainless steel pipes are commonly utilized in various industries due to their durability and resistance to corrosion. Nonetheless, there exist notable distinctions between the two. 1. Manufacturing process: Seamless stainless steel pipes are produced through a technique known as piercing, which involves heating a solid billet and piercing it to create a hollow tube. Conversely, hot-rolled stainless steel pipes are formed by heating a solid billet or slab and subsequently rolling it into the desired shape. 2. Appearance: The manufacturing process of seamless stainless steel pipes results in a smooth and uniform appearance. In contrast, hot-rolled stainless steel pipes possess a rough and scaly surface due to the rolling process. 3. Strength: Generally, seamless stainless steel pipes exhibit greater strength compared to their hot-rolled counterparts. This is attributed to the additional processes such as cold drawing or cold rolling that seamless pipes undergo, which enhance their strength. 4. Wall thickness: The manufacturing process of seamless stainless steel pipes allows for a more precise wall thickness. Conversely, hot-rolled stainless steel pipes may have variations in wall thickness due to the rolling process. 5. Cost: Hot-rolled stainless steel pipes are typically more cost-effective than seamless pipes. This is because the manufacturing process of hot-rolled pipes is simpler and requires less time and energy. 6. Availability: Hot-rolled stainless steel pipes are more readily accessible in the market compared to seamless pipes. This is due to the faster manufacturing process of hot-rolled pipes, which allows for quicker production and availability. In conclusion, while both seamless and hot-rolled stainless steel pipes offer exceptional corrosion resistance and durability, they differ in terms of manufacturing process, appearance, strength, wall thickness, cost, and availability. The choice between the two will depend on the specific requirements and preferences of the application or industry in which they will be utilized.

- Q: What is the difference between 304J4 and 316J4 stainless steel pipes?

- The main difference between 304J4 and 316J4 stainless steel pipes lies in their composition and corrosion resistance properties. 304J4 stainless steel contains a higher percentage of chromium and nickel, making it more resistant to corrosion in general environments. On the other hand, 316J4 stainless steel has additional molybdenum content, which enhances its resistance to corrosive agents such as chlorides, making it particularly suitable for applications in marine environments or those involving exposure to chemicals. Therefore, the choice between these two types of stainless steel pipes depends on the specific requirements of the intended application in terms of corrosion resistance.

- Q: Can stainless steel pipes handle acidic or alkaline fluids?

- Yes, stainless steel pipes can handle both acidic and alkaline fluids. Stainless steel is known for its excellent corrosion resistance, which makes it highly suitable for handling aggressive substances. It contains chromium, which reacts with oxygen to form a thin protective layer on the surface of the steel, preventing further corrosion. This passive layer is stable in both acidic and alkaline environments, providing long-term protection against corrosive fluids. However, the corrosion resistance can vary depending on the specific grade of stainless steel used and the concentration and temperature of the fluids being transported. It is important to select the appropriate grade of stainless steel and consider factors such as temperature, concentration, and potential exposure to other corrosive substances when choosing stainless steel pipes for handling acidic or alkaline fluids.

- Q: How do stainless steel pipes compare to concrete pipes?

- Stainless steel pipes and concrete pipes each have their own advantages and disadvantages, and their suitability for specific applications may vary. Stainless steel pipes are known for their durability, corrosion resistance, and high strength-to-weight ratio. They can withstand extreme temperatures, making them ideal for applications that involve high-pressure fluids or gases, such as in the oil and gas industry. Stainless steel pipes are also commonly used in food processing, chemical plants, and wastewater treatment facilities due to their hygienic properties and resistance to chemicals. Additionally, stainless steel pipes have a smooth interior surface, which reduces friction and allows for efficient fluid flow. On the other hand, concrete pipes are known for their strength, longevity, and resistance to external loads. They are commonly used in sewer systems, stormwater drainage, and culverts due to their ability to withstand heavy traffic loads and high groundwater pressures. Concrete pipes are also fire-resistant and provide excellent insulation, making them suitable for applications where fire protection is crucial. In terms of cost, stainless steel pipes are generally more expensive than concrete pipes. However, stainless steel pipes require minimal maintenance and have a longer lifespan, which can offset the initial cost. Concrete pipes, although cheaper, may require more frequent repairs and have a shorter lifespan. Ultimately, the choice between stainless steel pipes and concrete pipes depends on the specific requirements of the project, including factors such as the intended application, environmental conditions, budget, and lifespan expectations. Consulting with a professional engineer or specialist in pipe materials can help ensure the selection of the most appropriate pipe material for a particular project.

- Q: What is the difference between 304 and 304H stainless steel pipes?

- The carbon content is the main factor distinguishing 304 and 304H stainless steel pipes. Both materials consist of iron, chromium, and nickel, but 304H stainless steel has a higher carbon content compared to 304 stainless steel. This increased carbon content in 304H enhances its strength and resistance to deformation at high temperatures, making it more suitable for applications involving elevated temperatures. The higher carbon content in 304H stainless steel pipes also improves their ability to resist sensitization during welding. Sensitization refers to the formation of chromium carbides at the grain boundaries, which can lead to intergranular corrosion and reduced mechanical properties. By incorporating a higher carbon content, 304H stainless steel pipes can effectively resist this sensitization phenomenon and maintain their structural integrity even at high temperatures. Both 304 and 304H stainless steel pipes exhibit excellent corrosion resistance, good weldability, and high strength. They find extensive use in various industries, including oil and gas, chemical, food processing, and pharmaceuticals. However, it is worth noting that 304H stainless steel pipes are typically recommended for applications requiring high-temperature strength, while 304 stainless steel pipes are more commonly used for general-purpose applications. In conclusion, the carbon content distinguishes 304 and 304H stainless steel pipes. 304H stainless steel pipes have a higher carbon content, which enhances their high-temperature strength and resistance to sensitization during welding. These differences should be taken into account when selecting the appropriate stainless steel pipe for a specific application.

- Q: Can stainless steel pipes be coated with fusion bonded epoxy?

- Yes, stainless steel pipes can be coated with fusion bonded epoxy. This coating provides excellent corrosion resistance and improves the durability of the stainless steel pipes.

Send your message to us

durable and Reliable sus 309 stainless steel bar with quick delivery made in china

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords