Ductile Iron Pipe Professional Manufacturer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 199 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Ductile Iron Pipe Description :

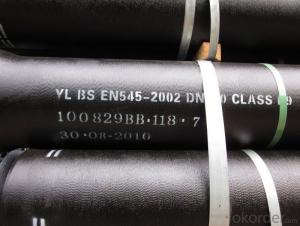

1) Pipes confirm to ISO2531,K9 class,T type joint,6m long,with inside cements lining conform to ISO4179, outside Zinc spraying(130g/m2) and bitumen coating(70μm) conform to ISO8179.

2) Pipe ends: Spigot and socket ends, with 100% SBR rubber gaskets

accoding to ISO4633

3) we can do third party inspection according to customer's request.

4) Our products have been sold to many international market,

such as Middle East and South East Asia and Africa.

2,Main Features of the Ductile Iron Pipe:

·High yield strength

·High tensile Strength

·High corrosion resistance

·Anti-corrosion

·Installation is convenient

·Satisfy the highest hygienic standards

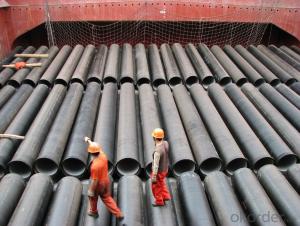

3,Ductile Iron Pipe Images:

4.FAQ:

We have organized several common questions for our clients,may help you sincerely:

Q: Why would you choose ductile iron pipe rather than other pipe materials?

A:The reasons are obvious for that not only ductile iron pipe possesses the inherent strength and flexibility of ductile iron, combined with proven corrosion protection systems, but also the cost savings can be achieved from design to installation and commissioning.

Q:Why can you guarantee the inner of pipes can’t be corroded?

A: High alumina cement mortar lining and sulphate-resistant cement mortar lining. These two special linings are applicable to inner anti-corrosion for sewage pipes, improving resistance to erosion of the sewage components.

- Q: Can ductile iron pipes be repaired if they are damaged?

- Yes, ductile iron pipes can be repaired if they are damaged. The extent of the damage will determine the type of repair that is needed. In cases where the pipe is cracked or has small holes, a repair clamp or a stainless-steel sleeve can be used to seal the damaged area. These methods provide a temporary fix and allow for the flow of water to continue until a more permanent repair can be made. For more severe damage, such as large cracks or broken sections, a full replacement may be necessary. This involves cutting out the damaged section of the pipe and installing a new piece. This process requires specialized equipment and expertise, but it can effectively restore the functionality of the pipe. It is important to note that the repair of ductile iron pipes should be carried out by trained professionals who have experience in working with this type of material. This ensures that the repairs are done correctly and do not compromise the integrity and safety of the pipeline system. Regular inspection and maintenance of ductile iron pipes can help identify any potential issues early on and prevent extensive damage that may require replacement rather than repair.

- Q: How long does the cast iron pipe of indoor direct buried sewage need to be examined?

- UPVC, also called hard PVC, is an amorphous thermoplastic resin made by polymerization of vinyl chloride monomer, with certain additives (such as stabilizers, lubricants, fillers, etc.). In addition to additives, the method of blending with other resins is also applied to make it have obvious practical value. These resins are CPVC, PE, ABS, EVA, MBS and so on. UPVC has high melt viscosity and poor flowability. Even if the pressure and melt temperature are increased, the fluidity is not changed. In addition, the molding temperature of the resin is very close to the thermal decomposition temperature, and the molding temperature range is very narrow. It is a difficult material to be formed.

- Q: What is the expected deflection of ductile iron pipes under load?

- The expected deflection of ductile iron pipes under load can vary depending on various factors such as the diameter, wall thickness, type of soil, and the magnitude and distribution of the load. However, generally speaking, ductile iron pipes are designed and manufactured to have minimal deflection under typical loads and are known for their high strength and stiffness.

- Q: Are ductile iron pipes suitable for underground applications?

- Yes, ductile iron pipes are suitable for underground applications. Ductile iron pipes are known for their durability, strength, and corrosion resistance, making them an ideal choice for underground installations. These pipes can withstand heavy loads, ground movement, and external pressure, making them suitable for burying underground. Additionally, ductile iron pipes have a long lifespan, often lasting more than 100 years, which is crucial for underground applications where accessibility and maintenance can be challenging. Overall, their robustness and longevity make ductile iron pipes a reliable and suitable choice for underground applications.

- Q: How does ductile iron pipe compare to steel pipe in terms of durability?

- Ductile iron pipe is generally considered to be more durable than steel pipe. It has superior strength and durability due to its unique microstructure, which allows it to withstand higher levels of pressure, impacts, and loads. Ductile iron pipe also has better corrosion resistance properties, making it less prone to rust and deterioration compared to steel pipe. Additionally, ductile iron pipe has a longer lifespan and requires less maintenance, making it a more reliable and durable choice for various applications.

- Q: How can the three pipes of ductile iron leak?

- When the pipe connection of the three water leakage, first of all to see whether it is to do the pipe three links of the manufacturers, pressure did not reach, if it is. It is only the replacement, if not, with cast iron electrode welding, or socket connection half!

- Q: Can ductile iron pipes be used in areas with high soil erosion?

- Yes, ductile iron pipes can be used in areas with high soil erosion. Ductile iron is known for its high tensile strength and durability, making it resistant to external forces such as soil erosion. It is a suitable choice for underground piping systems in such areas, providing long-term reliability and stability.

- Q: Can ductile iron pipes be used for river crossings?

- Yes, ductile iron pipes can be used for river crossings. Ductile iron is a strong and durable material that can withstand the stresses and pressures of being installed underground and crossing rivers. It is commonly used in water and sewage systems, including river crossings, due to its resistance to corrosion and its ability to handle high water pressure.

- Q: Is the crankshaft material forged or ductile iron?

- Cast iron can not be forged, only steel, malleable iron can not be forged, only the crankshaft is particularly hot, can not meet the strength of the hardening when forging

- Q: How are ductile iron pipes inspected for quality control?

- Ductile iron pipes are inspected for quality control through various methods such as visual inspection, hydrostatic pressure testing, dimensional checks, and non-destructive testing techniques like ultrasonic testing. These inspections ensure that the pipes meet the required specifications and standards, and any defects or abnormalities can be detected before installation or use.

Send your message to us

Ductile Iron Pipe Professional Manufacturer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 199 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords