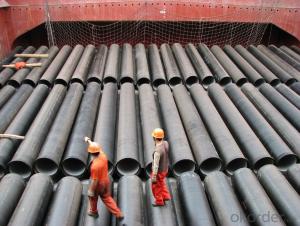

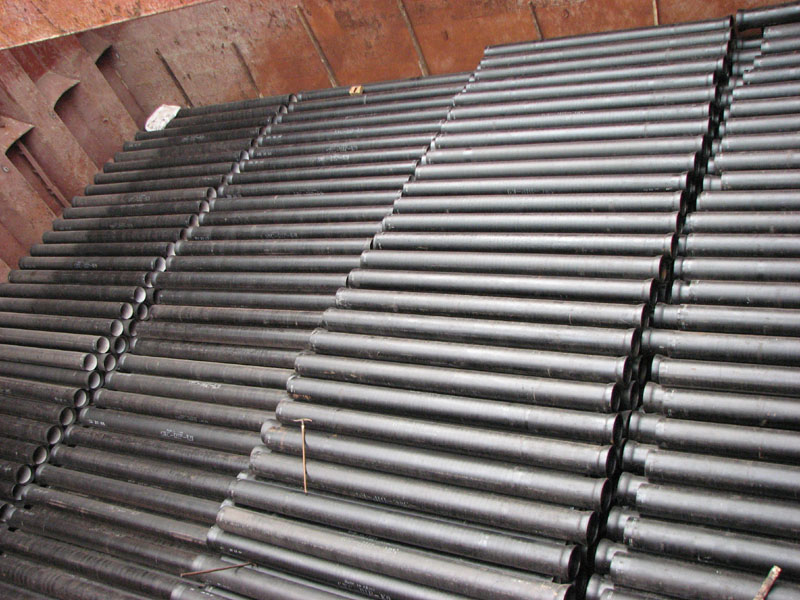

Ductile Iron Pipe On Sale From China with Top Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Place of Origin: China (Mainland)

Model Number: T type / K type / Flange type

Length: 6M/NEGOTIATED

Standard: ISO2531 and EN545

Application: Potable/Sewage Water

Diameter: DN80~DN1600

Shape: Round

Hardness: 230

Pipe Wall Thickness: STANDARD

Pull Strength: 420 Yield (≥ MPa): 300

Material: Cast Iron

Type: Ductile Iron Pipes

Certification: ISO2531 and EN545

Specification: DN80~DN1600

Outer Diameter: 80-1600

Thickness: standard

Usage: water pipe Packaging & Delivery

Packaging Details: DN80~DN300 are bundled with steel belts, others are in bulk condition.

Specification& Payment terms

Internal lining: Pipes shall have an internal cement mortar lining in acc with ISO4179.

External coating: Pipes shall be externally coated with metallic zinc spray plus a further layer of resin painting to ISO8179.

Gasket: 100% SBR/NBR/EPDM rubber gasket in accordance with ISO4633.

Packing: Pipes from DN100 to DN300 be bundled with steel belts, others are in bulk.

Payment term: L/C, T/T.

Packing: In bulk vessel or in container.

1. hydraulic hose crimping machine in Electrical equipment&supplies

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelt,and chemical industry.

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

2. Antiflaming,fire-resistance rubber hose assembly

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer and laye

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelts,and chemical industry

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

3. hydraulic hose Universal Wire-braided DN6

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

· Model Number: GB/T3683-92

Packaging & Delivery

Packaging Details: | hydraulic hose is wrapped with fabrics |

Delivery Detail: | 80000meters/30days |

Specifications

Universal Wire-braided Hydraulic Hose, Q/FLT01-AStandard GB/T3683-92, Temperature range: -40 to +100

Universal Wire-braided Hydraulic Hose

Q/FLT01-AStandard GB/T3683-92

Tube: oil resistant synthetic rubber

Reinforcement: 1 W/B (one high tensile steel wire braid)

Cover: abrasion and weather resistant synthetic rubber

Temperature range: -40 to +100.

4. Drilling Rubber Hose

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

Packaging & Delivery

Packaging Details: | Package: plastic films, then wrapped with fabrics |

Delivery Detail: | According to the Quantity |

Specifications

Drilling hose

DN |

Hose I.D | Wire O.D |

Hose O.D |

Working Pressure | Burst Pressure | Minimum Bend Radius | Weight | Length | |||

inch | mm | mm |

mm | MPa | psi | MPa | psi | mm | kg/m | metres | |

5 | 3/16 | 4.8 | 9.5 | 11.8 | 25.0 | 3630 | 100.0 | 14280 | 89 | 0.19 | 50/100 |

6 | 1/4 | 6.4 | 11.1 | 13.4 | 22.5 | 3270 | 90.0 | 12840 | 102 | 0.21 | 50/100 |

8 | 5/16 | 7.9 | 12.7 | 15.0 | 21.5 | 3120 | 85.0 | 12280 | 114 | 0.24 | 50/100 |

10 | 3/8 | 9.5 | 15.1 | 17.4 | 18.0 | 2615 | 72.0 | 10280 | 127 | 0.33 | 50/100 |

13 | 1/2 | 12.7 | 18.3 | 20.6 | 16.0 | 2320 | 64.0 | 9180 | 178 | 0.41 | 50/100 |

16 | 5/8 | 15.9 | 21.4 | 23.7 | 13.0 | 1890 | 52.0 | 7420 | 203 | 0.45 | 50/100 |

19 | 3/4 | 19.0 | 25.4 | 27.7 | 10.5 | 1530 | 42.0 | 6000 | 241 | 0.58 | 50/100 |

25 | 1 | 25.4 | 33.3 | 35.6 | 8.8 | 1280 | 35.0 | 5020 | 305 | 0.88 | 50 |

32 | 11/4 | 31.8 | 40.5 | 43.5 | 6.3 | 920 | 25.0 | 3600 | 419 | 1.23 | 20/40 |

38 | 11/2 | 38.1 | 46.8 | 50.6 | 5.0 | 730 | 20.0 | 2860 | 508 | 1.51 | 20/40 |

51 | 2 | 50.8 | 60.2 | 64.0 | 4.0 | 580 | 16.0 | 2280 | |||

5. Concrete pump rubber hose

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

Packaging & Delivery

Packaging Details: | Package: plastic films, then wrapped with fabrics |

Delivery Detail: | According to the Quantity |

Specifications

Specifications

High Quality Concrete Pump Delivery Rubber Hose

1.high quality

2.ISO9001:2008

3.reasonable price

1. Material: Black NR and BR synthetic rubber .

2.Reinforcement:Spiral textile/steel wire.

3. Widely application: Schwing PM SANY Zoomlion and other brand concrete pump trucks.

4.Cover:Abrasion resistantant,heat and ozone resistant.

5.Inside diameter:50-152mm

6.Working pressure:8.5 MPA.

7.Detailed specification:

No | Description | ID | OD | Plies | Working Pressure | Burst Pressure | Weight |

1 | 2 inch | 50mm | 70mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 3.5kgs |

2 | 2.5 inch | 63mm | 88mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 4.9kgs |

3 | 3 inch | 76mm | 102mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 6.5kgs |

4 | 4 inch | 100mm | 130mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 9.3kgs |

5 | 5 inch | 125mm | 155mm | 2 or 4 | 8.5MPA 1200PSI | 20MPA 3000PSI | 10.9kgs |

6 | 6 inch | 152mm | 184mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 13.3kgs |

- Q:How can the cast iron pipe of the ductile iron pipe be repaired?

- Get a pole. Or go around the corridor

- Q:What are the typical joint restraint systems used in ductile iron pipes?

- The typical joint restraint systems used in ductile iron pipes are mechanical joint restraints, push-on joint restraints, and restrained joint systems. These systems are designed to prevent pipe separation and movement at the joints, ensuring the integrity and stability of the pipeline.

- Q:What is the average diameter range of ductile iron pipes?

- The average diameter range of ductile iron pipes can vary depending on the specific application and industry standards. However, in general, ductile iron pipes are available in a wide range of diameters to meet various requirements. Commonly, the average diameter range for ductile iron pipes can start from as small as 4 inches (100 mm) and go up to 64 inches (1600 mm) or even larger. These sizes are often used for water distribution, sewer systems, and other infrastructure projects. It is important to note that the specific diameter range of ductile iron pipes can be influenced by factors such as local regulations, project specifications, and engineering considerations. Therefore, it is recommended to consult industry standards and relevant authorities to determine the appropriate diameter range for a specific application.

- Q:Can ductile iron pipes be used for agricultural applications?

- Yes, ductile iron pipes can be used for agricultural applications. Ductile iron is a strong and durable material that is resistant to corrosion, making it suitable for various agricultural purposes. These pipes can be used for irrigation systems, drainage systems, water supply systems, and other agricultural infrastructure projects. Ductile iron pipes have a high tensile strength and can withstand the external pressures and stress that may occur in agricultural environments. Additionally, they have a long lifespan, reducing the need for frequent replacements, and are capable of handling high water flow rates. Therefore, ductile iron pipes are a reliable choice for agricultural applications.

- Q:How to properly maintain FRP pipes

- The wall of the pipe is smoothReduce flow resistance, increase flow speed and reduce energy consumption. Compared with the same size steel pipe, the flow rate of the same volume can be increased by about 10%, and no fouling and long-term use can not reduce the flow rate. The protection of cables in interference and heavy corrosion environment is better.

- Q:How does ductile iron pipe perform in sandy or unstable soils?

- Ductile iron pipe performs exceptionally well in sandy or unstable soils due to its inherent strength and flexibility. The composition of ductile iron, which includes a combination of iron, carbon, and small amounts of other elements, gives it superior mechanical properties compared to other types of pipes. In sandy soils, where there is a risk of pipe movement and deformation due to shifting ground, ductile iron's high tensile strength and elongation characteristics allow it to withstand the pressure and stress without fracturing or breaking. Its flexibility enables it to accommodate the movement and settlement of the surrounding soil, reducing the risk of pipe failure. Moreover, ductile iron pipe's resistance to corrosion makes it highly suitable for installation in sandy soils. The protective lining and coatings applied to the interior and exterior of the pipe prevent the soil's corrosive elements from attacking the iron, ensuring long-term durability and reliability. In unstable soils with varying compaction levels or weak load-bearing capacity, ductile iron pipe's sturdy construction provides stability and support. Its robustness allows it to distribute the loads evenly, minimizing the risk of pipe deflection or collapse. Additionally, ductile iron pipe's joint design and sealing methods, such as push-on joints or mechanical joints with rubber gaskets, offer excellent leak resistance and prevent soil infiltration, further enhancing its performance in sandy or unstable soils. Overall, ductile iron pipe's combination of strength, flexibility, corrosion resistance, and reliable joint systems make it an ideal choice for applications in sandy or unstable soils, providing a long-lasting and efficient solution for water and wastewater transmission.

- Q:Do ductile iron pipes require special maintenance?

- Yes, ductile iron pipes do require special maintenance. While ductile iron is known for its strength and durability, it is still susceptible to certain forms of corrosion. Regular maintenance is necessary to prevent corrosion and prolong the lifespan of the pipes. This maintenance typically includes periodic inspections to check for any signs of corrosion or damage, as well as cleaning and protective coating applications. Additionally, proper handling and installation techniques should be followed to ensure the integrity of the pipes. Regular maintenance and adherence to industry best practices can help prevent leaks, breaks, and other issues, ultimately saving time and money in the long run.

- Q:Can ductile iron pipe be used for hot water applications?

- Indeed, hot water applications can make use of ductile iron pipe. Renowned for its robustness, longevity, and exceptional resistance to corrosion, ductile iron pipe proves itself ideal for diverse applications, including hot water systems. Its capability to withstand high temperatures and pressure renders it a dependable choice for the conveyance of hot water. Moreover, its thermal conductivity properties facilitate efficient heat transfer, guaranteeing the effective delivery of hot water throughout the system. Consequently, when evaluating materials for hot water applications, ductile iron pipe emerges as a fitting alternative.

- Q:What is the expected maintenance for ductile iron pipes?

- The expected maintenance for ductile iron pipes typically includes regular inspections for signs of corrosion or damage, cleaning to remove any sediment or debris buildup, and occasional repair or replacement of sections that are worn or compromised.

- Q:Are ductile iron pipes suitable for use in hydroelectric dams?

- Yes, ductile iron pipes are suitable for use in hydroelectric dams. They offer high strength, durability, and corrosion resistance, making them ideal for the harsh conditions found in dam environments. Additionally, ductile iron pipes have excellent hydraulic properties and can handle high water pressure, making them a reliable choice for transporting water in hydroelectric dams.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ductile Iron Pipe On Sale From China with Top Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords