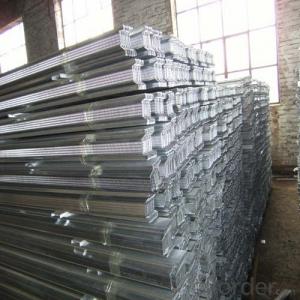

Drywall Metal Profile of Stud Zinc Galvanized

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

The products are made of galvanized strips with good rust-Proof function, and they are seen in hotels, theaters, factories, houses, emporiums, offices, airplane-terminal buildings, bus stations, etc..

C metal stud is faced with plasterboard

U metal track is installed along the floor to fix metal stud

Specification

Specification for middle east:

Main Channel | 38x12 mm |

Furring Channel | 68x35x22 mm |

Wall angle | 25x25 mm |

C stud | 50x35 mm |

C Stud | 70x35 mm |

C stud | 75x35 mm |

U track | 52x25 mm |

U track | 72x25 mm |

U track | 75x25 mm |

Specification to

top cross rail | 25x21x0.75 mm |

25x21x0.75 mm | |

Furring Channel | 28x38x0.55 mm |

16x38x0.55 mm | |

Furring Channel track | 28x20x30x0.55 mm |

16x20x30x0.55 mm | |

Stud | 64x33.5x35.5 mm |

76x33.5x35.5x0.55 mm | |

Stud | 92x33.5x35.5x0.55 mm |

150x33.5x35.5x0.55 mm | |

Track | 51x32x32, 64x32x32x0.55 mm |

76x32x32x0.55 mm | |

Track | 92x32x32x0.55 mm |

Specification to Europe,

C Stud | 60x27 mm |

U track | 28x27 mm |

C stud | 50x50 mm |

C stud | 75x50 mm |

C stud | 100x50 mm |

U track | 50x40mm |

U track | 75x40 mm |

U track | 100x40 mm |

Trade Shows

Main Markets: | 15.60% Southeast Asia |

13.2% Eastern Europe | |

12.3% Eastern Asia | |

12.00% North America | |

11.80% Mid East | |

10.8% Africa | |

9.50% South America | |

7.60% Oceania | |

6.70% Western Europe | |

Total Annual Sales Volume: | US$10 Million - US$50 Million |

Export Percentage | 51% - 60% |

Advantages and features:

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized steel strip zinc coating is 60-180g/m2.

3.Warm sales in Middle East , Africa ,

4. The specification can follow up customer requirements.

5. Advanced equipment can make sure exactly size, high quality products.

6.High quality cold rolled continuous hot galvanized plate as raw materials which makes sure it is anti-corrupt and anti-rusty

7.drywall steel profile adopts excellent manufacture equipment,advanced production process, scientific and detecting method.

8. Steel profile has beautiful surface, medium hardness! Good quality *competitive price large quantity *honesty *good after-service

Certificates ISO 9001:2000 Quality management system

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q: Can the interior walls be made of light steel keel partitions? Bathroom wall and interior wall with light steel keel wall is good or brick wall good?

- Light steel keel wall moisture resistance is poor, even with glass magnesium board, Ette board and other moisture-proof sheet, but still not suitable for high water requirements of the bathroom, there will be hidden.

- Q: Light steel keel wall how to install glass door

- And the normal installation of the same glass doors, but to consider the load-bearing, door frame to be reinforced, upstairs that useful wood panels are also available. However, we usually use the side tube to do support.

- Q: Light steel keel wall Why use gypsum board to do grass-roots level?

- It is not necessary to use gypsum board but gypsum board there are many other materials can not replace the advantages of easy paint on the paint, such as latex is also its weight is more suitable for the keel does not have too much pressure on the pressure there are other advantages One by one in detail the gypsum board used in light steel keel partition is a good choice

- Q: Shanghai light steel keel ceiling wall how much labor costs?

- If you buy materials to make people do not directly specify the material model specifications, directly called light steel keel, specifically do fast and good.

- Q: What is the light steel keel gypsum board partition? What are the characteristics?

- 1. Wall shrinkage deformation and board cracks: the reason is the vertical keel tight top and bottom keel, no extension of the amount of stretch, more than 2m long wall is not controlled deformation joints, resulting in wall deformation. The wall should be left around the gap 3mm, which can reduce the temperature and humidity caused by the deformation and cracks. 2. Light steel skeleton connection is not strong, because the local node does not meet the structural requirements, the installation of local nodes should be strictly in accordance with the provisions of the law. Nail spacing, location, connection method should meet the design requirements.

- Q: Is it possible to use a hollow brick or a 95 brick?

- With hollow bricks, because it is relatively light, will not cause the floor cracking. In fact, there are many other wall materials, including light steel keel gypsum board, steel mesh, etc., both light, but also save the space as usual when you decorate the brick wall should be used 1/2 brick wall, if the hollow brick Do, the wall width of the brush with 120 thick, the main advantage is the weight of light is generally 95 brick wall 2/3, will not bring too much burden on the structure of the house itself, noise effects can be, because the hollow brick inside Hole in the arrangements on the noise function to consider, relatively speaking, 95 brick wall thickness and hollow brick is the same, heavy weight, sound insulation effect than the hollow brick to slightly better. But I suggest that the main building brick wall, then the best use of steam concrete blocks, to achieve the best results!

- Q: House decoration, the designer said the wall with light steel keel good, but the construction told me that this low efficiency can only be maintained for 4,5 years so I do not know in the end listen to who

- Load on the best no problem with red brick, that wall how many square meters, if the area is less than 10 square meters can be brick 120 red brick wall

- Q: Waterproof gypsum board for toilet partition and paste tile installation steps?

- Bathroom wall on the calcium silicate board filled with less than 3CM steel mesh; fixed with a code nail gun; and then use 1: 3 of the cement mortar smear 2-3CM thick. After leveling the hair according to the normal process of paving wall.

- Q: Has installed a wooden floor, you can do in the above light steel keel wall?

- My advice is not to do on wooden flooring Because the wood floor is flexible. The The It is best to finish the wall, and then restore the floor Just personal opinion for reference only

- Q: 9 + 9 double gypsum board is what it means

- Gypsum board is a kind of material made of building gypsum as the main raw material. It is a light weight, high strength, thinner thickness, easy processing and insulation and fire insulation and other properties of better building materials, is currently focused on the development of one of the new lightweight sheet. Gypsum board has been widely used in residential, office buildings, shops, hotels and industrial plants and other buildings within the wall, wall panels (instead of wall plaster layer), ceilings, sound-absorbing panels, ground floor boards and the Such as decorative plates. Gypsum board gypsum board (divided into ordinary gypsum board (commonly used), fiber gypsum board, gypsum decorative plate "interpretation") it to gypsum as the main material, adding fiber, adhesive, modifier, Dry from. With fire, noise, heat, light, high strength, low shrinkage and other characteristics and good stability, not aging, anti-moth, available nails, saws, planing, sticky and other methods of construction.

Send your message to us

Drywall Metal Profile of Stud Zinc Galvanized

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords