Drywall constuction building material China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed product description:

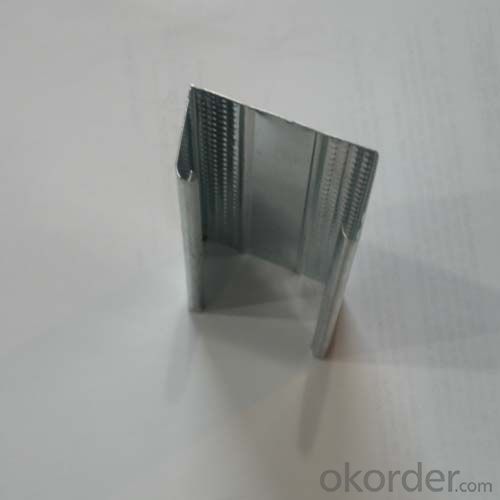

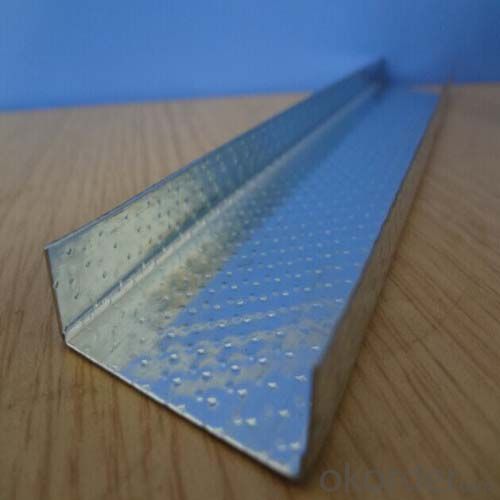

1) Item: W-35, 38 main channal, L angle, Connor Bead, DC-60, U-60, 50 Stud & track, 75 Stud and track, 100 Stud and track, ect.

2) thickness: 0.4-1.0mm

3) Length: 3000mm or dependes on customer's request

4) Zinc coating: 50-220g/m2 (depends on the customer's request)

5) Size as fellow form: (Width*Height*Thickness)

Product apply in: Mid East , Rusia, Europ, South America, Africa

Certificate for products:CE,stand :EN13964; ISO9001-2000

Specification

Specification for middle east:

Main Channel | 38x12 mm |

Furring Channel | 68x35x22 mm |

Wall angle | 25x25 mm |

C stud | 50x35 mm |

C Stud | 70x35 mm |

C stud | 75x35 mm |

U track | 52x25 mm |

U track | 72x25 mm |

U track | 75x25 mm |

Specification to Australia:

top cross rail | 25x21x0.75 mm |

25x21x0.75 mm | |

Furring Channel | 28x38x0.55 mm |

16x38x0.55 mm | |

Furring Channel track | 28x20x30x0.55 mm |

16x20x30x0.55 mm | |

Stud | 64x33.5x35.5 mm |

76x33.5x35.5x0.55 mm | |

Stud | 92x33.5x35.5x0.55 mm |

150x33.5x35.5x0.55 mm | |

Track | 51x32x32, 64x32x32x0.55 mm |

76x32x32x0.55 mm | |

Track | 92x32x32x0.55 mm |

Specification to Europe, Russia, UKrain, Georgia. etc

C Stud | 60x27 mm |

U track | 28x27 mm |

C stud | 50x50 mm |

C stud | 75x50 mm |

C stud | 100x50 mm |

U track | 50x40mm |

U track | 75x40 mm |

U track | 100x40 mm |

Product Overviews

Advantages and features:

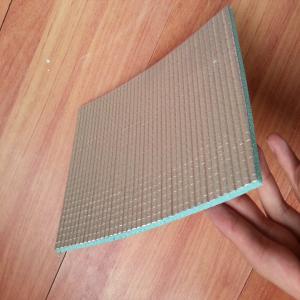

Excellent fire resistive ability. Suit residuals and public places.

Fast installation. Easy to control the construction progress

Combinative construction. Easy to keep work places clean.

Good vibration absorbing ability. Suit buildings on seismic belt.

Fast reconstruction for easy assembling and dismantling.

Filling acoustic insulation can enhance the sound-proof ability.

Surface of the walls are smooth. Easy to paint or paste wallpaper.

Electric wires are hidden in the wall

It is easy to drill through the wall for construction.

It could be applied under the original ceiling

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q: Light steel keel partition wall fire retardant coating shabu several surface

- Best four times, at least twice. I hope my solution will help you

- Q: Who used the light steel keel gypsum board to do the wall?

- The sound insulation effect than the brick or a little worse but have their own advantages and disadvantages of the small space that is also cheaper than the brick wall is suitable for wardrobe compartment

- Q: Shanghai light steel keel ceiling, wall quotes

- Not material money, the wall is generally single to 12 to 18 yuan per square meter, double 18 to 24 yuan per square meter. Ceiling 20 yuan per square meter

- Q: Is it good for brick walls or light walls?

- Each have their own benefits ah Brick wall is more sound and more solid friends Light wall, then light, do not take up a lot of space to remove or remove

- Q: Light steel keel wall Why use gypsum board to do grass-roots level?

- It is not necessary to use gypsum board but gypsum board there are many other materials can not replace the advantages of easy paint on the paint, such as latex is also its weight is more suitable for the keel does not have too much pressure on the pressure there are other advantages One by one in detail the gypsum board used in light steel keel partition is a good choice

- Q: Is it possible to use a hollow brick or a 95 brick?

- Decoration in the practice of a lot of walls, in addition to brick, you can also use light steel keel plus gypsum board practice and so on, the key is to look at the area of the wall surrounded by how much, in what position, use, etc., then To decide the wall of the program.

- Q: House decoration, the designer said the wall with light steel keel good, but the construction told me that this low efficiency can only be maintained for 4,5 years so I do not know in the end listen to who

- But in a dry place, with a 20 years no problem, light steel keel life and its wall thickness, sealing plate varieties and thickness are closely related. Do not worry about the damp environment, it is recommended to use light steel keel partition, after all, it has light, space-saving, construction convenience, the cost is relatively low advantage.

- Q: Can the gypsum board be painted on the wall

- If the light can be linked to the screw with a self-tapping screw, hanging 2-3 kg should be no problem

- Q: Light steel keel + gypsum board + surface brush latex paint partition wall per square meter offer is how much?

- Too general, and the regional difference, the amount of engineering, high-level factors led to a large spread. General tooling: light steel keel material 25 + artificial 20, gypsum board material 12 + artificial 8, scraping putty latex paint three times material 18 + artificial 12, gypsum board and latex paint count double. With auxiliary materials estimated total price of 150 or so.

- Q: Light steel keel wall cheap or cheap red brick

- Of course, is the light steel keel, probably in 70 a square, wall, then 12 of the wall art manual brick is 80, double-sided batch of 30, is 110!

Send your message to us

Drywall constuction building material China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords