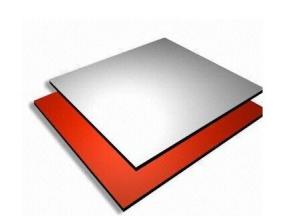

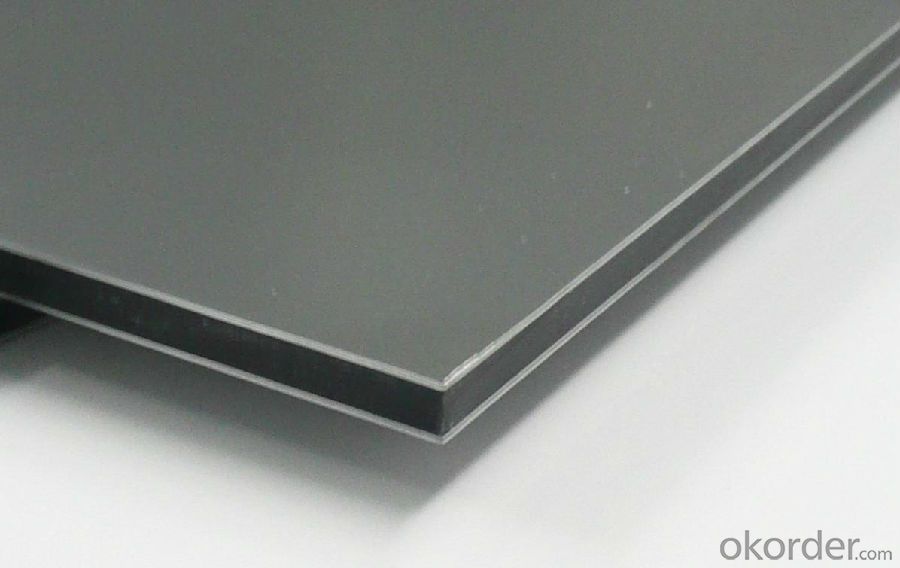

Double Sides Glossy Color Pvdf Aluminum Composite

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Double Sides Glossy Color Pvdf Aluminum Composite

1. Standard:

according to GB/T 17748-1999 standard

2. Material:

a) Front: aluminum alloy sheet coated with fluoro-carbon resin

(PVDF) and polyester resin (PE) roasting painting

b) Core: nontoxic polyethylene.

c) Back: aluminum alloy sheet coated with polyester resin painting

d) Surface finish: treated with PVDF and PE resin rolling roasting .

coating

e) Surface coating thickness: 30um

f ) Aluminum alloy sheet thickness: 0.1mm, 0.12mm, 0.15mm, 0.2mm,

0.3mm, 0.4mm, 0.45mm, 0.5mm

3. Dimensions:

a) Thickness: 3mm, 4mm

b) Width: 1220mm 1500mm..

c) Length: 2440mm, 3200mm, 4000mm,5000mm (max: 6 meter)

d) Weight: 5.5kg/sqm based on 4mm thickness.

e) Standard size: 1220 x 2440mm

f) Nonstandard sizes are available according to requirement of customers

4. Application scope:

1) Building exterior curtain walls..

2) Decoration and renovation additions for old buildings

3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies

4) Shop door decorations

5) Advertisement board display platforms and signboards

6) Wallboards and ceilings for tunnels..

7) Industrial materials, materials for vehicles and boats

Production Machinery:

| Machine Name | Brand & Model No. | Quantity | Number of Year(s) Used | Condition |

|---|---|---|---|---|

| Coating line | WANGUAN | 2 | 4.5 | Acceptable |

| Aluminum plastic composite line | FB1600 | 4 | 3.5 | Acceptable |

| Embossing line | No information | 1 | 1.0 | Acceptable |

Testing Machinery:

| Machine Name | Brand & Model No. | Quantity | Number of Year(s) Used | Condition |

|---|---|---|---|---|

| Bending machine | No information | 1 | 8.0 | Acceptable |

| Visual comparison of the colour device | MSBS-1 | 1 | 5.0 | Acceptable |

| Drying oven | PULUO | 1 | 5.0 | Acceptable |

- Q: New house I would like to all use aluminum-plastic panels such as kitchen, door, edge line, cut off. Do not know whether or not, the specific price of how much, there is no pollution, decoration costs are generally much. Thank you!

- In general, aluminum-plastic panels are mainly used for wall skirts, ceilings, kicks and pillars and other shapes, the most suitable part is the door, you can do the door sets, window sets. Kitchen or with tiles better, easy to clean.

- Q: What are the materials for making aluminum-plastic panels?

- Polyethylene core plastic polymer film Lvpi paint protective film

- Q: Meizhou how to sell outdoor aluminum plate? Please contact the contact, QQ and so on

- Located in Shunde: Guangdong Li Kyle Industrial Co., Ltd. specializing in the production of "Lee Kyle card" "Auspicious licensing" aluminum-plastic panels, aluminum veneer. Contact in space.

- Q: I want to open a small aluminum-plastic plate factory, how much money

- Production of aluminum-plastic board products, the need for pretreatment, painting, composite three sets of equipment, this down 800,000 on it, if it is a small factory, then you can find third-party manufacturers to paint, you can only on the composite line, so Single equipment 50 million enough.

- Q: Aluminum-plastic curtain wall construction in winter, with the real paste can you?

- The temperature is obviously different, then the impact on the construction will be very different.

- Q: I would like to ask the next aluminum plate, aluminum veneer and aluminum composite panels are three characteristics

- Aluminum veneer generally refers to the thickness of 1.5mm or more aluminum.

- Q: Which brand is strong?

- Aluminum mineral composite panels focus on the advantages of aluminum and mineral wool board: environmental protection, sound insulation, waterproof and dustproof, impact resistance, easy to change color. Yi Bo Shi aluminum composite panel with 50% of the traditional aluminum veneer composite mineral wool board, fully integrated mineral wool board itself, the strength of the pressure and aluminum plate to achieve a substantial increase in plate flatness and impact resistance. But also the use of aluminum and the characteristics of the scrub can make the plate looks more than ordinary mineral wool board texture, maintenance and more simple. Ordinary perforated aluminum slab plate installed inside and outside the air will be convection, increase the volume of cold and warm space, a waste of energy. The easy Bo Shi aluminum composite panel of the three-tier design, mineral wool layer and aluminum foil layer can effectively block the air convection, so as to achieve the purpose of energy saving, but also play a very good sound-absorbing effect. Easy to Boshi aluminum mineral composite board products, with energy saving, environmental protection, sound absorption, heat insulation, waterproof and clean, strong impact resistance (surface to take polyester paint) no color, no color and other characteristics, is to lead Fashion trend of the new building decoration products. Aluminum mineral wool composite sound absorption board products are widely used in shopping malls, office buildings, hotels, schools, factories, hospitals, banks, conference rooms, stadiums, airports and other public places

- Q: What are the specifications of aluminum-plastic plates?

- Length: Standard length is 2440. Can also be customized according to customer requirements such as: 2000,3000,3200, etc., the length is generally not limited, but requires convenient transportation. The unit is mm.

- Q: Is the aluminum-plastic board protective film toxic?

- Aluminum plastic plate life is short, good antioxidant capacity, are generally used in the door or store decoration, home improvement generally do not use aluminum-plastic plate. If you take into account the environmental protection, it is recommended to use your favorite panel and then brush on the favorite color.

- Q: RT, I think these two are not the same thing? But, it seems not, we take this to do the printing, and now use the composite aluminum-plastic plate, but UV inkjet, will be out, others use aluminum Plastic composite panels, will not fall, so I think these two are not the same thing, please give guidance, these two kinds of relations, why, ...

- These two kinds of things is a kind of material is the aluminum composite plate you will be sprayed out because you use the paint is not dedicated so it will fall If you want to spray the other side of the original aluminum coating on the color can not afford to suggest you Consult you to buy the manufacturers so that he can not provide you with the raw materials do not go to the market to buy a common inkjet paint that is not because the aluminum-plastic plate on the coating and then spray something but not to go through a special treatment of paint can Otherwise it will not be how long it is best to dry from the dry paint

Send your message to us

Double Sides Glossy Color Pvdf Aluminum Composite

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords