Dope dyed black polyester fdy 100/36 600tpm twisted warp yarn in china

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Info

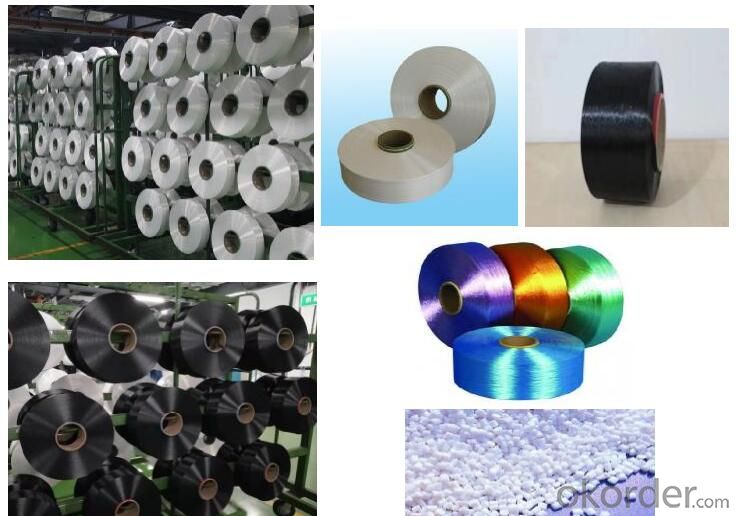

Product name: FDY 1000D HIGH TENACITY INDUSTRIAL YARN

Material: 100% Polyester

Pattern: dope-dyeing

Yarn Type: FDY, Filament

Feature: Eco-Friendly, Recycled, High Tenacity

Use: Weaving, Knitting, Sewing , Weaving , Knitting

Twist: S/Z TWIST

Evenness: EVEN

Color: white , black

MOQ: 30 KGS

Quality: AA Grade

Package: Pallet

Package Type: 4bobbins/carton, 10KG/bobbin, 40KG/cartons, 12 tons/20gp, 24 tons/40HQ

Certification: GRS, TC, OEKO

Keywords: Recycled FDY yarn, R-pet yarn, Eco-Friendly yarn

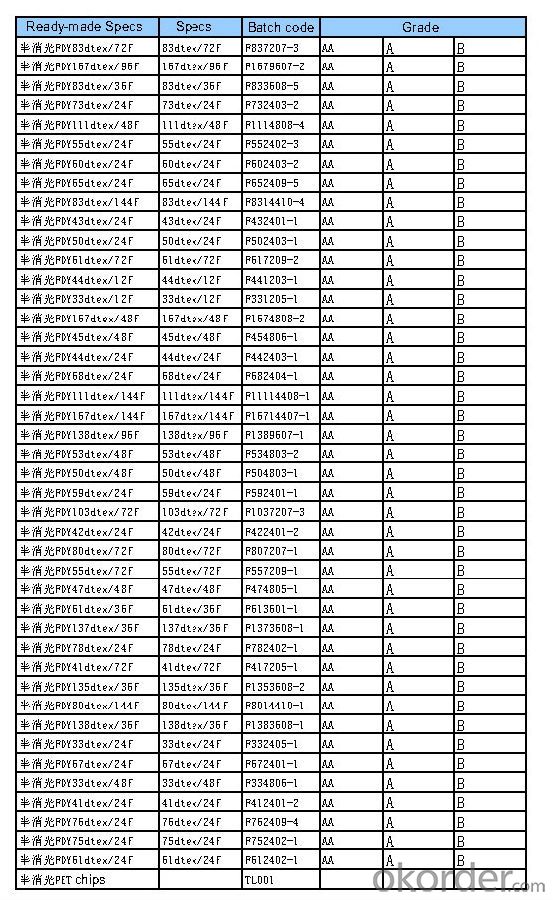

Regular Specifications

Feature:

Low melting polyester will be melted at 110/180 degree Celsius and be endowed with adhesive property.

Use low melting polyester is harmless, and enhances the strength of the fabric.

The fabric made with low melting polyester yarn is with high strength, washable, stiff and smooth, easy care.

Low melting polyester yarn owns good adhesiveness and stability, adhesive quickly.

The processing is simple, low energy consumption, nonhazardous, no pollution, Eco-friendly.

Application and suggestion:

1. The adhesive of two layers of sports shoe Upper material —FDY 50D/75D

2. Soft curtain, Zebra curtain, Roman curtain—FDY 75D/150D

3. Vertical blinds—FDY 250D

4. Filter net for air condition—FDY 30D/50D/75D/150D

5. Electromagnetic wire: PET-Glass fiber blended fiber—FDY 50D/75D

6. Garment lining cloth for suit, tie, hat, etc. —FDY 150D/50D/420D

7. Warp knitting fabric such as: Stiff mesh fabric, medical/food filter net, inner car decoration.

8. Top-grade eco-friendly filter material

9. Other applications: protective gloves, dust gauze, top-grade window screen, invisible screen, etc.

- Q: Why in general the yarn in the woven fabric strength coefficient of use greater than 1

- 2. Use Cotton yarn is widely used, it can be used as woven yarn, can also be used as knitting yarn, especially combed yarn can be used to produce high quality textile products, such as high-grade T-shirt, fine poplin, cotton Can produce special industrial ...

- Q: What is the cheese yarn?

- Usually called "cheese yarn"; size - such as diameter about ∮ 250mm or so, the height of about 150mm or so different specifications, requiring no joints (air splicing) or small and fast joints, and forming a good internal and external tension evenly.

- Q: How does textile twist yarn identify?

- Observe the fiber near the flame, contact with the flame, leaving the flame produced by a variety of different phenomena and the combustion of the odor, the post-combustion residue to identify the fiber type.

- Q: What is Artex and Artex Products?

- Analysis of the industry that, with the improvement of living standards and aesthetic concepts, foreign Artex product market will be further expanded, the development potential is huge.

- Q: What are the differences between the yarn and the yarn of the yarn?

- 2. Processing of cotton yarn manufacturing methods are more complex, in general, there are two kinds of spinning methods, that is, cotton spinning and combing spinning. (1) carding cotton spinning process: with cotton → open cotton → carding → → → → roving → yarn → post-processing → finished product inspection. (2) combing spinning process: with cotton → open cotton → carding → combing → parallel → roving → spun yarn → post-processing → finished product inspection.

- Q: What is the number of yarns used in cotton textiles to mean what is meant

- The fineness of the yarn (in English): refers to a pound (454 grams) of heavy cotton yarn in the provisions of moisture regain, there are several 840 yards (1 yards = 0.941 meters) long, that is, a few miles of yarn, As "a few yarn", the unit with "S" said. The larger the number in front of S, the finer the yarn, the lighter, thinner, and softer the fabric. The smaller the number, the thicker the yarn, the heavier the fabric, the thicker and the more rough.

- Q: What is the reason for the low strength of cotton yarn

- We have experimented with the increase in the twist of the tube after passing through the windings, and the control of the normal spun yarns is about 340-350.

- Q: On the number of textile yarns

- Simply said that the length of the unit weight, the longer the length will be fine, so the greater the number of yarn the more thin!

- Q: Forming Principle of Yarn of Textile Industry

- Steel ladder in the older models is completed by iron cannon, that is, a designed iron arc to guide the steel lift, a bit similar to the cam mechanism. But now some new models, such as 1502, there are special molding agencies, I think it should be computer control, and is a separate variable frequency motor drag

- Q: How to reduce the cost of textile yarn dyeing

- 3, water and electricity state control, you can not save 4, the equipment is the previous, and now do not expand the scale, for the time being

Send your message to us

Dope dyed black polyester fdy 100/36 600tpm twisted warp yarn in china

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords